This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

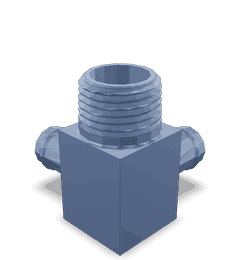

Introduction to Elbow Hose Couplings

Elbow hose couplings are essential components in the fluid transfer systems of commercial trucks and heavy-duty vehicles. These couplings ensure secure and leak-free connections between hoses and other components, facilitating the efficient transfer of fluids such as fuel, coolant, and hydraulic fluids 1.

Functionality of the Cummins 3912977 Elbow Hose Coupling

The Cummins 3912977 elbow hose coupling is designed to provide a robust and reliable connection in high-stress environments. This coupling is commonly used in the engine’s cooling system, where it connects the radiator hose to the engine block. The elbow design allows for a smoother transition in the hose path, reducing stress and wear on the hose and connections. This design enhances the durability of the coupling and improves the overall efficiency of the cooling system 2.

Importance in Truck Operations

In the operation of a commercial truck, the 3912977 elbow hose coupling plays a critical role in maintaining the integrity of the cooling system. A malfunctioning coupling can lead to leaks, overheating, and potential engine damage. Ensuring that this component is in good working condition is essential for the longevity and efficiency of the truck’s engine. Proper maintenance and timely replacement of worn-out couplings can prevent costly downtime and extend the service life of the vehicle 3.

Troubleshooting Common Issues

Regular maintenance and timely troubleshooting can prevent many issues associated with elbow hose couplings. Here are some common problems and their solutions:

-

Leaks: If you notice fluid leaks around the coupling, it may indicate a worn-out seal or damage to the coupling itself. Inspect the coupling for cracks or deformations and replace any damaged parts.

-

Corrosion: Exposure to coolant and other fluids can cause corrosion over time. Regularly inspect the coupling for signs of corrosion and clean or replace as necessary.

-

Secure Connections: Ensure that the coupling is properly tightened and secured. Loose connections can lead to leaks and potential failures.

Maintenance Best Practices

To maintain the reliability of the 3912977 elbow hose coupling, follow these best practices:

-

Regular Inspections: Conduct routine inspections of the coupling and associated hoses. Look for signs of wear, leaks, and corrosion.

-

Proper Tightening: Ensure that the coupling is tightened to the manufacturer’s specifications. Over-tightening can damage the coupling, while under-tightening can lead to leaks.

-

Cleaning: Keep the coupling and surrounding areas clean to prevent the buildup of debris and contaminants that can cause corrosion and blockages.

About Cummins

Cummins is a global leader in the design and manufacturing of engines, engine components, and related technologies. With a strong focus on innovation and quality, Cummins products are trusted by fleet operators and mechanics worldwide. The company’s commitment to excellence ensures that its components, including the 3912977 elbow hose coupling, meet the rigorous demands of commercial truck operations.

Engine Compatibility with Elbow Hose Coupling Part 3912977

The Elbow Hose Coupling part 3912977, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for connecting hoses in a way that allows for smooth fluid transfer while accommodating the natural movement of the engine. Below is a breakdown of the engines that are compatible with this part:

Compatible Engines

- 6B5.9

- B5.9 G

- G855

- GTA855 CM558 (CM2358) G101

- ISB CM550

- N14 G

- QSB5.9 CM850

- QSB6.7 M CM2250

- QSM11 CM570

Grouping of Compatible Engines

-

QSB Series:

- QSB5.9 CM850

- QSB6.7 M CM2250

-

ISB Series:

- ISB CM550

-

N14 Series:

- N14 G

-

G Series:

- G855

- B5.9 G

-

6B Series:

- 6B5.9

-

GTA Series:

- GTA855 CM558 (CM2358) G101

-

QSM Series:

- QSM11 CM570

Each of these engines has specific configurations and requirements, but the Elbow Hose Coupling part 3912977 is engineered to be versatile enough to fit within the design parameters of these engines. This ensures a secure and reliable connection, crucial for maintaining the operational integrity of the engine’s fluid systems.

Role of Part 3912977 Elbow Hose Coupling in Engine Systems

The 3912977 Elbow Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of hoses in multiple applications.

In block vent plumbing, the Elbow Hose Coupling ensures a reliable connection between the engine block and the vent system, allowing for the safe release of gases and preventing pressure build-up within the engine compartment.

For the breather system, this coupling plays a significant role in connecting the breather hose to the crankcase. It allows for the release of pressure and contaminants from the crankcase, maintaining optimal engine performance and longevity.

In crankcase ventilation, the Elbow Hose Coupling is used to link the crankcase to the ventilation system, ensuring that any gases or moisture are effectively expelled, which helps in reducing wear and maintaining clean oil.

Within the module systems, particularly those involving fuel control, the coupling is employed to connect various hoses that transport fuel or other fluids, ensuring a leak-free and stable connection that is vital for the module’s operation.

In plumbing applications across the engine, the Elbow Hose Coupling is utilized to navigate tight spaces and make sharp turns, providing flexibility and durability in hose routing.

For the cabin heater system, this component ensures that the hoses carrying hot coolant to the heater core are securely connected, allowing for efficient heat transfer and comfortable cabin temperatures.

In vent systems, the coupling is critical for connecting vent hoses that release excess pressure or fluids from various engine components, ensuring the system operates within safe parameters.

Lastly, in engine coolant systems, the Elbow Hose Coupling is used to connect hoses that circulate coolant throughout the engine, maintaining optimal temperature and preventing overheating.

Overall, the 3912977 Elbow Hose Coupling is a versatile and reliable component that enhances the functionality and safety of various engine systems.

Conclusion

Understanding the role and maintenance of the Cummins 3912977 elbow hose coupling is crucial for ensuring the efficient and reliable operation of commercial trucks. By following best practices for troubleshooting and maintenance, engineers, mechanics, and fleet operators can extend the life of this critical component and avoid costly downtime.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.