3643999

Molded Hose

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3643999 Molded Hose is a specialized component designed for use in commercial trucks. It plays a role in ensuring the efficient operation of various truck systems by facilitating the transfer of fluids. Understanding its purpose and functionality is key to maintaining the overall performance and reliability of commercial vehicles.

Basic Concepts of Molded Hoses

Molded hoses are manufactured through a process that involves molding synthetic rubber or thermoplastic materials around embedded textile or wire reinforcements. This construction method provides molded hoses with enhanced flexibility, durability, and resistance to various environmental factors. In automotive systems, molded hoses are commonly used to transport fluids such as coolant, fuel, and hydraulic fluid, connecting different components within the vehicle 1.

Purpose of the 3643999 Molded Hose

The Cummins 3643999 Molded Hose is specifically designed to play a role in the fluid transfer systems of trucks. It connects critical components, ensuring the smooth and efficient transport of fluids necessary for the operation of the vehicle. This hose is integral to maintaining the functionality of systems it is a part of, contributing to the overall performance and reliability of the truck.

Key Features

The Cummins 3643999 Molded Hose is characterized by its robust design and construction. It is made from high-quality materials that offer resistance to wear, abrasion, and environmental factors. The hose features secure connection types that ensure a tight fit and reliable fluid transfer. Its unique attributes, such as reinforced layers and precise molding, enhance its performance and durability in demanding conditions.

Benefits

Utilizing the Cummins 3643999 Molded Hose offers several advantages. Its design contributes to improved reliability in fluid transfer systems, reducing the likelihood of leaks and failures. The hose’s resistance to wear and tear ensures longevity, even under challenging operating conditions. Additionally, its enhanced performance supports the efficient operation of the truck’s systems.

Installation Considerations

When installing the Cummins 3643999 Molded Hose, it is important to follow guidelines and best practices to ensure proper fit and function. Preparation steps include cleaning the installation area and inspecting the hose for any damage. Tools required may vary, but typically include wrenches for securing connections. Common pitfalls to avoid during installation include over-tightening connections and not ensuring a proper seal, which can lead to leaks or inefficient fluid transfer.

Troubleshooting Common Issues

Typical problems that may arise with the Cummins 3643999 Molded Hose include leaks or blockages. Diagnosing these issues involves inspecting the hose for signs of wear, damage, or improper installation. Resolving these issues may require repairing or replacing the hose, ensuring all connections are secure and properly sealed.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3643999 Molded Hose. This includes periodic inspection for signs of wear or damage, cleaning the hose and its connections, and ensuring all fittings remain secure. Adhering to these maintenance tips can help prevent issues and extend the service life of the hose.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance components that contribute to the efficiency and durability of commercial vehicles.

Cummins Molded Hose Part 3643999 in Engine Applications

The Cummins molded hose part number 3643999 is a component in various engine systems, ensuring the seamless transfer of fluids and gases. This hose is engineered to withstand the demanding conditions of engine environments, providing durability and reliability.

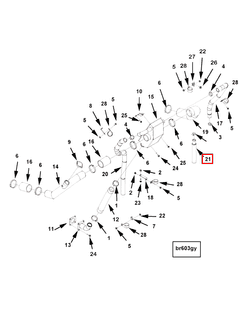

QSK60 Engine Group

In the QSK60 engine series, the molded hose part 3643999 plays a role in maintaining the integrity of the engine’s fluid systems. It is often utilized in applications where precise fluid management is essential, such as in the cooling system or fuel delivery system. The hose’s design allows it to connect various engine components, ensuring that fluids are transported efficiently and safely.

CM500 Engine Group

Similarly, in the CM500 engine series, the molded hose part 3643999 is integral to the engine’s operational efficiency. This hose is typically used in applications that require robust fluid transfer, such as in the lubrication system or exhaust recirculation system. Its construction ensures that it can endure the high temperatures and pressures commonly found in these systems, contributing to the overall performance and longevity of the engine.

Common Features and Benefits

- Durability: The hose is made from high-quality materials that resist wear and tear, ensuring a long service life.

- Compatibility: Designed to fit seamlessly with other components in the engine system, facilitating easy installation and maintenance.

- Performance: Enhances the efficiency of fluid transfer, contributing to the overall performance of the engine.

- Reliability: Built to withstand the harsh conditions of engine environments, providing consistent performance over time.

By integrating the molded hose part 3643999 into their systems, the QSK60 and CM500 engines benefit from improved fluid management, which is crucial for maintaining optimal engine performance and longevity.

Role of Part 3643999 Molded Hose in Engine Systems

The part 3643999 molded hose is a component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth transfer of fluids and gases between different parts of the engine, ensuring optimal performance and reliability.

Breather System Integration

In the breather system, the molded hose plays a role by connecting the crankcase to the air intake system. This connection allows for the release of pressure built up within the crankcase, which is vital for maintaining a stable environment for the engine’s moving parts. The molded hose ensures that any excess gases are directed away from the crankcase, preventing contamination and ensuring that the breather system operates efficiently. This, in turn, helps in reducing the risk of oil leaks and maintaining the integrity of the engine’s lubrication system.

Crankcase Ventilation

The crankcase ventilation system relies on the molded hose to manage the flow of gases produced during the combustion process. By connecting the crankcase to the intake manifold, the hose allows these gases to be recirculated back into the engine, where they can be burned again. This not only improves fuel efficiency but also reduces emissions, contributing to a cleaner and more environmentally friendly operation. The molded hose’s durable construction ensures that it can withstand the high temperatures and pressures associated with crankcase ventilation, providing a reliable solution for this critical function.

Enhanced Engine Performance

By integrating the molded hose into these systems, engineers and mechanics can ensure that the engine operates at peak efficiency. The hose’s ability to handle various fluids and gases under different conditions makes it an invaluable component in maintaining the overall health and performance of the engine. Its role in facilitating the proper function of the breather and crankcase ventilation systems underscores its importance in the broader context of engine maintenance and optimization.

Conclusion

The Cummins 3643999 Molded Hose is a vital component in the fluid transfer systems of commercial trucks and engines. Its robust design, durability, and reliable performance contribute to the efficient operation and longevity of the vehicles it serves. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its benefits and ensuring the optimal performance of commercial trucks and engines.

-

Wilfried J Bartz, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.