This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

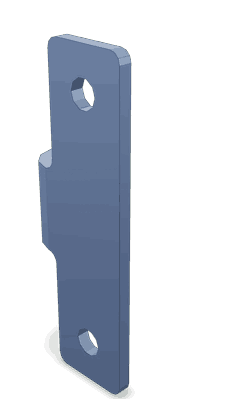

The Cummins 3642800 Hose Brace is a component designed to support and secure hoses within the systems of commercial trucks. Its role is to maintain the integrity and efficiency of the hoses by keeping them in the correct position and protecting them from potential damage caused by vibrations or movement 1.

Basic Concepts of Hose Braces

A hose brace is a support structure that holds hoses in place within a vehicle’s system. It functions by providing a stable mounting point for hoses, which helps to prevent them from shifting or rubbing against other components. This stability is essential for maintaining the efficiency of fluid transfer systems and ensuring that hoses remain undamaged over time 2.

Purpose of the Cummins 3642800 Hose Brace

The Cummins 3642800 Hose Brace is specifically designed to secure hoses in their designated positions within the truck’s system. This helps to prevent hoses from coming into contact with moving parts or sharp edges, which could lead to wear, leaks, or complete failure. By maintaining the hoses in their intended configuration, the brace contributes to the overall reliability and performance of the truck’s systems 3.

Key Features

The Cummins 3642800 Hose Brace is constructed from durable materials that are resistant to the harsh conditions found in commercial truck environments. Its design includes features that allow for easy installation and adjustment, ensuring that hoses are held securely without excessive tension. Additionally, the brace may incorporate elements that protect the hose from abrasion and environmental factors, enhancing its longevity and performance 4.

Benefits of Using the Cummins 3642800 Hose Brace

Utilizing the Cummins 3642800 Hose Brace can lead to improved hose longevity, as it reduces the risk of damage from movement and vibration. This, in turn, can enhance the reliability of the truck’s systems, leading to fewer breakdowns and interruptions in service. Moreover, by preventing hose damage, the brace can contribute to cost savings through reduced maintenance needs and extended hose life 1.

Installation Considerations

When installing the Cummins 3642800 Hose Brace, it is important to follow guidelines and best practices to ensure optimal performance. This includes preparing the installation site, using the appropriate tools, and carefully aligning the brace with the hose and mounting points. Proper installation is key to achieving the intended benefits of the hose brace 2.

Troubleshooting Common Issues

Common problems associated with hose braces can include improper alignment, which may lead to hose stress or damage, and failure to secure the hose adequately, resulting in movement and potential wear. Troubleshooting these issues involves checking the alignment and tension of the brace, ensuring that it is correctly installed, and making adjustments as necessary to resolve any problems 3.

Maintenance Tips

Regular maintenance of the Cummins 3642800 Hose Brace involves inspection routines to check for signs of wear, damage, or misalignment. Cleaning the brace and surrounding areas can help prevent buildup that might affect performance. If significant wear or damage is observed, considering replacement of the brace may be necessary to maintain system integrity and performance 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a strong reputation in the commercial truck industry, Cummins products are known for their quality, reliability, and performance. The 3642800 Hose Brace is part of Cummins’ commitment to providing durable and efficient components for the commercial vehicle market 1.

Role of Part 3642800 Hose Brace in Engine Systems

The part 3642800 Hose Brace is instrumental in maintaining the structural integrity and efficient operation of various engine components. Specifically, it plays a significant role in the setup and functionality of the Pump and Fuel Transfer systems.

Integration with the Pump System

In the Pump system, the Hose Brace ensures that the hoses remain securely in place, minimizing the risk of disconnection or leakage. This stability is essential for consistent pump performance, as it allows for uninterrupted fluid flow. The secure attachment provided by the Hose Brace helps in maintaining the optimal pressure levels required for efficient pumping operations 2.

Contribution to the Fuel Transfer System

Within the Fuel Transfer system, the Hose Brace is equally important. It supports the hoses that carry fuel from the storage tanks to the engine, ensuring a steady and reliable fuel supply. The brace prevents hose movement and potential wear, which could otherwise lead to fuel leaks or inefficient fuel delivery. This reliability is key to the overall performance and safety of the engine system 3.

Conclusion

By providing a stable and secure environment for the hoses in both the Pump and Fuel Transfer systems, the part 3642800 Hose Brace contributes significantly to the operational efficiency and safety of the engine. Its durable construction, ease of installation, and compatibility with various engine models make it a valuable component in maintaining the reliability and performance of commercial truck systems 4.

-

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Routledge, 2023.

↩ ↩ ↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ ↩ ↩ -

Tom Denton and Hayley Pells, Automotive Technician Training, Second Edition, Routledge, 2022.

↩ ↩ ↩ -

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.