This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

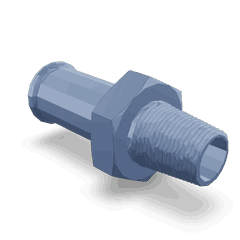

The Cummins 3917458 Plain Hose Coupling Connector is a component designed for use in commercial truck operations. It serves as a vital link in fluid transfer systems, ensuring the efficient and reliable operation of hydraulic and cooling systems within trucks. Its role is significant in maintaining the performance and efficiency of these systems, contributing to the overall functionality of the vehicle 1.

Basic Concepts of Plain Hose Coupling Connectors

Plain hose coupling connectors are devices used to join hoses in fluid transfer systems. They facilitate the secure and leak-free connection of hoses, allowing for the efficient transfer of fluids such as hydraulic oil or coolant. These connectors operate by clamping the hose ends together, creating a seal that prevents fluid leakage and ensures consistent flow through the system. In the context of a truck’s hydraulic or cooling system, these connectors play a role in maintaining system integrity and performance 2.

Role of the 3917458 Plain Hose Coupling Connector in Truck Operation

The 3917458 Plain Hose Coupling Connector plays a specific role in the operation of a truck by ensuring the secure connection of hoses within the hydraulic or cooling systems. This connector contributes to the system’s overall performance and efficiency by providing a reliable seal that prevents fluid leakage. Its function is integral to the consistent operation of these systems, helping to maintain the truck’s performance under various operating conditions 3.

Key Features

The 3917458 Plain Hose Coupling Connector is characterized by several key features that enhance its functionality and durability. These include its material composition, which is designed to withstand the pressures and temperatures encountered in truck systems, and its design elements, which ensure a secure and leak-free connection. Additionally, any unique characteristics of the connector, such as its ease of installation or resistance to corrosion, contribute to its effectiveness in commercial truck applications.

Benefits of Using the 3917458 Plain Hose Coupling Connector

Using the 3917458 Plain Hose Coupling Connector offers several benefits, including improved system reliability due to its secure connection and leak-proof design. Its ease of installation simplifies the process of connecting hoses, reducing downtime during maintenance or repair. Furthermore, the connector’s design facilitates straightforward maintenance, allowing for quick identification and resolution of issues, which contributes to the overall efficiency of truck operations.

Installation Considerations

When installing the 3917458 Plain Hose Coupling Connector, it is important to follow guidelines and best practices to ensure proper fitting and function. This includes verifying the compatibility of the connector with the hoses and system it will be used in, as well as ensuring that the connection is tight and secure to prevent leaks. Specific requirements or recommendations provided by the manufacturer should be adhered to for optimal performance.

Maintenance and Troubleshooting

Maintaining the 3917458 Plain Hose Coupling Connector involves regular inspection for signs of wear or damage, such as cracks or leaks, and addressing any issues promptly to prevent system failure. Common problems may include loose connections or corrosion, which can be resolved by tightening the connector or replacing damaged parts. Troubleshooting tips include checking for proper alignment and ensuring that the connector is compatible with the system’s requirements.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established itself as a provider of innovative and high-quality products in the automotive and engine manufacturing industry. The company’s product range includes engines, filtration systems, and power generation equipment, all designed with a commitment to innovation, quality, and customer satisfaction.

Cummins Engine Part 3917458: Plain Hose Coupling Connector

The Cummins part number 3917458, a Plain Hose Coupling Connector, is a component in the engine systems of various Cummins engines. This part is designed to facilitate the connection between different hoses, ensuring a secure and leak-free interface.

Application in Cummins Engines

6B5.9 Engine

In the 6B5.9 engine, the Plain Hose Coupling Connector (part number 3917458) is utilized to connect various fluid lines, such as coolant, oil, and fuel lines. This connector ensures that the hoses are properly aligned and sealed, preventing any potential leaks that could compromise engine performance or safety.

K19 Engine

Similarly, in the K19 engine, the Plain Hose Coupling Connector (part number 3917458) is employed to link hoses that transport essential fluids. This connector is critical in maintaining the integrity of the engine’s cooling, lubrication, and fuel systems. Its design ensures that the hoses remain securely attached, even under the dynamic conditions experienced during engine operation.

Importance of the Connector

The Plain Hose Coupling Connector is essential for maintaining the operational efficiency and safety of the engine. By providing a reliable connection point, it helps to prevent fluid leaks, which can lead to engine damage, reduced performance, and potential safety hazards. The connector’s design ensures that it can withstand the pressures and temperatures typical of engine environments, making it a durable and reliable choice for these applications.

Role of Part 3917458 Plain Hose Coupling Connector in Engine Systems

The Part 3917458 Plain Hose Coupling Connector is integral to several engine systems, facilitating efficient and secure connections between various components. Here’s how it integrates with specific systems:

Block Vent Plumbing

In block vent plumbing, the Plain Hose Coupling Connector ensures a reliable seal between the block vent and the associated hoses. This connection is vital for maintaining proper ventilation within the engine block, allowing gases to escape without causing pressure buildup, which could lead to engine damage.

CCV System Retrofit Kit

When retrofitting an engine with a Crankcase Ventilation (CCV) system, the Plain Hose Coupling Connector plays a key role. It connects the retrofit kit components to the existing engine system, ensuring that crankcase gases are effectively routed back into the intake system for re-burning, thus reducing emissions and improving engine efficiency.

Air Cleaner

In air cleaner systems, the Plain Hose Coupling Connector is used to link the air cleaner housing to the intake manifold or other components of the air induction system. This ensures a secure and leak-free connection, which is essential for maintaining the correct air-fuel ratio and optimizing engine performance.

Crankcase Valve Drain

For the crankcase valve drain system, the Plain Hose Coupling Connector is employed to connect the drain valve to the appropriate hose leading to the oil pan or another collection point. This connection ensures that any accumulated sludge or contaminants are efficiently drained from the crankcase, preventing potential engine issues.

By providing secure and efficient connections in these systems, the Part 3917458 Plain Hose Coupling Connector contributes to the overall reliability and performance of the engine.

Conclusion

The Cummins 3917458 Plain Hose Coupling Connector is a critical component in both truck and engine systems, ensuring secure and leak-free connections that contribute to the efficiency and reliability of fluid transfer systems. Its design and features make it well-suited for the demanding conditions of commercial truck and engine operations, providing benefits such as improved system reliability, ease of installation, and straightforward maintenance. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the performance and longevity of this connector in its applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.