This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3634299 Flexible Hose is a component designed for use in commercial trucks, manufactured by Cummins Inc. This hose is integral to the operation of truck systems, facilitating the transfer of fluids and contributing to the overall efficiency and reliability of the vehicle. Flexible hoses are vital in the automotive industry, providing a means to connect various systems while accommodating movement and vibration inherent in vehicle operation 1.

Basic Concepts of Flexible Hoses

Flexible hoses are conduits used in vehicles to transport fluids such as coolant, fuel, and hydraulic fluid. They are designed to withstand pressure, temperature variations, and the dynamic environment within a vehicle. These hoses are typically made from materials like rubber, thermoplastic, or a combination of fabric and rubber, chosen for their flexibility, durability, and resistance to environmental factors 2.

Purpose of the Cummins 3634299 Flexible Hose

This part serves a specific function in the operation of a truck by connecting systems that require fluid transfer. It is engineered to transport fluids between components that may move relative to each other, ensuring a continuous and secure flow. This hose is part of a system that relies on its flexibility and durability to maintain performance under varying conditions 3.

Key Features

The 3634299 Flexible Hose boasts several key features that enhance its performance and durability. Its design incorporates materials that provide resistance to wear and environmental factors. The construction includes layers that offer strength and flexibility, allowing it to withstand the pressures and movements associated with truck operations. Unique attributes may include reinforced ends for secure fitting and a smooth inner lining to facilitate fluid flow.

Benefits

Utilizing this Cummins part in commercial trucks offers several advantages. Its improved flexibility allows for greater movement between connected components, reducing the risk of damage from vibration or shifting. The hose’s resistance to wear and tear ensures longevity, even under demanding conditions. Additionally, its compatibility with various truck systems makes it a versatile choice for fleet maintenance and upgrades.

Installation Considerations

Proper installation of the 3634299 Flexible Hose is crucial for optimal performance and safety. Guidelines for installation include ensuring correct fitting to prevent leaks and securement methods that accommodate the dynamic environment of truck operations. Attention to these details helps maintain the integrity of the fluid transfer system and the overall reliability of the vehicle.

Troubleshooting Common Issues

Common problems with flexible hoses, such as leaks, kinks, and degradation over time, can affect vehicle performance. Troubleshooting steps may involve inspecting the hose for signs of wear, ensuring proper installation, and replacing the hose if damage is detected. Regular checks can help identify issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 3634299 Flexible Hose is recommended to prolong its lifespan and ensure reliable operation. Maintenance routines should include inspection for signs of wear, such as cracks or softening of the material, and checking for proper fitting and securement. Early detection of wear signs can indicate the need for replacement, preventing potential failures in the fluid transfer system.

Cummins Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industry, with a history of innovation and commitment to quality in manufacturing automotive components. The company’s extensive range of products, including the 3634299 Flexible Hose, reflects its dedication to providing reliable and high-performance solutions for the transportation sector.

Cummins Engine Part 3634299: Flexible Hose Compatibility

The Cummins part 3634299, a Flexible Hose, is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and durability. This part is engineered to meet the specific needs of the engines it is intended for, providing a reliable connection that can withstand the rigors of heavy-duty operations.

K19, K50, V28 Engines

The Flexible Hose part 3634299 is compatible with the K19, K50, and V28 engines. These engines are known for their robust construction and efficiency, making them suitable for a range of applications from construction to transportation. The hose’s flexibility and durability ensure it can handle the dynamic stresses and varying conditions these engines encounter.

QSK38 CM850 MCRS, QSK50 CM2150 MCRS, QSK50 CM2350 K108 Engines

For the QSK38 CM850 MCRS, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines, the part 3634299 is engineered to provide a precise fit. These engines are part of Cummins’ QSK series, which is renowned for its power and reliability in demanding environments. The flexible hose ensures that the connections within these engines remain secure and efficient, even under high-pressure conditions.

The compatibility of the part 3634299 with these engines underscores Cummins’ commitment to providing high-quality components that enhance engine performance and longevity. Whether used in industrial, marine, or power generation applications, this flexible hose is a critical component that ensures the smooth operation of these powerful engines.

Role of Part 3634299 Flexible Hose in Engine Systems

The part 3634299 Flexible Hose is integral to the efficient operation of various engine systems. It facilitates the transfer of fluids and gases between components, ensuring seamless functionality and performance.

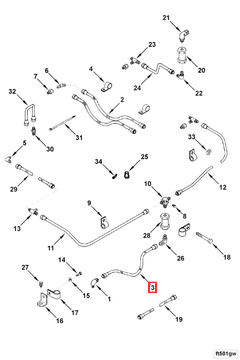

Actuator Bosch Plumbing

In actuator Bosch plumbing systems, the flexible hose allows for the dynamic movement of hydraulic fluids. This is essential for the actuator’s operation, which relies on precise fluid delivery to function correctly. The hose’s flexibility accommodates the mechanical movements within the system, reducing the risk of leaks and ensuring consistent performance.

Bosch Actuator Plumbing

Similarly, in Bosch actuator plumbing, the hose plays a vital role in connecting the actuator to the fluid supply. Its flexibility ensures that the actuator receives a steady flow of hydraulic fluid, which is necessary for its accurate and responsive operation. This connection is particularly important in systems where the actuator needs to move through a range of positions.

Corrosion Resistor Arrangement

Within the corrosion resistor arrangement, the flexible hose is used to route coolant or other protective fluids. This helps in maintaining the temperature and preventing corrosion of sensitive components. The hose’s material is typically selected to resist corrosion itself, further enhancing the system’s longevity and reliability.

Corrosion Resistor Head

The hose connects to the corrosion resistor head, ensuring that the fluid reaches the head without restriction. This is important for the head’s function in dissipating heat and protecting other engine components from corrosive elements. The flexibility of the hose allows it to conform to the engine’s layout, facilitating a secure and efficient connection.

Filter, Full Flow Oil

In the full flow oil filter system, the flexible hose transports oil from the sump to the filter and then to the engine components. This ensures that the engine receives clean, filtered oil, which is essential for lubrication and reducing wear. The hose’s flexibility accommodates the engine’s movements and vibrations, maintaining a consistent oil flow.

Fuel Supply Tubing

For fuel supply systems, the flexible hose is used to connect the fuel tank to the engine’s fuel injection system. This ensures a reliable and uninterrupted fuel supply, which is necessary for the engine’s combustion process. The hose’s flexibility helps in managing the dynamic nature of the fuel system, preventing kinks and blockages.

Fuel Tubing

In fuel tubing applications, the hose facilitates the transfer of fuel from the tank to the engine. Its flexibility is crucial in accommodating the vehicle’s movements and ensuring that the fuel line remains intact and functional under various driving conditions.

Governor, Fuel

The flexible hose in the fuel governor system ensures that the governor receives a consistent fuel supply. This is important for the governor’s role in regulating the engine’s speed and performance. The hose’s flexibility allows it to adapt to the engine’s layout and movements, ensuring reliable fuel delivery.

Head Corrosion Resistor

Connecting to the head corrosion resistor, the flexible hose ensures that protective fluids reach the head, helping to maintain its integrity and function. This is particularly important in environments where corrosion is a significant concern, as the hose helps in delivering the necessary protective fluids efficiently.

Plumbing, Fuel Supply

In the overall fuel supply plumbing, the flexible hose is a key component in routing fuel from the tank to the engine. Its flexibility ensures that the fuel line can adapt to the vehicle’s structure and movements, providing a reliable and consistent fuel supply.

Resistor, Corrosion

Finally, in corrosion resistor systems, the flexible hose is used to deliver fluids that protect against corrosion. Its role is to ensure that these fluids reach all necessary components, helping to extend the lifespan of the engine and its parts by preventing corrosive damage.

Conclusion

The Cummins 3634299 Flexible Hose is a critical component in the operation of commercial trucks, offering flexibility, durability, and compatibility with various engine systems. Its role in facilitating fluid transfer ensures the efficient and reliable performance of truck systems. Proper installation, regular maintenance, and timely replacement are essential to maximize the benefits of this part and ensure the longevity and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.