This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

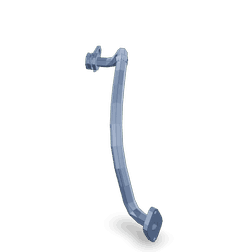

The Cummins 3648009 Flexible Hose is a critical component in commercial truck systems, designed to facilitate efficient and reliable fluid transfer. Understanding its function and role is essential for maintaining and optimizing truck performance.

Basic Concepts of Flexible Hoses

Flexible hoses are integral to various automotive and industrial applications, designed to transfer fluids between system components. They accommodate movement and vibration, reducing stress on connected parts compared to rigid pipes 1. In automotive systems, these hoses are commonly used for fuel, coolant, brake fluid, and other vital fluids.

Purpose of the 3648009 Flexible Hose

The Cummins 3648009 Flexible Hose is used in commercial trucks to connect systems requiring fluid transfer. It ensures efficient operation by transporting fluids like coolant or fuel, connecting various engine and fluid system parts, and facilitating fluid flow despite vibrations and movements 2.

Key Features

This Cummins part features a durable material composition resistant to various fluids, flexibility to accommodate movement, and design specifications for a secure fit and efficient fluid transfer. It is engineered to withstand the demanding conditions of commercial truck environments 3.

Benefits

Using the 3648009 Flexible Hose offers advantages such as flexibility to accommodate movement and vibration without compromising fluid transfer system integrity. Its durability ensures resistance to wear and tear, enhancing the safety and efficiency of the truck’s fluid systems. The hose’s design also reduces the risk of leaks and system failures 4.

Installation Considerations

Proper installation of the 3648009 Flexible Hose is crucial for its performance and longevity. This includes verifying compatibility with existing systems, using appropriate fitting methods, and ensuring the hose is correctly positioned to accommodate the truck’s movements and vibrations.

Troubleshooting Common Issues

Common issues with flexible hoses, such as leaks, kinks, or degradation, can arise from wear and tear, improper installation, or harsh conditions. Troubleshooting involves inspecting the hose for damage, ensuring proper fitting and securement, and addressing underlying causes of wear or degradation. Regular checks can help identify and resolve issues before they lead to system failures.

Maintenance Tips

Regular maintenance is vital for the longevity and reliable performance of the 3648009 Flexible Hose. This includes inspecting the hose for wear or damage, checking for proper fitting and securement, and replacing the hose according to manufacturer guidelines or when signs of degradation are observed. Adhering to a maintenance schedule helps prevent unexpected failures and ensures efficient operation of the truck’s fluid systems.

Safety Precautions

When working with the 3648009 Flexible Hose, observing safety measures is crucial. This includes proper handling to avoid damage, avoiding overtightening during installation to prevent stress on the hose, and recognizing signs of potential failure such as leaks or unusual wear. Safety precautions ensure the safe and efficient operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry for quality, reliability, and performance. The company’s commitment to excellence is reflected in its products, including the Cummins 3648009 Flexible Hose.

Role of Part 3648009 Flexible Hose in Plumbing and Turbocharger Oil Systems

Plumbing Systems

In plumbing systems, the 3648009 Flexible Hose is used to connect various components, ensuring a secure and leak-free connection. Its flexibility accommodates movements and vibrations within plumbing setups, reducing the risk of stress-related failures. This hose is often employed to link pipes, valves, and fixtures, facilitating the smooth flow of fluids while withstanding pressure fluctuations and temperature variations. Its application in plumbing ensures durability and reliability, contributing to the overall efficiency of the system.

Turbocharger Oil Systems

Within turbocharger oil systems, the 3648009 Flexible Hose maintains the integrity of oil circulation by connecting the turbocharger to the oil supply and return lines. This allows for consistent lubrication of moving parts. The hose’s flexibility is essential in managing the dynamic environment of a turbocharger, where components undergo rapid acceleration and deceleration. By providing a robust yet adaptable connection, it helps prevent oil leaks and ensures the turbocharger receives the necessary lubrication to operate efficiently and prolong its service life.

Conclusion

The Cummins 3648009 Flexible Hose plays a vital role in the efficient and reliable operation of commercial truck systems. Its design, featuring durability, flexibility, and secure fitting, ensures optimal fluid transfer across various engine models and systems. Regular maintenance, proper installation, and adherence to safety precautions are essential for maximizing the performance and longevity of this part. Cummins’ commitment to quality and innovation is evident in the 3648009 Flexible Hose, making it a reliable component in the demanding environments of commercial trucking.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.