This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

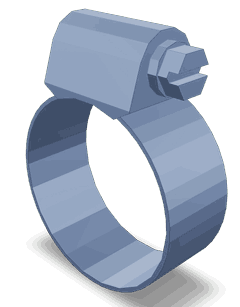

The Cummins 3863522 Hose Clamp is a specialized component designed for use in commercial truck operations. Its primary function is to secure hoses in various truck systems, ensuring that connections remain tight and secure under operational conditions. This clamp plays a role in maintaining the integrity of fluid transfer systems, contributing to the overall efficiency and reliability of truck performance 2.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a leak-free connection. They operate by applying even pressure around the hose, creating a seal that prevents fluid leakage. In automotive and heavy-duty truck systems, hose clamps are vital for securing hoses in fuel, coolant, and hydraulic systems, among others. Their design allows for easy installation and removal, facilitating maintenance and repairs 1.

Purpose of the Cummins 3863522 Hose Clamp

The Cummins 3863522 Hose Clamp is specifically engineered to meet the demanding requirements of commercial truck applications. It plays a role in securing hoses in various truck systems, including fuel lines, coolant systems, and hydraulic circuits. By maintaining a secure connection, this clamp helps ensure the efficient transfer of fluids, contributing to the reliable operation of the truck 2.

Key Features

The Cummins 3863522 Hose Clamp features a robust design that includes a stainless steel band for durability and corrosion resistance. Its worm-drive mechanism allows for precise adjustment, enabling a secure fit on a variety of hose sizes. The clamp’s design also incorporates serrations on the band to grip the hose firmly, reducing the risk of slippage under vibration or pressure fluctuations 2.

Benefits

Utilizing the Cummins 3863522 Hose Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation and adjustment simplifies maintenance procedures, saving time and labor costs. Additionally, the clamp’s design enhances the security of hose connections, minimizing the risk of leaks and ensuring consistent system performance 2.

Installation Process

To install the Cummins 3863522 Hose Clamp, first, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it over the fitting. Use the worm-drive mechanism to tighten the clamp until it achieves a snug fit around the hose and fitting. It is important to avoid over-tightening, which can damage the hose. Once secure, test the connection for leaks under operational conditions 2.

Common Issues and Troubleshooting

Common issues with hose clamps include leaks due to improper installation, corrosion, or wear. To address these problems, inspect the clamp and hose for signs of damage or corrosion. Ensure the clamp is correctly installed and tightened to the appropriate level. If corrosion is present, consider replacing the clamp with a new one to prevent further issues 2.

Maintenance Tips

Regular maintenance of the Cummins 3863522 Hose Clamp involves inspecting the clamp and hose for signs of wear, corrosion, or leaks. Cleaning the clamp and hose periodically can prevent the buildup of debris that may affect performance. Additionally, checking the tightness of the clamp during routine maintenance can help identify any issues before they lead to system failures 2.

Role in Truck Systems

The Cummins 3863522 Hose Clamp is utilized in various truck systems, including the fuel system to secure fuel lines, the coolant system to maintain hose connections in the cooling circuit, and hydraulic systems where it ensures the integrity of fluid lines. Its role in these systems is to provide a secure and leak-free connection, contributing to the efficient operation of the truck 2.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Their product range includes components and systems designed to enhance the performance and efficiency of commercial vehicles 2.

Role of Part 3863522 Hose Clamp in Engine Systems

The part 3863522 Hose Clamp is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple critical areas, including the arrangement of the crankcase breather system, turbocharger plumbing, and general breather configurations 2.

Crankcase Breather System

In the crankcase breather system, the Hose Clamp secures the hoses that vent pressure from the crankcase. This is important for maintaining optimal pressure levels within the crankcase, which in turn ensures the proper functioning of the engine’s internal components. The clamp helps prevent leaks that could lead to contamination of the crankcase oil or inefficient engine performance 2.

Turbocharger Plumbing

For engines equipped with turbochargers, the Hose Clamp is used in the turbocharger plumbing to secure hoses that route air and other fluids. This ensures a tight seal, which is vital for maintaining the turbocharger’s efficiency and longevity. Proper sealing prevents any loss of pressure or fluid, which could otherwise degrade performance or cause damage to the turbocharger 2.

General Breather Configurations

Beyond specific systems, the Hose Clamp is widely used in various breather configurations throughout the engine. These breathers help release built-up pressure from different engine compartments, ensuring that the engine operates within safe parameters. The clamp’s role in these setups is to provide a reliable connection that withstands the dynamic conditions within an engine environment 2.

Plumbing Applications

In broader plumbing applications within the engine, the Hose Clamp is employed to connect various hoses that transport fluids such as coolant, oil, and other essential liquids. This ensures that these fluids are delivered efficiently and without leakage, contributing to the overall reliability and performance of the engine 2.

Conclusion

The Cummins 3863522 Hose Clamp plays a significant role in the functionality and durability of engine systems. Its robust design, ease of installation, and reliable performance make it a critical component for engineers and mechanics working on commercial trucks. Regular maintenance and proper installation are key to ensuring the clamp’s effectiveness in securing hoses and maintaining the integrity of fluid transfer systems 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.