This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

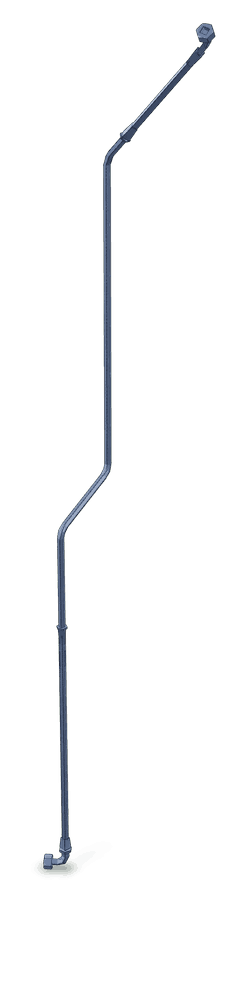

The Cummins 3644865 Flexible Hose is a component designed for use in commercial truck systems. Its purpose is to facilitate the transfer of fluids between various parts of the truck’s system, accommodating movement and vibration that rigid hoses cannot. This flexibility helps maintain a secure and efficient fluid transfer system within the truck 2.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without compromising their integrity. They are commonly used in automotive and truck systems to connect components that may move relative to each other. Flexible hoses function by providing a pathway for fluids such as coolant, fuel, or hydraulic fluid to flow between parts of the system, while also absorbing vibrations and movements that could otherwise cause damage or leaks in a rigid hose 1.

Purpose of the Cummins 3644865 Flexible Hose

The Cummins 3644865 Flexible Hose serves a specific role in the operation of a truck. It connects various systems within the truck, allowing for the transport of fluids such as coolant or hydraulic fluid. By providing a flexible connection, it ensures that the flow of these fluids is not interrupted by the natural movements and vibrations of the truck during operation 3.

Key Features

The Cummins 3644865 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include its material composition, which is designed to withstand the pressures and temperatures of the fluids it transports. Its flexibility allows it to accommodate the movements of the truck’s components, while its durability ensures long-term reliability. The hose is also designed with specific specifications to meet the demands of commercial truck applications 4.

Benefits

Using the Cummins 3644865 Flexible Hose offers several benefits. Its improved flexibility over rigid hoses allows for better accommodation of the movements within the truck’s system. This reduces the risk of leaks that can occur with rigid connections. Additionally, the hose’s enhanced durability contributes to its longevity, and its design makes it easier to install compared to rigid hoses, saving time and effort during maintenance or replacement 2.

Installation Considerations

Proper installation of the Cummins 3644865 Flexible Hose is important for ensuring optimal performance and longevity. Techniques include careful routing of the hose to avoid sharp bends or kinks, securing it in place to prevent movement that could lead to wear or damage, and avoiding common pitfalls such as over-tightening connections, which can cause premature failure 4.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. Troubleshooting steps may involve inspecting the hose for signs of wear or damage, ensuring connections are secure but not over-tightened, and replacing the hose if it shows signs of significant degradation or if leaks cannot be stopped 1.

Maintenance Tips

Regular maintenance practices can prolong the life of the Cummins 3644865 Flexible Hose. This includes inspecting the hose for signs of wear, checking connections for leaks, and cleaning the hose as necessary. Replacement should be considered if the hose shows significant signs of degradation or if leaks persist despite attempts to repair them 3.

Compatibility and Applications

The Cummins 3644865 Flexible Hose is designed for use in various truck systems, with applications that may vary depending on the specific model and make of the truck. Compatibility with other components is an important consideration, ensuring that the hose fits properly and functions as intended within the system 4.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products including engines, filtration systems, and components like the Cummins 3644865 Flexible Hose. With a history of innovation and a strong reputation for quality, Cummins continues to be a trusted name in the industry, providing reliable solutions for commercial truck applications 2.

Cummins Engine Part 3644865: Flexible Hose Compatibility

The Cummins part number 3644865, a Flexible Hose, is designed to fit seamlessly within the engine systems of the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. This part is integral to the engine’s operation, ensuring that fluid transfer between various components occurs efficiently and without leaks 4.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

Both the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines benefit from the use of the Flexible Hose part 3644865. This hose is engineered to withstand the high pressures and temperatures typical of these engines, providing a reliable connection that is crucial for the engine’s performance and longevity 4.

The Flexible Hose part 3644865 is designed to connect various fluid systems within the engine, ensuring that the fluid transfer is smooth and uninterrupted. This is particularly important in high-performance engines like the QSK50 series, where precise fluid management is essential for optimal operation 4.

In both engines, the hose is strategically placed to handle the transfer of fluids such as coolant, oil, and other essential liquids. Its flexibility allows it to accommodate the engine’s movements and vibrations, reducing the risk of wear and tear that could lead to leaks or failures 4.

By integrating the Flexible Hose part 3644865 into the engine systems, Cummins ensures that these engines maintain their efficiency and reliability, providing the power and performance that users expect from high-quality industrial engines 4.

Role of Part 3644865 Flexible Hose in Plumbing and Turbocharger Coolant Systems

Plumbing Systems

In plumbing systems, the flexible hose component, part 3644865, is instrumental in connecting various sections of the plumbing network. Its flexibility allows for the accommodation of slight misalignments between pipes, which is common in installations where precision alignment is challenging. This flexibility reduces the stress on the connections, thereby minimizing the risk of leaks and the need for frequent repairs. Additionally, the hose’s material is typically resistant to corrosion and high temperatures, ensuring durability in various plumbing environments. The hose facilitates easier installation and maintenance, as it can be easily cut to size and connected using standard fittings 3.

Turbocharger Coolant Systems

In turbocharger coolant systems, part 3644865 flexible hose plays a significant role in maintaining the efficiency and longevity of the turbocharger. The hose is used to connect the turbocharger to the engine’s coolant system, allowing for the circulation of coolant to regulate the turbocharger’s temperature. The flexibility of the hose is particularly beneficial in this application, as it can withstand the vibrations and movements associated with the operation of the turbocharger. This reduces the likelihood of hose failure due to fatigue. Furthermore, the hose is designed to handle the high pressures and temperatures present in the coolant system, ensuring reliable performance and protection of the turbocharger from overheating. The use of a flexible hose also simplifies the routing of coolant lines, allowing for more efficient and compact designs in the engine bay 4.

Conclusion

The Cummins 3644865 Flexible Hose is a vital component in commercial truck systems, offering flexibility, durability, and ease of installation. Its role in facilitating fluid transfer, accommodating movement and vibration, and ensuring system efficiency makes it an essential part of modern truck technology. Proper installation, maintenance, and understanding of its applications are key to maximizing the benefits of this Cummins part.

-

Matthew Huang, Vehicle Crash Dynamics, CRC Press, 2002.

↩ ↩ -

Joseph A Bell, Modern Diesel Technology Electricity Electronics, Delmar Cengage Learning, 2014.

↩ ↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ ↩ ↩ -

QSK95 CM2350 K128M, Service Manual (5411387).

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.