This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

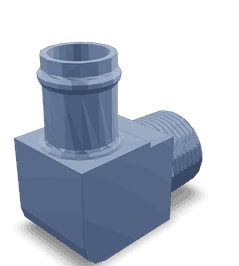

The 3910677 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial trucks. This part plays a role in the fluid systems of these vehicles, facilitating the transfer of fluids under various operational conditions. Cummins, a well-established manufacturer in the industry, produces this part to meet the demanding requirements of commercial truck operations.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used in fluid systems to connect hoses at an angle, typically 90 degrees. This design allows for flexibility in routing hoses around obstacles and within confined spaces. In automotive and industrial applications, these couplings are integral to systems that require fluid transfer, such as coolant, fuel, and hydraulic systems. They enable efficient fluid flow while accommodating the spatial constraints of the installation environment 1.

Purpose of the 3910677 Elbow Hose Coupling

The 3910677 Elbow Hose Coupling is specifically designed to facilitate the connection of hoses in the fluid systems of commercial trucks. Its role involves ensuring a secure and leak-free connection between hoses, which is vital for the proper operation of the truck’s systems. This coupling allows for the efficient transfer of fluids, contributing to the overall performance and reliability of the vehicle.

Key Features

The 3910677 Elbow Hose Coupling features a durable material composition, typically including high-strength polymers or metals, which enhances its resistance to wear and corrosion. Its design incorporates precise fitting mechanisms to ensure a secure connection between hoses. Additionally, the coupling may include features such as reinforced hose ends or integrated clamps to further improve its performance and durability in demanding applications.

Benefits

The use of the 3910677 Elbow Hose Coupling offers several benefits. It improves fluid flow within the system by providing a reliable connection that minimizes the risk of leaks. This enhancement in system reliability can lead to reduced downtime and increased operational efficiency. Furthermore, the durable construction of the coupling can result in potential cost savings through reduced maintenance needs and extended service life.

Installation Considerations

When installing the 3910677 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure proper fitting and function. This may involve using specific tools to achieve the correct torque on fittings and verifying the alignment of hoses to prevent stress on the coupling. Careful attention to these details during installation can help ensure the coupling performs effectively and maintains system integrity.

Troubleshooting Common Issues

Common problems that may arise with the 3910677 Elbow Hose Coupling include leaks or blockages. Troubleshooting these issues effectively involves inspecting the coupling for signs of wear or damage, ensuring that fittings are secure, and checking for proper alignment of connected hoses. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s fluid systems.

Maintenance Tips

Regular maintenance of the 3910677 Elbow Hose Coupling is important to ensure its longevity and optimal performance. This includes routine inspections for signs of wear, corrosion, or damage, and cleaning the coupling as necessary to remove any buildup that could affect its function. Following these maintenance practices can help prevent issues and ensure the coupling continues to perform reliably over time.

Cummins Overview

Cummins is a manufacturer with a strong reputation in the industry, known for producing a wide range of products for commercial trucks. With a history of innovation and quality, Cummins has established itself as a leader in the production of engine and powertrain components. Their products are designed to meet the high demands of commercial truck operations, providing reliability and performance in various applications.

Compatibility of Elbow Hose Coupling Part 3910677 with Cummins Engines

The Elbow Hose Coupling part number 3910677, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This coupling is essential for maintaining the integrity of the engine’s cooling and exhaust systems, ensuring optimal performance and longevity.

Compatible Engines

- 6B5.9

- 6C8.3

- B5.9 G

- ISB CM550

- ISB/ISD4.5 CM2150 B119

- ISBE CM800

- ISBE4 CM850

- QSB5.9 30 CM550

- QSB5.9 44 CM550

Grouping of Compatible Engines

-

ISB Series:

- ISB CM550

- ISB/ISD4.5 CM2150 B119

-

ISBE Series:

- ISBE CM800

- ISBE4 CM850

-

QSB Series:

- QSB5.9 30 CM550

- QSB5.9 44 CM550

-

Other Models:

- 6B5.9

- 6C8.3

- B5.9 G

This part is engineered to ensure a secure and leak-proof connection, which is crucial for the efficient operation of the engine’s systems. Its compatibility across a range of models highlights its versatility and importance in maintaining the performance of Cummins engines.

Role of Part 3910677 Elbow Hose Coupling in Engine Systems

The Elbow Hose Coupling (part number 3910677) serves as a pivotal component in various engine systems, facilitating the efficient transfer of fluids and gases. Its application spans across multiple subsystems, ensuring seamless operation and integration.

Compressor Coolant System

In the compressor coolant system, the Elbow Hose Coupling is employed to redirect the flow of coolant from the compressor to the engine block. This coupling ensures that the coolant effectively absorbs heat from the compressor, maintaining optimal operating temperatures and preventing overheating.

Engine Coolant System

Within the engine coolant system, the Elbow Hose Coupling connects the water inlet to the engine block, allowing for the circulation of coolant throughout the engine. This facilitates consistent temperature regulation, protecting engine components from thermal stress and enhancing overall performance.

Torque Converter Cooler

The Elbow Hose Coupling is integral to the torque converter cooler system, where it manages the flow of fluid between the torque converter and the cooler. This ensures that the torque converter operates within specified temperature ranges, contributing to smooth transmission shifts and prolonged component lifespan.

Cabin Heater Plumbing

In the cabin heater plumbing, the Elbow Hose Coupling plays a role in directing heated coolant from the engine to the cabin heater core. This enables efficient heat transfer to the vehicle’s interior, providing comfort to occupants in colder climates.

Engine Oil Plumbing

For the engine oil system, the Elbow Hose Coupling is used to connect various oil passages, ensuring that oil is distributed evenly across critical engine components. This lubrication is essential for reducing friction and wear, thereby maintaining engine efficiency and reliability.

Block Vent Plumbing

The Elbow Hose Coupling is also found in the block vent plumbing, where it assists in venting gases from the engine block to the atmosphere or recirculation system. This helps in maintaining pressure balance within the engine compartment and preventing the buildup of harmful gases.

Connection to Cooler

In systems involving a cooler, such as the torque converter or engine oil cooler, the Elbow Hose Coupling ensures a secure and leak-free connection between the cooler and the associated plumbing. This is vital for the effective dissipation of heat and the maintenance of system integrity.

Conclusion

Overall, the Elbow Hose Coupling (part 3910677) is a versatile component that enhances the functionality and reliability of various engine systems by ensuring proper fluid and gas flow. Its compatibility with a wide range of Cummins engines underscores its importance in maintaining the performance and longevity of commercial truck operations.

-

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.