This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

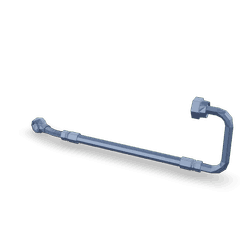

The Cummins 3651721 Flexible Hose is a specialized component designed for use in commercial truck systems. It serves as a vital link in various fluid transport systems within these vehicles, ensuring efficient and reliable operation. This hose is engineered to withstand the demanding conditions encountered in commercial trucking, providing a flexible yet durable solution for connecting different parts of the truck’s fluid systems.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and industrial applications to transport fluids between different parts of a system. Unlike rigid pipes, flexible hoses can bend and move with the system, accommodating vibrations, thermal expansion, and other dynamic movements. They are typically made from a combination of rubber, synthetic materials, and reinforcing fibers to balance flexibility with strength. In automotive systems, flexible hoses are used for fuel lines, coolant systems, brake lines, and more, providing a reliable means of fluid transport that can adapt to the movement and stress of the vehicle 1.

Purpose of the Cummins 3651721 Flexible Hose

The Cummins 3651721 Flexible Hose plays a specific role in the operation of commercial trucks by connecting various fluid systems. It is designed to transport fluids such as coolant, fuel, or hydraulic fluid between components that may move relative to each other. This hose ensures a continuous and leak-free flow of fluids, which is crucial for the proper functioning of the truck’s engine, cooling system, or hydraulic systems. Its flexibility allows it to accommodate the movement and vibration inherent in truck operations, maintaining system integrity and performance 2.

Key Features

The Cummins 3651721 Flexible Hose is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that offer excellent resistance to wear, abrasion, and chemical degradation. The hose’s flexibility is achieved through a combination of synthetic rubber and reinforcing fibers, allowing it to bend and twist without compromising its structural integrity. Additionally, the hose is designed with precision-engineered fittings that ensure a secure and leak-free connection to the systems it serves. These features contribute to the hose’s reliability and longevity in demanding commercial truck applications 3.

Benefits

Using the Cummins 3651721 Flexible Hose offers several advantages over traditional rigid hoses. Its flexibility reduces the risk of leaks by accommodating the natural movements and vibrations of the truck’s components. This results in improved system reliability and reduced maintenance needs. The hose’s durable construction ensures long-lasting performance, even under harsh operating conditions. Furthermore, the ease of installation and maintenance of flexible hoses can lead to cost savings and increased uptime for commercial fleets.

Installation Considerations

When installing the Cummins 3651721 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the correct fittings and securing methods to prevent leaks and ensure a tight connection. Careful alignment of the hose within the truck’s system is also crucial to avoid kinks or unnecessary stress on the hose. Proper installation techniques, such as using appropriate clamps and ensuring the hose is not over-tightened, are essential for maintaining the integrity of the fluid transport system.

Troubleshooting Common Issues

Common issues associated with flexible hoses include leaks, kinks, and degradation over time. To address these problems effectively, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the connection points should be checked for proper tightness, and any damaged sections of the hose should be replaced. Kinks can often be resolved by rerouting the hose to avoid sharp bends. Degradation may require replacement of the hose, especially if it shows signs of cracking or significant wear.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3651721 Flexible Hose, regular maintenance is recommended. This includes routine inspections for signs of wear, leaks, or damage. Cleaning the hose and its connections can prevent the buildup of contaminants that may accelerate degradation. Additionally, monitoring the hose for any changes in flexibility or appearance can help identify potential issues before they lead to system failure. When replacing the hose, it is important to use genuine Cummins parts to maintain system compatibility and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Understanding the Role of Part 3651721 Flexible Hose in Engine Systems

Part 3651721, a Flexible Hose, is integral to the efficient operation of various engine components. Its primary function is to facilitate the smooth transfer of gases and fluids between different parts of the engine system, ensuring optimal performance and longevity of the engine.

Integration with Crankcase Breather Systems

In crankcase breather systems, the Flexible Hose connects the crankcase to the air intake tract or the atmosphere. This connection allows for the release of gases that accumulate within the crankcase during engine operation. By providing a pathway for these gases to escape, the hose helps maintain the correct pressure within the crankcase, which is essential for the proper functioning of the engine’s internal components.

Role in CRC Breather Arrangements

When integrated into CRC (Crankcase Ventilation System) breather arrangements, the Flexible Hose plays a key role in managing the flow of crankcase vapors. These vapors, which consist of unburned fuel, moisture, and other byproducts, need to be effectively vented to prevent buildup. The hose ensures that these vapors are directed to the intake manifold, where they can be re-burned, thus reducing emissions and improving fuel efficiency.

Contribution to Overall Breather System Efficiency

The Flexible Hose is also a vital component in broader breather system arrangements. It connects various breather points within the engine, such as the valve cover and the oil pan, to the intake system or the atmosphere. This connectivity ensures that pressure equalization is maintained across different parts of the engine, which is important for the stability and efficiency of engine operations.

Enhancing Engine Performance and Reliability

By efficiently managing the flow of gases and vapors, the Flexible Hose contributes to the overall performance and reliability of the engine. It helps in reducing the risk of oil contamination, extends the lifespan of engine components, and ensures that the engine operates within its designed parameters. This, in turn, leads to better engine performance, lower maintenance costs, and increased durability.

Conclusion

The Cummins 3651721 Flexible Hose is a critical component in the fluid transport systems of commercial trucks. Its design and features ensure efficient, reliable, and durable performance in demanding conditions. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall efficiency and reliability of the vehicle’s engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.