This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3636395 Flexible Hose is a component designed for use in commercial truck operations. It serves as a conduit for various fluids within the truck’s systems, facilitating efficient and reliable operation. This part is integral to maintaining the functionality of critical systems by ensuring the smooth transfer of fluids under varying conditions.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and other systems to transfer fluids between different parts of a system. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses are typically made from materials that can withstand pressure, temperature variations, and chemical exposure. Their function is to provide a reliable connection that can flex and move with the components it connects, reducing the risk of leaks and system failures 1.

Purpose of the Cummins 3636395 Flexible Hose

The Cummins 3636395 Flexible Hose is specifically designed to connect various systems within a truck, transporting fluids such as coolant, fuel, or hydraulic fluid. It plays a role in ensuring that these fluids are delivered where needed without leakage or disruption, even as the truck undergoes the stresses of regular operation. This hose is part of the system that maintains the truck’s performance and efficiency 2.

Key Features

The Cummins 3636395 Flexible Hose boasts several features that enhance its performance. It is constructed from materials chosen for their flexibility, durability, and resistance to the specific fluids it transports. The hose’s design includes reinforced ends to ensure a secure connection to fittings, and its overall construction allows it to flex and move with the truck’s components, accommodating the dynamic environment in which it operates 3.

Benefits of Using the Cummins 3636395 Flexible Hose

Utilizing the Cummins 3636395 Flexible Hose offers several advantages. Its flexibility allows it to move with the truck’s components, reducing stress on connections and minimizing the risk of leaks. The hose’s durability ensures long-term reliability, even under harsh conditions. Additionally, its design contributes to the safety of the fluid transfer system by providing a secure and leak-resistant connection 4.

Installation Considerations

Proper installation of the Cummins 3636395 Flexible Hose is vital for its optimal performance and longevity. It is important to follow manufacturer guidelines for fitting connections to ensure they are secure and leak-free. The hose should be routed in a manner that avoids sharp bends or abrasion, which could compromise its integrity. Careful attention to these details during installation will help maintain the hose’s function and durability.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3636395 Flexible Hose involves inspecting it for signs of wear, such as cracks, bulges, or leaks. It is also important to check the connections for tightness and signs of corrosion. Troubleshooting common issues may involve identifying the source of a leak, assessing the hose for damage, and replacing it if necessary. Adhering to a maintenance schedule can help prevent unexpected failures and ensure the hose continues to perform reliably.

Common Applications

The Cummins 3636395 Flexible Hose finds application in various truck systems, including the cooling system for transferring coolant, the fuel system for delivering fuel, and hydraulic systems for moving hydraulic fluid. Its versatility makes it a valuable component in ensuring the efficient operation of these systems.

Safety Precautions

When handling, installing, or maintaining the Cummins 3636395 Flexible Hose, it is important to observe safety precautions to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following all manufacturer guidelines for installation and maintenance. These measures help ensure the safety of the person performing the work and the reliability of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Flexible Hose 3636395 Compatibility with QSK60 Engines

The Cummins Flexible Hose part number 3636395 is designed to integrate seamlessly with various QSK60 engine models. Specifically, it is compatible with the following engine configurations:

- QSK60 CM500

- QSK60 CM850 MCRS

This hose is engineered to provide a reliable connection between different engine components, ensuring optimal performance and durability. Its flexibility allows it to accommodate the dynamic movements and vibrations inherent in engine operations, reducing the risk of leaks and damage. The hose’s robust construction and precise fitment make it an essential component for maintaining the integrity of the engine’s fluid systems.

When installing the 3636395 Flexible Hose in the QSK60 CM500 and QSK60 CM850 MCRS engines, it is crucial to follow the manufacturer’s guidelines to ensure proper alignment and secure attachment. This will help maintain the engine’s efficiency and longevity, providing a dependable solution for both maintenance and operational needs.

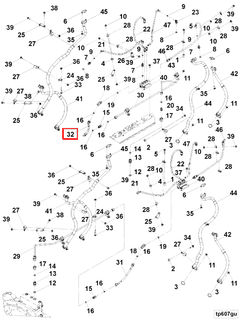

Role of Part 3636395 Flexible Hose in Engine Systems

Part 3636395 Flexible Hose is integral to the efficient operation of various engine systems, particularly in the context of plumbing and turbocharger applications.

Plumbing Systems

In plumbing systems, the Flexible Hose serves as a vital connector between different sections of the plumbing network. Its flexibility allows it to accommodate the vibrations and movements inherent in engine operations, ensuring a secure and leak-free connection. This is particularly important in high-pressure environments where rigid connections could lead to failures or leaks. The hose’s ability to flex and absorb movement helps maintain the integrity of the plumbing system, ensuring consistent fluid flow and pressure regulation.

Turbocharger Applications

When integrated into turbocharger systems, Part 3636395 Flexible Hose plays a significant role in managing the high-temperature and high-pressure conditions typical of turbocharger oil circuits. The hose’s flexibility is essential in connecting the turbocharger to the oil supply and return lines. This connection must withstand extreme conditions, including rapid temperature changes and high-pressure differentials. The Flexible Hose ensures that the oil supply remains uninterrupted, which is vital for the lubrication and cooling of turbocharger components. This, in turn, enhances the turbocharger’s efficiency and longevity.

Turbocharger Oil Circuits

In turbocharger oil circuits, the Flexible Hose is used to connect the turbocharger to the engine’s lubrication system. This connection is subjected to dynamic stresses due to engine vibrations and thermal expansion. The hose’s flexibility accommodates these stresses, preventing fatigue and potential failures. Additionally, it ensures a consistent oil flow to the turbocharger, which is essential for maintaining optimal performance and preventing overheating. The reliable connection provided by the Flexible Hose is key to the overall efficiency and durability of the turbocharger system.

Conclusion

The Cummins 3636395 Flexible Hose is a critical component in the operation of commercial trucks, providing a reliable and flexible solution for fluid transfer in various systems. Its design, compatibility with specific engine models, and role in enhancing engine performance make it an invaluable part of the truck’s infrastructure. Proper installation, maintenance, and adherence to safety precautions are essential to ensure the longevity and efficiency of this part.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.