This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3634313 Flexible Hose is a component designed for use in commercial trucks. It serves as a vital link in various systems within these vehicles, facilitating the transfer of fluids and contributing to the overall efficiency and reliability of truck operations.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are constructed from materials that allow them to bend and flex without compromising the flow of fluids or gases. Within a system, flexible hoses help to absorb vibrations, reduce stress on connections, and provide a more adaptable solution compared to rigid pipes 1.

Purpose of the 3634313 Flexible Hose

The Cummins 3634313 Flexible Hose is engineered to play a specific role in the operation of a truck. It connects various systems and transports fluids that are essential for the truck’s performance. This hose is typically used in applications where flexibility and durability are required to withstand the dynamic environment of a commercial truck.

Key Features

The Cummins 3634313 Flexible Hose is characterized by several primary features that enhance its performance. These include a material composition designed for resilience, flexibility that allows it to accommodate movement and vibration, durability to resist wear and tear, and design elements that ensure a secure and leak-free connection within the truck’s systems.

Benefits

The Cummins 3634313 Flexible Hose offers several advantages. Its flexibility allows for better accommodation of the movement and vibration inherent in truck operations compared to rigid pipes. This reduces the stress on connected components and contributes to a longer service life. Additionally, its durable construction ensures reliable performance even in harsh operating conditions 2.

Installation Considerations

When installing the Cummins 3634313 Flexible Hose, it is important to follow best practices to ensure proper function and longevity. This includes ensuring compatibility with other truck components, using the correct fittings, and following manufacturer guidelines for secure and leak-free connections. Potential challenges during installation may include fitting the hose in tight spaces or ensuring it can accommodate the full range of movement expected in operation.

Troubleshooting Common Issues

Flexible hoses, including the Cummins 3634313, may encounter issues such as leaks or wear over time. Diagnosing these problems involves inspecting the hose for signs of damage, checking connections for leaks, and assessing the hose’s flexibility and integrity. Resolutions may include repairing or replacing the hose, ensuring proper installation techniques are used, and addressing any underlying issues that may contribute to hose failure.

Maintenance Tips

Regular maintenance of the Cummins 3634313 Flexible Hose is key to ensuring its longevity and reliable performance. This includes periodic inspections for signs of wear or damage, checking for leaks, and ensuring all connections are secure. Care procedures may involve cleaning the hose and its connections, and replacing the hose if it shows significant signs of wear or if it has reached the end of its service life.

Safety Precautions

When working with the Cummins 3634313 Flexible Hose, it is important to observe safety measures to protect both the technician and the equipment. This includes handling the hose with care to avoid damage, using appropriate tools and equipment during installation or repair, and following all safety guidelines provided by the manufacturer.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications, including commercial trucks.

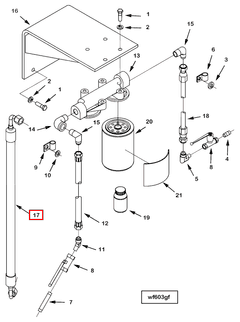

Cummins Flexible Hose 3634313 in Engine Applications

The Cummins Flexible Hose part number 3634313 is a critical component in various engine configurations, ensuring efficient fluid transfer and system integrity. This hose is designed to accommodate the dynamic movements and thermal expansions that occur within the engine compartment, providing a reliable connection between different parts of the engine system.

K38 Engine Series

In the K38 engine series, the Flexible Hose 3634313 plays a pivotal role in maintaining the operational efficiency of the engine. This hose is typically used in applications where it connects the fuel system components, such as the fuel pump to the fuel filter, or other fluid transfer points that require flexibility and durability. Its design allows it to withstand the high pressures and temperatures inherent in engine environments, ensuring that the engine operates smoothly and efficiently.

The hose’s flexibility is particularly important in the K38 engines, where the engine’s design may involve complex layouts and tight spaces. The 3634313 hose is engineered to provide a seamless connection, minimizing the risk of leaks and ensuring that the fluid flow is not impeded. This is crucial for maintaining the engine’s performance and longevity.

The use of the Cummins Flexible Hose 3634313 in the K38 engines underscores the importance of high-quality components in engine design. By choosing a hose that can handle the rigors of engine operation, manufacturers ensure that the engine can perform reliably under a variety of conditions. This attention to detail in component selection is a hallmark of Cummins’ commitment to quality and durability in their engine products.

Role of Part 3634313 Flexible Hose in Engine Systems

Part 3634313 Flexible Hose is integral to the efficient operation of various engine systems. It facilitates the transfer of fluids between components while accommodating the dynamic movements and vibrations inherent in engine operation.

In conjunction with the Corrosion Resistor Head, the flexible hose ensures that the fluid pathways remain intact and uncompromised, even under conditions of thermal expansion and contraction. This partnership is vital for maintaining the integrity of the fluid transfer system, which is essential for the consistent performance of the engine.

When integrated with the Corrosion Resistor Mounting, the flexible hose provides a secure yet flexible connection. This allows for the necessary adjustments and movements without risking detachment or failure, thereby enhancing the durability and reliability of the engine system.

The collaboration with the Resistor component ensures that the electrical and fluid systems within the engine can operate harmoniously. The flexible hose’s ability to bend and flex without kinking or breaking is essential for maintaining the flow of fluids, which is often necessary for cooling, lubrication, or other critical functions.

Finally, the interaction with the Corrosion protection elements underscores the importance of the flexible hose in preserving the longevity of the engine components. By providing a resilient and adaptable connection, it helps to prevent the buildup of corrosive substances that could otherwise lead to degradation and failure of the engine parts.

Overall, part 3634313 Flexible Hose plays a significant role in ensuring the smooth and efficient operation of engine systems by providing flexible, secure, and durable fluid pathways.

Conclusion

The Cummins 3634313 Flexible Hose is a critical component in the operation of commercial trucks and engine systems. Its design and features ensure efficient fluid transfer, system integrity, and reliable performance under various operating conditions. Regular maintenance, proper installation, and adherence to safety precautions are essential for maximizing the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.