3637767

Flexible Hose

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3637767 Flexible Hose is a component designed for use in commercial truck systems. It serves a specific function within the truck’s fluid transfer systems, facilitating the movement of various fluids essential for the truck’s operation.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and industrial systems to transfer fluids between different parts of a system. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses are typically made from materials that can withstand the pressure and temperature of the fluids they carry, as well as the environmental conditions they are exposed to 1.

Purpose of the Cummins 3637767 Flexible Hose

The Cummins 3637767 Flexible Hose is utilized in commercial trucks to connect various systems that require fluid transfer. It plays a role in transporting fluids such as coolant, fuel, or hydraulic fluid between components that may move relative to each other. This hose ensures a continuous and secure flow of fluids, which is vital for the proper functioning of the truck’s systems 2.

Key Features

The Cummins 3637767 Flexible Hose is characterized by its material composition, which typically includes synthetic rubber or other durable polymers. These materials are chosen for their flexibility, resistance to chemical degradation, and ability to withstand high pressures. The design of the hose may include reinforcement layers to enhance its durability and prevent kinking or collapse under pressure. Additionally, the hose is equipped with fittings that ensure a secure connection to the systems it serves 3.

Benefits

The Cummins 3637767 Flexible Hose offers several advantages. Its flexibility allows it to accommodate the movement and vibration inherent in truck operations without compromising the integrity of the fluid transfer. The material’s resistance to wear and tear contributes to the hose’s longevity, reducing the need for frequent replacements. Moreover, the design of the hose enhances safety and efficiency in fluid transfer, minimizing the risk of leaks and ensuring consistent performance.

Installation Considerations

When installing the Cummins 3637767 Flexible Hose, it is important to follow guidelines to ensure proper fitting and secure connections. The hose should be routed in a manner that avoids sharp bends or kinks, which could impede fluid flow or cause damage to the hose. Securement methods, such as clamps, should be used to fix the hose in place, ensuring it remains connected under all operating conditions. Compatibility with existing systems must be verified to prevent issues with fluid transfer.

Troubleshooting Common Issues

Common problems with flexible hoses include leaks, kinks, and degradation due to exposure to chemicals or environmental conditions. To address these issues, regular inspections should be conducted to identify signs of wear or damage. If a leak is detected, the source should be located and repaired or replaced as necessary. Kinks can often be resolved by rerouting the hose to avoid sharp bends. Degradation may require replacement of the hose to ensure safe and efficient fluid transfer.

Maintenance Tips

To ensure the longevity and reliable performance of the Cummins 3637767 Flexible Hose, regular maintenance practices should be followed. This includes periodic inspections to check for signs of wear, damage, or leaks. Replacement guidelines should be adhered to, with the hose being replaced at recommended intervals or when signs of significant degradation are observed. Proper storage and handling of the hose when not in use can also contribute to its longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

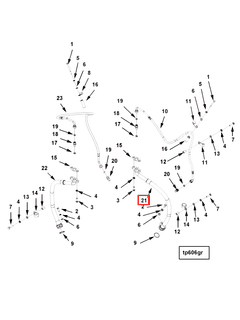

Role of Part 3637767 Flexible Hose in Engine Systems

Part 3637767 Flexible Hose is integral to the efficient operation of various engine systems. Its primary function is to facilitate the transfer of fluids and gases between different components while accommodating the dynamic movements and vibrations inherent in engine operation.

Oil Drain System

In the RB Turbo Oil Drain system, the Flexible Hose connects the turbocharger to the oil drainback system. This ensures that excess oil is efficiently returned to the sump, maintaining optimal lubrication levels and preventing oil starvation in the turbocharger bearings.

Manifold and Exhaust Systems

The Flexible Hose is employed in the manifold and exhaust systems to connect the turbocharger to the intake and exhaust manifolds. This allows for the smooth transfer of exhaust gases from the engine to the turbocharger, enhancing the efficiency of the exhaust gas recirculation (EGR) process. Additionally, it aids in reducing stress on the rigid piping by absorbing vibrations and thermal expansion.

Turbocharger Oil System

Within the Turbocharger Oil System, the Flexible Hose plays a key role in connecting the oil supply lines to the turbocharger. This ensures a consistent and reliable flow of oil to the turbocharger’s rotating components, which is essential for maintaining performance and longevity.

General Plumbing Applications

In general plumbing applications within the engine bay, the Flexible Hose is used to connect various fluid systems, such as coolant and fuel lines. Its flexibility allows for easier installation and maintenance, while its durability ensures long-term reliability in harsh operating conditions.

Conclusion

The Cummins 3637767 Flexible Hose is a vital component in commercial truck systems, designed to facilitate the efficient transfer of fluids and gases between various engine components. Its flexibility, durability, and resistance to wear and tear make it an essential part for maintaining the performance and reliability of commercial vehicles. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part in demanding operating conditions.

-

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.