This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

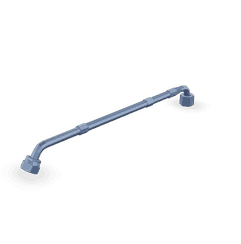

The Cummins 3638597 Flexible Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, facilitating the transfer of fluids or gases between various components. Cummins Inc., the manufacturer, is renowned in the industry for its commitment to quality and innovation, providing a wide range of products for automotive and industrial applications 1.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in both automotive and industrial settings to connect different parts of a system, allowing for the transfer of fluids or gases. They are constructed from materials that offer flexibility, durability, and resistance to the elements they transport. Common materials include rubber, plastic, and metal, each chosen for its specific properties such as flexibility, temperature resistance, and chemical compatibility 2.

Purpose of the 3638597 Flexible Hose in Truck Operations

This part plays a role in the truck’s system by connecting specific components and enabling the transport of fluids or gases. Its design allows for movement and vibration absorption, which are common in truck operations, ensuring a reliable connection between parts that may not be fixed in position.

Key Features of the 3638597 Flexible Hose

This Cummins part is characterized by its material composition, which includes a blend designed for durability and flexibility. It is engineered to withstand the pressures and temperatures associated with its application. Unique design elements may include reinforced sections for added strength or specialized fittings for secure connections.

Benefits of Using the 3638597 Flexible Hose

Incorporating this part into truck systems offers several advantages. These include improved system reliability due to its robust construction, ease of installation thanks to its flexible nature, and resistance to wear and tear from continuous use. Additionally, its design ensures compatibility with other components, facilitating a seamless integration into existing systems.

Installation Considerations

When installing the 3638597 Flexible Hose, it is important to follow guidelines to ensure proper function and longevity. This includes aligning the hose correctly with the components it connects, using appropriate securing methods to prevent disconnection, and verifying compatibility with the existing system to avoid issues.

Troubleshooting Common Issues

Common problems with flexible hoses, including the 3638597 model, may involve leaks, kinks, or reduced flexibility. A systematic approach to troubleshooting can help identify the root cause of these issues. This may involve inspecting the hose for physical damage, checking connections for proper alignment and security, and ensuring that the hose is not subjected to excessive pressure or temperature.

Maintenance Tips

To ensure the longevity and optimal performance of the 3638597 Flexible Hose, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, cleaning the hose to remove any buildup that could affect its function, and replacing the hose when it shows signs of significant degradation or when it reaches the end of its service life.

About Cummins

Cummins Inc. has a long-standing history in the automotive and industrial sectors, known for its extensive product range and dedication to quality and innovation. The company’s offerings span engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence is evident in its products, which are engineered to deliver reliable performance and durability 3.

Cummins Part 3638597: Flexible Hose Compatibility with Cummins Engines

The Cummins part 3638597, a Flexible Hose, is designed to integrate seamlessly with various Cummins engines, ensuring efficient fluid transfer and maintaining system integrity. This part is crucial for the operational efficiency of the engines, providing flexibility and durability in demanding environments.

K38 Engines

The K38 engine series by Cummins is known for its robust performance and reliability. The Flexible Hose part 3638597 is specifically engineered to fit these engines, ensuring smooth operation and reducing the risk of leaks or failures. Its design accommodates the unique layout and fluid pathways of the K38 engines, providing a reliable connection between various fluid systems.

Integration and Functionality

The Flexible Hose part 3638597 is integral to the K38 engines, connecting critical fluid systems such as the cooling, fuel, and lubrication systems. Its flexibility allows it to withstand the vibrations and movements inherent in engine operation, preventing wear and tear that could compromise system performance. This part is essential for maintaining the efficiency and longevity of the K38 engines, ensuring that all connected systems operate as intended.

Installation and Maintenance

Proper installation of the Flexible Hose part 3638597 is crucial for optimal engine performance. Technicians should ensure that the hose is correctly aligned with the engine’s fluid pathways and securely fastened to prevent any disconnections. Regular maintenance checks should be conducted to inspect the hose for signs of wear, cracks, or leaks, ensuring that it continues to provide a reliable connection throughout the engine’s operational life.

Role of Part 3638597 Flexible Hose in Engine Systems

Part 3638597 Flexible Hose is integral to the efficient operation of various engine systems. It facilitates the transfer of fluids, gases, and other substances between different components, ensuring seamless functionality.

Fuel System Integration

In the fuel system, the flexible hose connects the fuel tank to the fuel pump and subsequently to the engine. This connection allows for the smooth flow of fuel, accommodating the dynamic movements and vibrations of the engine without compromising the integrity of the fuel line.

Cooling System Functionality

Within the cooling system, the flexible hose plays a significant role by linking the radiator to the engine block and water pump. This setup enables the circulation of coolant, which is essential for maintaining optimal engine temperature. The flexibility of the hose absorbs vibrations and movements, preventing stress on the connections and reducing the risk of leaks.

Emission Control System

In the emission control system, the flexible hose is used to connect various components such as the catalytic converter, oxygen sensors, and the exhaust manifold. This ensures that exhaust gases are efficiently routed through the system, allowing for effective monitoring and reduction of harmful emissions.

Brake System Application

For the brake system, the flexible hose is employed to connect the brake fluid reservoir to the brake lines. This connection ensures that brake fluid is delivered consistently to the brake calipers and wheel cylinders, enhancing braking performance and safety.

Auxiliary Systems

Beyond the primary systems, the flexible hose is also utilized in auxiliary systems such as the power steering system. Here, it connects the power steering pump to the steering gear, ensuring that hydraulic fluid is efficiently transferred to assist in steering operations.

General Usage

Across these applications, the flexible hose’s ability to withstand high pressures, temperatures, and chemical exposures makes it a reliable component. Its flexibility also allows for easier installation and maintenance, reducing the complexity of engine system repairs and upgrades.

Conclusion

The Cummins 3638597 Flexible Hose is a vital component in commercial truck systems, offering durability, flexibility, and reliable performance. Its integration into various engine systems ensures efficient fluid transfer and maintains system integrity. Proper installation, regular maintenance, and timely replacement are key to maximizing its benefits and ensuring the longevity of the truck’s operational efficiency.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.