This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

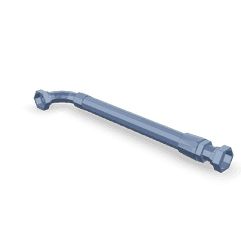

The Cummins 3639985 Flexible Hose is a specialized component designed for commercial trucks, ensuring the efficient and reliable operation of critical fluid transport systems within these vehicles.

Basic Concepts of Flexible Hoses

Flexible hoses are integral to automotive applications, connecting system components that may move or vibrate relative to each other. They are engineered to withstand pressure, temperature variations, and mechanical stress while accommodating movement. These hoses facilitate the transfer of fluids such as coolant, fuel, or hydraulic fluid, essential for the dynamic nature of vehicle operation 1.

Purpose of the Cummins 3639985 Flexible Hose

This Cummins part is engineered to connect components within a truck’s system, transporting essential fluids. It maintains the integrity of fluid pathways, ensuring fluids reach their destinations without leakage or disruption.

Key Features

The 3639985 Flexible Hose is characterized by its reinforced synthetic rubber composition, providing durability and flexibility. Its design includes braided reinforcement for enhanced strength and abrasion resistance, enabling it to perform under demanding commercial truck conditions 2.

Benefits

This part offers enhanced flexibility, accommodating movement and vibration inherent in truck operations. Its resistance to wear and tear ensures a longer service life, contributing to the overall efficiency and reliability of the truck’s systems.

Installation Considerations

Proper installation of the 3639985 Flexible Hose is crucial. Preparatory steps include cleaning connection points and inspecting the hose for damage. Tools such as hose clamps and wrenches are required. Avoid over-tightening clamps and ensure proper alignment to prevent leaks 3.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, cracks, or kinks, often due to wear and tear, improper installation, or extreme conditions. Solutions may involve replacing the hose, ensuring proper clamp torque, or rerouting the hose to avoid sharp bends.

Maintenance Tips

Regular maintenance of the 3639985 Flexible Hose includes inspection routines for signs of wear, such as cracking or bulging, and ensuring secure connections. Replace the hose if it shows significant wear or has been in service for an extended period, even without visible damage.

Safety Precautions

When handling the 3639985 Flexible Hose, observe safety measures such as wearing protective equipment to guard against fluid exposure and potential injury. Handle the hose carefully to avoid damage. Have emergency response protocols in place for fluid leaks, which can pose slipping hazards or environmental concerns.

Cummins Overview

Cummins Inc. is renowned for its diesel engines, related technologies, and services. With a history of several decades, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet various applications, from on-highway to off-highway and power generation.

Role of the 3639985 Flexible Hose in Engine Systems

The 3639985 Flexible Hose is integral to various engine systems, facilitating efficient fluid transfer while accommodating engine movements and vibrations.

- Fuel Systems: Connects the fuel tank to the fuel pump and engine’s fuel injectors, ensuring consistent fuel flow and engine performance.

- Plumbing Systems: Connects components like the radiator to the engine block and water pump, vital for coolant circulation and engine temperature regulation.

- Fuel Filter Systems: Connects the filter to fuel lines, ensuring efficient fuel filtration and maintaining a clean fuel supply.

Conclusion

The Cummins 3639985 Flexible Hose enhances the reliability and performance of engine systems by providing a durable, flexible connection that withstands the rigors of engine operation. Proper installation, maintenance, and safety precautions are essential for its effective use in commercial trucks.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.