This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3875221 Plain Hose Coupling is a component designed for use in commercial truck systems. Its purpose is to facilitate secure and efficient connections in fluid transfer systems. This coupling plays a role in maintaining the integrity of fluid pathways, ensuring that systems operate smoothly and reliably.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect two ends of a hose, allowing for the transfer of fluids between them. They function by providing a sealed connection that can withstand pressure and movement, which is crucial in dynamic environments such as those found in commercial trucks. These couplings are commonly used in various fluid transfer applications, including fuel, hydraulic, and coolant systems 1.

Purpose and Role in Truck Operation

The Cummins 3875221 Plain Hose Coupling serves a specific purpose in the operation of commercial trucks by ensuring secure and efficient connections in fluid transfer systems. It plays a role in maintaining the integrity of these systems by providing a reliable seal that can handle the pressures and movements inherent in truck operations. This ensures that fluids are transferred effectively without leaks, contributing to the overall efficiency and safety of the vehicle 2.

Key Features

The Cummins 3875221 Plain Hose Coupling features a design that includes robust materials and construction to enhance its performance and durability. It is engineered to provide a secure connection, with elements that allow for easy installation and removal. The coupling is made from materials that resist corrosion and wear, ensuring long-term reliability in demanding environments.

Benefits

Using the Cummins 3875221 Plain Hose Coupling offers several benefits. It provides improved reliability in fluid transfer systems, reducing the risk of leaks and system failures. The design of the coupling allows for ease of installation, minimizing downtime during maintenance procedures. Additionally, its durable construction contributes to lower maintenance requirements, offering cost savings over time 3.

Installation Process

Installing the Cummins 3875221 Plain Hose Coupling involves several steps to ensure a proper and secure connection. First, the hose ends should be prepared by cleaning and cutting to the appropriate length. The coupling is then placed over one end of the hose and secured using the provided clamps or fasteners. The other end of the hose is connected in a similar manner, ensuring that all connections are tight and secure. Tools required may include hose cutters, clamps, and wrenches.

Troubleshooting Common Issues

Common issues with plain hose couplings can include leaks, difficulty in connection, and wear over time. To address these problems, it is important to inspect the coupling and hose ends for damage or misalignment. Ensuring that all connections are tight and that the coupling is properly aligned can resolve many issues. Regular inspection and maintenance can help identify potential problems before they lead to system failures.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3875221 Plain Hose Coupling, regular maintenance practices should be followed. This includes inspecting the coupling and hoses for signs of wear or damage, ensuring that all connections are secure, and replacing any worn or damaged components as needed. Keeping the coupling clean and free from debris can also contribute to its reliable operation.

Safety Considerations

When working with plain hose couplings, it is important to observe safety guidelines to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, when handling couplings and hoses. Ensuring that all connections are secure before operating the system can prevent leaks and other hazards. Additionally, following manufacturer recommendations for installation and maintenance can help ensure the safe and effective use of the coupling.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of commercial applications.

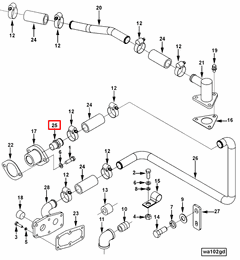

Cummins Engine Part 3875221: Plain Hose Coupling

The Cummins part 3875221, a Plain Hose Coupling, is a critical component in the engine systems of various Cummins engines. This part is designed to ensure a secure and leak-proof connection between hoses and engine components, facilitating the transfer of fluids and gases essential for engine operation.

K19 Engine

In the K19 engine, the Plain Hose Coupling part 3875221 is utilized to connect various fluid lines, ensuring that the engine’s cooling, lubrication, and fuel systems operate efficiently. Its precise fit and robust construction help maintain the integrity of these systems, preventing leaks and ensuring optimal engine performance.

N14 G Engine

For the N14 G engine, the Plain Hose Coupling part 3875221 plays a vital role in the engine’s fluid management systems. This part is integral to the connections within the cooling, lubrication, and fuel systems, ensuring that the engine operates smoothly and efficiently. Its design allows for easy installation and removal, facilitating maintenance and repairs.

NH/NT 855 Engines

In the NH/NT 855 engines, the Plain Hose Coupling part 3875221 is used to connect hoses in the engine’s fluid systems. This part ensures that the engine’s cooling, lubrication, and fuel systems function correctly, contributing to the overall reliability and performance of the engine. Its compatibility with these engines highlights its versatility and importance in maintaining engine integrity.

The Plain Hose Coupling part 3875221 is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines. Its use across various engine models underscores its importance in ensuring the smooth operation and longevity of these engines.

Role of Part 3875221 Plain Hose Coupling in Engine Systems

The Part 3875221 Plain Hose Coupling is an essential component in various engine systems, facilitating secure and efficient fluid transfer across different assemblies.

In the aftercooler water plumbing, this coupling ensures a reliable connection between the aftercooler and the water supply lines, maintaining optimal cooling efficiency for the compressed air.

When integrated into the air intake manifold, the hose coupling provides a robust link between the manifold and the air filter housing, ensuring a consistent airflow into the engine.

For the intercooler piping, the coupling plays a significant role in connecting the intercooler to the intake and exhaust systems, enhancing the cooling of intake air and improving overall engine performance.

In a comprehensive kit, the hose coupling is often included to provide a standardized connection solution for various plumbing needs within the engine system.

The venting system benefits from the coupling by ensuring that pressure relief valves and breather lines are securely connected, preventing any unwanted pressure build-up.

For radiator connection, the coupling is used to join the radiator to the coolant lines, ensuring efficient heat dissipation and maintaining the engine’s operating temperature within safe limits.

In radiator plumbing, the coupling is vital for connecting various components such as the thermostat housing, water pump, and heater core, ensuring a seamless flow of coolant throughout the system.

Radiator plumbing accessories often include this coupling to provide additional connection points and flexibility in routing coolant lines.

A radiator plumbing kit typically features multiple hose couplings to simplify the installation and maintenance of the radiator system.

In a railcar installation package, the coupling is used to ensure all fluid lines are securely connected, accommodating the dynamic environment of rail transport.

For a spares kit, including the hose coupling ensures that maintenance crews have the necessary components to address any plumbing issues that may arise.

In a turbocharger arrangement, the coupling is used to connect the intercooler to the turbocharger, ensuring efficient airflow and cooling, which is essential for maintaining turbocharger performance and longevity.

Conclusion

The Cummins 3875221 Plain Hose Coupling is a vital component in the fluid transfer systems of commercial trucks and various Cummins engines. Its robust design, ease of installation, and reliable performance contribute to the overall efficiency, safety, and longevity of these systems. Regular maintenance and adherence to safety guidelines are essential to ensure the optimal operation of this coupling.

-

Douglas R Carroll, Energy Efficiency of Vehicles, SAE International, 2020.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩ -

Konrad Reif Ed, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.