This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

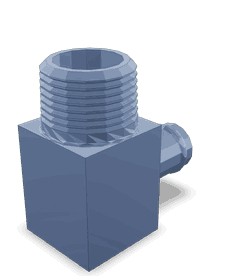

The 3912812 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck systems. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance parts. This part is significant in maintaining the efficiency and functionality of fluid systems within commercial trucks.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid within a system. These couplings are integral to fluid systems as they allow for flexible connections that can accommodate movement and vibration, which are common in vehicle operations. In a truck’s infrastructure, elbow hose couplings ensure that fluid pathways remain intact and functional despite the dynamic environment 1.

Role of the 3912812 Elbow Hose Coupling in Truck Operation

The 3912812 Elbow Hose Coupling plays a specific role in the operation of a commercial truck by connecting hoses at an angle within the fluid systems. It is typically placed in areas where hoses need to change direction, such as around engine components or within the chassis. This coupling manages the flow of fluids, ensuring that systems like cooling, fuel delivery, or hydraulics operate smoothly and efficiently.

Key Features of the 3912812 Elbow Hose Coupling

The 3912812 Elbow Hose Coupling is designed with several features that enhance its performance. It is constructed from durable materials that can withstand the pressures and temperatures of commercial truck applications. The coupling includes secure connection types, such as barb or clamp fittings, to ensure a tight seal. Additionally, it may have unique attributes like reinforced hose ends or corrosion-resistant coatings to improve longevity and reliability.

Benefits of Using the 3912812 Elbow Hose Coupling

Utilizing the 3912812 Elbow Hose Coupling offers several advantages. Its robust construction contributes to improved durability, reducing the likelihood of leaks or failures. The design allows for ease of installation, which can save time during maintenance or repairs. Furthermore, the coupling enhances system efficiency by providing a reliable connection that maintains fluid flow under various operating conditions.

Installation and Integration

Proper installation of the 3912812 Elbow Hose Coupling involves several steps to ensure it functions correctly within the system. Preparatory steps may include cleaning the hose ends and inspecting them for damage. Tools required for installation might include hose cutters, clamps, and wrenches. Integration with other system components should follow manufacturer guidelines to ensure compatibility and secure connections.

Maintenance and Troubleshooting

Regular maintenance practices for the 3912812 Elbow Hose Coupling include periodic inspections for signs of wear, leaks, or corrosion. Cleaning the coupling and ensuring connections remain tight can help prevent issues. Common problems that may arise include hose degradation or coupling misalignment. Troubleshooting steps involve identifying the issue, replacing worn components, and ensuring all connections are secure and properly aligned.

Performance and Reliability

The 3912812 Elbow Hose Coupling demonstrates consistent performance under various operating conditions typical of commercial truck applications. Its reliability is evident in its ability to maintain fluid flow and system integrity over time, even in demanding environments. This performance contributes to the overall efficiency and dependability of the truck’s fluid systems.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality engines and components. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation. Cummins’ reputation for reliability and innovation makes them a trusted choice for truck operators and maintenance professionals 2.

Compatibility with Cummins Engines

The 3912812 Elbow Hose Coupling is designed to fit seamlessly with various Cummins engine models, ensuring efficient fluid transfer and system integrity. This part is particularly compatible with the 6B5.9 and B5.9 G engines, where it plays a role in maintaining the fluid dynamics within the engine’s cooling and exhaust systems.

For the ISB CM550 engine, the 3912812 Elbow Hose Coupling is engineered to integrate smoothly, providing a reliable connection point for hoses that are integral to the engine’s operation. This compatibility ensures that the engine can operate at optimal levels, with the coupling facilitating the necessary fluid flow without leaks or restrictions.

In the context of these engines, the 3912812 Elbow Hose Coupling supports the overall functionality and longevity of the engine systems. Its design allows for easy installation and maintenance, making it a preferred choice for technicians and engineers working with these Cummins engine models.

Role of 3912812 Elbow Hose Coupling in Engine Systems

The 3912812 Elbow Hose Coupling is a component in various engine systems, facilitating the efficient transfer of fluids and gases. Its applications span across several key systems, ensuring optimal performance and reliability.

Block Vent Plumbing

In the block vent plumbing system, the 3912812 Elbow Hose Coupling is utilized to redirect vented gases from the engine block. This coupling ensures that gases are safely routed away from the engine compartment, preventing pressure build-up and potential damage. The coupling’s design allows for a secure connection, minimizing the risk of leaks and ensuring consistent venting.

General Plumbing Systems

Within general plumbing systems, the 3912812 Elbow Hose Coupling serves as a versatile connector. It is employed to join different sections of hoses at angles, accommodating the complex routing required in engine compartments. This flexibility is vital for maintaining efficient fluid flow, whether it be coolant, oil, or other essential liquids.

Cabin Heater System

In the cabin heater system, the 3912812 Elbow Hose Coupling plays a role in directing engine coolant to the heater core. This ensures that warm air is efficiently delivered to the vehicle’s interior. The coupling’s robust construction withstands the high temperatures and pressures associated with engine coolant, ensuring reliable operation in varying conditions.

Torque Converter Cooler

For the torque converter cooler, the 3912812 Elbow Hose Coupling is integral in managing the flow of transmission fluid. It helps in maintaining the optimal temperature of the torque converter, enhancing the transmission’s performance and longevity. The coupling ensures a tight seal, preventing any fluid loss and maintaining the system’s efficiency.

Vent Systems

In vent systems, the 3912812 Elbow Hose Coupling is used to manage the flow of gases and fluids, ensuring that they are properly vented from the engine compartment. This is particularly important in preventing the accumulation of harmful gases and maintaining a safe operating environment.

Engine Coolant System

Within the engine coolant system, the 3912812 Elbow Hose Coupling aids in the circulation of coolant throughout the engine. It connects various components such as the radiator, water pump, and engine block, ensuring that coolant flows smoothly and efficiently. This helps in maintaining the engine’s temperature within safe limits, preventing overheating and potential damage.

Conclusion

The 3912812 Elbow Hose Coupling by Cummins is a vital component in the fluid systems of commercial trucks and engines. Its robust design, ease of installation, and reliable performance make it an essential part for maintaining the efficiency and functionality of these systems. Regular maintenance and proper installation are key to ensuring the longevity and performance of this coupling.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.