3915488

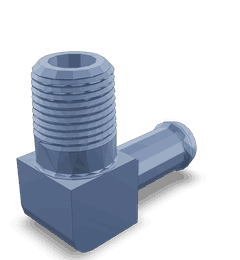

Elbow Hose Coupling

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3915488 Elbow Hose Coupling is a component manufactured by Cummins, a reputable name in the commercial truck industry. This coupling is designed for use in commercial trucks, where it plays a role in the fluid systems that are integral to the vehicle’s operation.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, facilitating the transfer of fluids between components in a system. These couplings are vital in fluid systems as they allow for flexible connections that can accommodate movement and vibration, which are common in the operation of a truck. They operate by providing a secure, leak-proof connection that can withstand the pressures and temperatures of the fluids they carry 1.

Role of the 3915488 Elbow Hose Coupling in Truck Operation

The 3915488 Elbow Hose Coupling is specifically designed to integrate into a truck’s fluid systems, where it connects hoses at an angle to allow for the efficient transfer of fluids. Its role is to ensure that fluids such as coolant, fuel, or hydraulic fluid can flow between components without leakage, even when the truck is in motion and subject to various forces 2.

Key Features of the 3915488 Elbow Hose Coupling

This Cummins part is constructed with materials that are resistant to the corrosive effects of the fluids it carries, as well as the high pressures and temperatures within a truck’s system. It features a design that allows for easy connection and disconnection of hoses, and it may include unique attributes such as reinforced seals or specialized coatings to enhance its performance and longevity 3.

Benefits of Using the 3915488 Elbow Hose Coupling

Utilizing this part offers several advantages. It provides improved fluid flow due to its design, which minimizes restrictions. Its durable construction ensures long-term reliability, and its ease of installation reduces downtime during maintenance procedures.

Installation and Integration

Proper installation of the 3915488 involves ensuring that the coupling is correctly aligned with the hoses and that all connections are secure. This may require the use of specific tools to achieve a proper seal and to prevent damage to the coupling or hoses. Following the manufacturer’s guidelines is important to ensure the coupling functions as intended.

Maintenance and Troubleshooting

To maintain the 3915488, regular inspections should be conducted to check for signs of wear, leaks, or damage. Common issues may include seal failure or corrosion, which can be addressed by replacing worn components or applying protective coatings. Troubleshooting steps should follow a systematic approach to identify and resolve any problems that arise.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the commercial truck industry. They are known for their range of high-quality products that are designed to meet the demanding requirements of commercial vehicles. Their commitment to innovation and customer satisfaction has established them as a leader in the field.

Compatibility of Elbow Hose Coupling Part 3915488 with Cummins Engines

This part is designed to fit seamlessly with a range of Cummins engines. It is integral for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems.

Cummins 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, both part of Cummins’ B Series, are medium-duty diesel engines. The 3915488 is specifically engineered to fit these engines, providing a reliable connection point for hoses that are crucial for the engine’s operation.

Cummins 6C8.3 and B3.3 Engines

The 6C8.3 and B3.3 engines, which belong to Cummins’ C and B Series respectively, also benefit from the 3915488. This part ensures that the hose connections are secure and can withstand the operational stresses of these engines.

Cummins B4.5 Engine

The B4.5 engine, another member of the B Series, is designed for light-duty applications. The 3915488 is compatible with this engine, ensuring that hose connections remain intact and efficient.

Cummins L8.9 Engine

The L8.9 engine, a part of Cummins’ L Series, is a heavy-duty diesel engine. The 3915488 is designed to fit this engine, providing a robust connection for the hoses that are essential for the engine’s cooling and exhaust systems.

Cummins QSB3.9 30 CM550, QSB5.9 30 CM550, QSC8.3 CM554 Engines

The QSB3.9 30 CM550, QSB5.9 30 CM550, and QSC8.3 CM554 engines, which are part of Cummins’ QSB and QSC Series, are designed for a variety of applications. The 3915488 is compatible with these engines, ensuring that hose connections are secure and efficient, supporting the engine’s performance and longevity.

By ensuring that the 3915488 fits these engines, Cummins maintains the reliability and efficiency of their engine systems, providing a critical component for the proper functioning of the engine.

Role of Part 3915488 Elbow Hose Coupling in Engine Systems

The 3915488 is a pivotal component in the integration and functionality of various engine systems. Its primary role is to facilitate the secure and efficient connection between different hoses and fittings within the fuel system, ensuring a seamless flow of fuel throughout the system.

Integration with Fuel System Components

- Fuel System Assembly: The Elbow Hose Coupling is often utilized within the fuel system assembly to connect the fuel inlet to the fuel transfer components. This ensures that fuel is delivered from the fuel tank to the engine with minimal loss or leakage.

- Fuel Inlet and Fuel Drain Location: In systems where the fuel inlet requires a change in direction to align with the fuel drain location, the Elbow Hose Coupling provides the necessary angle adjustment. This is particularly important in compact engine designs where space is at a premium.

- Fitting and Plumbing: The coupling acts as an intermediary fitting in the plumbing of the fuel system, connecting various sections of hose and ensuring that the fuel pathway is uninterrupted. This is essential for maintaining consistent fuel pressure and flow.

- Lift Pump and Fuel Transfer: When integrated with a lift pump, the Elbow Hose Coupling helps in directing the fuel flow from the pump to the fuel transfer components. This ensures that the fuel is efficiently moved from the tank to the engine, enhancing the overall performance of the fuel system.

Additional System Interactions

- Resistor and Corrosion Considerations: In systems where electrical components like resistors are present, the Elbow Hose Coupling helps in maintaining the integrity of the fuel line, preventing any potential corrosion that could affect the electrical components.

- Strainer and Fuel Filtration: The coupling may also be used in conjunction with a strainer to ensure that any contaminants in the fuel are filtered out before the fuel reaches the engine, thus protecting the engine from damage.

- Kit and Repower Applications: During engine repower or when using a kit for fuel system upgrades, the Elbow Hose Coupling is often included to ensure compatibility and ease of installation between new and existing components.

Conclusion

In summary, the 3915488 Elbow Hose Coupling plays a significant role in the efficient operation of engine systems by providing reliable connections within the fuel system, facilitating smooth fuel transfer, and ensuring the integrity of the fuel pathway.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.