This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3639614 Molded Hose Assembly by Cummins is a specialized component designed for use in commercial trucks. This assembly is integral to the efficient operation of the truck’s systems, ensuring that fluids are transported reliably and efficiently throughout the vehicle. Its role is significant in maintaining the overall performance and reliability of commercial trucks, particularly in demanding operational environments.

Basic Concepts of Molded Hose Assembly

A Molded Hose Assembly is a pre-formed hose that is custom-designed to fit specific applications within a vehicle’s system. It is constructed from durable materials that can withstand high pressure and temperature variations. The assembly typically includes reinforced ends for secure attachment to fittings and is designed to reduce the risk of leaks and failures. Within a truck’s system, it facilitates the transfer of fluids such as coolant, fuel, or hydraulic fluid, contributing to the smooth operation of various subsystems 1.

Purpose of the 3639614 Molded Hose Assembly

This Cummins part is designed to play a specific role in the operation of a truck. It is used to connect different components within the truck’s fluid systems, ensuring that fluids are delivered where needed without leakage or loss of pressure. This assembly is particularly important in applications where space is limited, or where the hose must navigate around other components. Its design allows for a more streamlined installation process and reduces the potential for human error during assembly 2.

Key Features

The 3639614 Molded Hose Assembly boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to abrasion, chemicals, and extreme temperatures. The design includes precise fittings that ensure a secure connection, minimizing the risk of disconnection or leakage. Additionally, the assembly may feature unique characteristics such as integrated sensors for monitoring fluid flow or pressure, contributing to the overall efficiency and safety of the truck’s operation 3.

Benefits

The use of the 3639614 Molded Hose Assembly provides several benefits to truck operations. Its robust construction and precise design contribute to improved performance by ensuring reliable fluid transfer. The assembly’s durability reduces the need for frequent replacements, leading to cost savings over time. Furthermore, its reliable operation enhances the overall reliability of the truck, minimizing downtime and contributing to a safer driving experience 4.

Installation Process

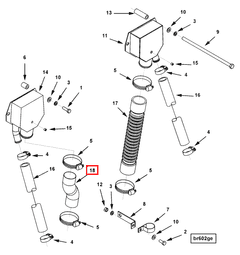

Installing the 3639614 Molded Hose Assembly requires careful attention to detail to ensure proper function and longevity. The process involves identifying the correct location for the assembly within the truck’s system, ensuring that all connections are secure and that the assembly is properly aligned. Tools such as wrenches and possibly a torque wrench may be required to tighten fittings to the manufacturer’s specifications. It is important to follow the installation instructions provided by Cummins to ensure the assembly is installed correctly.

Common Issues and Troubleshooting

Common issues with the 3639614 Molded Hose Assembly may include leaks, disconnections, or damage to the hose itself. Troubleshooting these issues involves inspecting the assembly for signs of wear or damage, ensuring that all connections are secure, and checking for proper alignment within the system. If a leak is detected, it may be necessary to replace the affected section of the hose or the entire assembly, depending on the severity of the issue.

Maintenance Tips

Regular maintenance of the 3639614 Molded Hose Assembly is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, damage, or leaks. It is also important to ensure that all connections remain secure and that the assembly is properly aligned within the system. Following the manufacturer’s recommendations for maintenance intervals and procedures will help to prevent issues and ensure the assembly continues to function effectively.

Compatibility and Applications

The 3639614 Molded Hose Assembly is designed for use in specific types of trucks and engine models. Its compatibility ensures that it fits precisely within the intended application, contributing to the efficient operation of the truck’s systems. Detailed information on compatibility and applications is available from Cummins, ensuring that the assembly is used in the correct context.

Cummins: A Brief Overview

Cummins is a well-established manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and commitment to excellence, Cummins has built a reputation for reliability and performance. The company’s product range includes engines, powertrains, and various components designed to enhance the efficiency and reliability of commercial trucks. Cummins’ expertise and dedication to quality make it a trusted name in the industry.

Cummins Molded Hose Assembly Part 3639614 in QSK38 Engines

The Cummins Molded Hose Assembly part number 3639614 is a critical component in the QSK38 series engines, specifically the QSK38 CM2150 MCRS and QSK38 CM850 MCRS models. This hose assembly is designed to ensure efficient fluid transfer within the engine’s cooling and lubrication systems.

In the QSK38 CM2150 MCRS engine, the molded hose assembly connects various fluid pathways, ensuring that coolant and lubrication fluids are delivered to their respective destinations without leaks or blockages. This is crucial for maintaining optimal engine performance and longevity.

Similarly, in the QSK38 CM850 MCRS engine, the part 3639614 serves the same purpose. It is engineered to withstand the high pressures and temperatures typical of these engines, providing a reliable conduit for essential fluids. The hose’s durability and flexibility make it an ideal choice for the demanding environments within these engines.

Both engines benefit from this hose assembly’s precision fit and robust construction, ensuring that fluid flow is maintained consistently, which is vital for the engines’ overall efficiency and reliability.

Conclusion

The 3639614 Molded Hose Assembly is integral to the efficient operation of the breather and crankcase systems in an engine. In the breather system, this hose assembly facilitates the controlled release of gases and vapors from the crankcase. It ensures that these byproducts are vented safely and efficiently, maintaining the integrity of the engine’s internal environment. The assembly is designed to withstand the pressures and temperatures associated with these emissions, ensuring reliable performance over time.

Regarding the crankcase, the hose assembly plays a key role in managing the circulation of gases within the system. It connects various components, allowing for the smooth transfer of gases from the crankcase to other parts of the engine where they can be processed or expelled. This helps in maintaining optimal pressure levels within the crankcase, which is essential for the proper functioning of the engine’s moving parts.

The assembly’s design also contributes to reducing emissions, as it ensures that gases are directed to the appropriate systems for treatment before being released into the atmosphere. This not only enhances the engine’s efficiency but also ensures compliance with environmental regulations.

In summary, the 3639614 Molded Hose Assembly is a vital component in the breather and crankcase systems, ensuring efficient gas management and contributing to the overall performance and environmental compliance of the engine.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.