This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3634470 Flexible Hose is a component designed for use in commercial truck systems. It serves as a conduit for various fluids, facilitating their transfer between different parts of the truck’s system. This hose is integral to maintaining the operational efficiency of the truck by ensuring reliable fluid transport 1.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without compromising their structural integrity or the flow of the substances they carry. In automotive systems, these hoses are used to connect rigid pipes and components that may move or vibrate during operation. They accommodate movement and reduce stress on the connected parts, which helps prevent leaks and component failure 2.

Purpose of the Cummins 3634470 Flexible Hose

This Cummins part is specifically designed to connect various systems within a truck, such as the fuel, coolant, or hydraulic systems. It transports fluids like fuel, coolant, or hydraulic fluid, ensuring that these systems operate correctly. The hose’s flexibility allows it to withstand the vibrations and movements typical in a truck’s operating environment, which is crucial for the consistent performance of the connected systems 3.

Key Features

The 3634470 Flexible Hose is constructed from materials that offer durability and flexibility. Its design includes reinforced layers to withstand pressure and abrasion, and it may feature unique characteristics such as heat resistance or specific bend radius capabilities to enhance performance in demanding conditions. These features contribute to the hose’s longevity and reliable operation within the truck’s system 4.

Benefits

This part provides several advantages. Its flexibility reduces the risk of kinking and allows for easier installation in tight spaces. The hose’s resistance to wear and tear, along with its ability to handle various fluids, enhances the safety and efficiency of the truck’s fluid transfer systems. Additionally, its design contributes to a reduction in maintenance needs and operational downtime.

Installation Considerations

When installing the 3634470 Flexible Hose, it is important to ensure proper fitting to prevent leaks and maintain system integrity. Securement methods should be employed to keep the hose in place and prevent it from moving excessively, which could lead to wear or disconnection. Compatibility with existing systems must be verified to ensure that the hose fits within the truck’s design and operates as intended.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these problems, one should inspect the hose for signs of wear, ensure that all connections are secure, and replace the hose if it shows significant degradation. Regular checks can help identify potential issues before they lead to system failure.

Maintenance Tips

To ensure the longevity and reliable performance of the 3634470 Flexible Hose, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, checking for proper securement, and replacing the hose according to the manufacturer’s guidelines or when signs of degradation are present. Adhering to a maintenance schedule can help prevent unexpected failures and extend the service life of the hose.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various industries, including transportation, construction, and agriculture.

Cummins Part 3634470: Flexible Hose Compatibility

This Cummins part is designed to fit seamlessly with several engine models, ensuring optimal performance and durability. It is engineered to meet the stringent requirements of the engines it supports, providing reliable connections and preventing leaks.

Engine Compatibility

6C8.3 and K38 Engines

The Flexible Hose 3634470 is specifically tailored to fit the 6C8.3 and K38 engines. These engines benefit from the hose’s flexibility, which accommodates the natural movement and vibrations that occur during operation. The hose’s design ensures a secure and leak-proof connection, enhancing the overall efficiency and reliability of these engines.

K50 Engine

Similarly, the K50 engine is another beneficiary of the 3634470 Flexible Hose. Given the demanding nature of the K50 engine, the hose’s robust construction and flexibility are crucial. It provides a durable connection that can withstand the stresses of high-performance operations, ensuring that the engine runs smoothly and efficiently.

Key Features

- Flexibility: The hose’s flexibility allows it to adapt to the engine’s movements, reducing stress on the connections and preventing damage.

- Durability: Constructed from high-quality materials, the hose is built to last, providing long-term reliability and performance.

- Leak-Proof: The design of the hose ensures a secure fit, minimizing the risk of leaks and maintaining system integrity.

By integrating the Cummins part 3634470 Flexible Hose into the 6C8.3, K38, and K50 engines, users can expect improved performance, reduced maintenance needs, and enhanced operational efficiency.

Role of Part 3634470 Flexible Hose in Engine Systems

This part is integral to the efficient operation of various engine systems. It facilitates the secure and dynamic connection between the water outlet and other components, ensuring a reliable transfer of fluids under varying operational conditions.

Connection to Water Outlet

The flexible hose establishes a vital link between the water outlet and the engine’s water transfer connection. This connection allows for the smooth flow of coolant, which is essential for maintaining optimal engine temperature. The flexibility of the hose accommodates the natural movements and vibrations of the engine, preventing stress on the connection points and reducing the risk of leaks.

Integration with Hardware Kit

When paired with a hardware kit, the flexible hose enhances the overall robustness of the system. The hardware kit typically includes clamps, brackets, and other fastening components that secure the hose in place. This setup ensures that the hose remains firmly attached to the water outlet and other connections, even under the duress of engine vibrations and thermal expansion.

Role in Hose Vent and System Venting

The flexible hose also plays a part in the venting system of the engine. It connects to the hose vent, allowing any trapped air or gases within the coolant system to escape. This venting is important for preventing airlocks, which can impede the flow of coolant and lead to overheating. Additionally, the hose contributes to the overall venting system by providing a pathway for pressure relief, thus maintaining a stable operating environment within the engine compartment.

Engine Monitoring and Diagnostic Systems

In modern engine systems equipped with advanced monitoring capabilities, the flexible hose is often incorporated into the engine monitoring network. Sensors placed along the hose can detect changes in pressure, temperature, and flow rate. This data is crucial for the engine control unit (ECU) to make real-time adjustments, ensuring the engine operates within safe parameters. The hose’s flexibility allows it to be routed conveniently to these sensors without compromising the integrity of the connections.

Vent Hose Functionality

The flexible hose is also used in conjunction with the vent hose to manage the pressure within the cooling system. The vent hose allows excess pressure to be released, preventing buildup that could damage sensitive components. The flexible nature of the hose ensures that it can adapt to the layout of the engine bay, providing a reliable path for pressure relief without kinking or restriction.

Conclusion

In summary, the 3634470 Flexible Hose is a versatile component that enhances the functionality and reliability of engine systems by providing flexible, secure connections between critical components. Its integration into various engine models ensures optimal performance, reduced maintenance needs, and enhanced operational efficiency.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩

SPECIFICATIONS

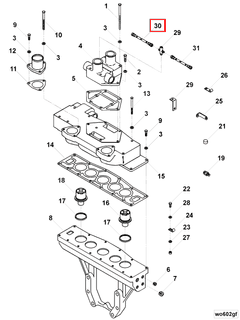

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.