3908221

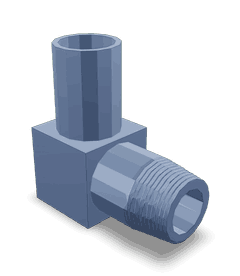

Elbow Hose Coupling

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3908221 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial trucks. It facilitates the transfer of fluids within the truck’s system. Cummins, a well-established name in the automotive industry, produces this coupling as part of its range of reliable and durable components for heavy-duty applications.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, allowing for fluid transfer between components in a system. It is integral to the operation of various fluid systems in trucks, including coolant, fuel, and hydraulic systems. The coupling’s design enables it to withstand pressure and maintain a secure connection, ensuring efficient fluid transfer and system performance 1.

Purpose of the 3908221 Elbow Hose Coupling

This Cummins part is designed to play a role in the fluid transfer systems of commercial trucks. It is applied in scenarios where hoses need to be connected at an angle, providing a reliable connection point that can handle the pressures and temperatures associated with truck operations. Its application spans across different fluid systems, contributing to the overall efficiency and reliability of the truck 2.

Key Features

The 3908221 features a robust design that includes a durable material composition, typically resistant to corrosion and capable of withstanding high pressures. Its design elements are tailored to ensure a secure fit and easy installation, while any unique attributes enhance its performance and longevity in demanding environments 3.

Benefits

This part offers several benefits, including improved system efficiency through reliable fluid transfer, reduced maintenance needs due to its durable construction, and enhanced reliability in operation. These attributes contribute to the overall performance and longevity of the truck’s fluid systems.

Installation and Compatibility

Proper installation of the 3908221 involves following manufacturer guidelines to ensure a secure and efficient connection. Compatibility with various truck models and systems is a key consideration, ensuring that the coupling fits and functions as intended within the specific application.

Troubleshooting and Maintenance

Common issues with the 3908221 may include signs of wear or leaks, which can be addressed through regular inspection and maintenance practices. Ensuring the coupling is properly installed and maintained can help prevent issues and ensure optimal performance and longevity.

Safety Considerations

When working with the 3908221, it is important to observe safety considerations, including proper handling during installation and maintenance. Following recommended procedures helps prevent accidents and ensures the safe operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its history of innovation and commitment to quality. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking. Cummins’ reputation for quality and reliability is built on a foundation of continuous innovation and customer-focused solutions.

Compatibility of Elbow Hose Coupling Part 3908221 with Cummins Engines

The 3908221, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is essential for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring secure and leak-free connections between hoses and engine components.

Group 1: G5.9 and G5.9 CM558 Engines

The 3908221 is compatible with the G5.9 and G5.9 CM558 engines. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The coupling ensures that the hose connections remain tight and secure, preventing any potential leaks that could compromise engine performance.

Group 2: G8.3 and G8.3 CM558 Engines

Similarly, the 3908221 fits the G8.3 and G8.3 CM558 engines. These engines are designed to deliver high power output and efficiency, making them suitable for heavy-duty applications. The coupling’s design ensures that the hoses are properly aligned and secured, which is crucial for maintaining the engine’s operational efficiency.

Group 3: QSB5.9 30 CM550 Engine

The 3908221 is also compatible with the QSB5.9 30 CM550 engine. This engine is known for its versatility and is often used in a range of applications, from agricultural to construction. The coupling ensures that the hose connections are reliable, which is vital for the engine’s cooling and exhaust systems.

Group 4: QSL9 G CM558 Engine

The 3908221 is also suitable for the QSL9 G CM558 engine. This engine is designed for high-performance applications, and the coupling ensures that the hoses are securely connected, preventing any potential issues that could arise from loose connections.

Group 5: 4B3.9, 6B5.9, 6C8.3, ISBE CM800 Engines

Lastly, the 3908221 fits the 4B3.9, 6B5.9, 6C8.3, and ISBE CM800 engines. These engines are known for their durability and efficiency, often used in various industrial and commercial applications. The coupling ensures that the hose connections are secure and reliable, which is essential for maintaining the engine’s performance and longevity.

By ensuring a secure fit and preventing leaks, the 3908221 plays a role in the overall performance and reliability of these Cummins engines.

Role of Part 3908221 Elbow Hose Coupling in Engine Systems

The Elbow Hose Coupling (part 3908221) is a component in various engine systems, facilitating the secure and efficient connection of hoses in multiple applications. Below is an overview of its integration and function within different engine components:

Air Compressor Systems

In air compressor setups, the Elbow Hose Coupling is utilized to connect the air compressor inlet connection to the air compressor inlet kit. This ensures a reliable seal, preventing air leaks and maintaining optimal compressor performance. The coupling’s design allows for flexibility in hose routing, accommodating the dynamic movements of the compressor during operation.

Cabin Heating and Cooling

For cabin heater plumbing, the Elbow Hose Coupling plays a significant role in connecting hoses to the heat exchanger. This connection is vital for the efficient transfer of heated coolant to the cabin, ensuring passenger comfort in cold conditions. The coupling’s durability and leak-proof design are essential for maintaining consistent heater performance.

Coolant and Engine Systems

In the coolant heater starting aid system, the Elbow Hose Coupling is used to connect hoses to the cylinder head and engine coolant vent. This connection aids in preheating the engine coolant, facilitating easier starts in cold weather and protecting engine components from thermal stress.

The coupling is also integral in the engine control module plumbing, where it connects various sensors and control units to the engine’s coolant system. This ensures accurate monitoring and regulation of engine temperature, contributing to overall engine efficiency and longevity.

Turbocharger and Exhaust Systems

In turbocharger arrangements, the Elbow Hose Coupling is employed to connect hoses in the turbocharger location, particularly in systems where intercoolers or charge air coolers are used. This connection helps maintain the integrity of the air supply to the turbocharger, enhancing engine performance and responsiveness.

Fuel and Water Systems

The coupling is also found in the fuel supply tube connections, where it ensures a secure and leak-free link between the fuel tank and the engine’s fuel system. In water inlet connections, particularly in keel cooler plumbing, the Elbow Hose Coupling facilitates the connection of hoses to the cooling system, ensuring efficient heat dissipation and engine cooling.

Additional Applications

In performance part and performance parts setups, the Elbow Hose Coupling is often used to upgrade and enhance various engine systems. Its robust construction and reliable sealing properties make it a preferred choice for high-performance applications, where durability and efficiency are paramount.

Overall, the Elbow Hose Coupling (part 3908221) is a versatile and reliable component, essential for the proper functioning and maintenance of various engine systems.

Conclusion

The 3908221 Elbow Hose Coupling is a critical component in the fluid transfer systems of commercial trucks, offering durability, efficiency, and reliability. Its compatibility with a wide range of Cummins engines underscores its importance in maintaining the performance and longevity of these engines. Proper installation, maintenance, and adherence to safety considerations are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.