This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

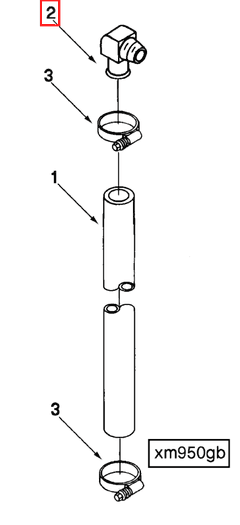

The 3921389 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck systems. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. The 3921389 is significant in maintaining the integrity of fluid transfer systems within these trucks.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect two hoses at an angle, typically 90 degrees. Its general function in fluid systems is to facilitate the transfer of liquids or gases between components while accommodating changes in direction. Within a truck’s hydraulic or cooling system, these couplings ensure that fluid flow is maintained without leakage, even when hoses need to change direction 1.

Purpose of the 3921389 Elbow Hose Coupling

The 3921389 is designed to play a specific role in the operation of a truck. It is applied in various fluid transfer systems, including hydraulic and cooling circuits, where it allows for the redirection of fluid flow. This Cummins part ensures that the system can operate efficiently by maintaining a secure and leak-free connection between hoses.

Key Features

The 3921389 Elbow Hose Coupling boasts several key features that enhance its performance. It is constructed from durable materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes precise fitting mechanisms that provide a secure seal, minimizing the risk of leaks. Additionally, it features easy-to-use clamps that simplify the installation process 2.

Benefits

The advantages provided by the 3921389 include improved fluid flow due to its efficient design, which reduces resistance and ensures smooth operation. Its durability means it can withstand the rigors of commercial truck use, and its ease of installation makes it a practical choice for maintenance and repair tasks.

Installation Process

To install the 3921389, begin by ensuring that the hoses are clean and free from debris. Align the coupling with the hoses and use the provided clamps to secure it in place. Tighten the clamps evenly to avoid damaging the hoses or the coupling. It is recommended to use a torque wrench to achieve the correct tension without over-tightening.

Common Issues and Troubleshooting

Typical problems that may arise with the 3921389 include leaks, which can often be traced to improper installation or wear and tear. To address leaks, check the clamps for proper tension and inspect the coupling for signs of damage. If necessary, replace the coupling or the affected hose section to restore system integrity.

Maintenance Tips

To ensure the longevity and optimal performance of the 3921389, regular maintenance is recommended. Inspect the coupling and hoses for signs of wear or damage during routine checks. Clean the coupling to remove any buildup that could affect its operation. Replace any worn components promptly to prevent system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications 3.

Engine Compatibility with Elbow Hose Coupling Part 3921389 by Cummins

The 3921389, manufactured by Cummins, is designed to fit seamlessly with a variety of engine models. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring secure and leak-proof connections between hoses and engine components.

Compatibility with Specific Engine Models

6B5.9 and 6C8.3 Engines

The 6B5.9 and 6C8.3 engines, both known for their robust performance and reliability, utilize the 3921389 in their design. This part is engineered to fit the specific configurations of these engines, ensuring that the connections are both secure and durable. The precise fitment is critical for maintaining optimal engine performance and preventing any potential leaks that could compromise the engine’s efficiency.

V903 Engine

The V903 engine also benefits from the use of the 3921389. This engine, recognized for its versatility and power, requires a coupling that can withstand high pressures and temperatures. The 3921389 part is designed to meet these demands, providing a reliable connection that enhances the engine’s overall performance and longevity.

Grouping of Engine Models

When considering the compatibility of the 3921389, it is useful to group the engines based on their shared characteristics and requirements. The 6B5.9 and 6C8.3 engines, for example, share similar design philosophies and operational parameters, making them suitable candidates for the same coupling part. Similarly, the V903 engine, while distinct in some aspects, also requires a coupling that can handle the specific stresses and demands of its operation.

By ensuring that the 3921389 is compatible with these engines, Cummins maintains a high standard of quality and reliability, providing engine users with a part that they can trust to perform effectively over time.

Role of Part 3921389 Elbow Hose Coupling in Engine Systems

The 3921389 is an essential component in various engine systems, facilitating the secure and efficient connection between different parts. Its role can be observed in several key areas:

Water Outlet and Cover Plate

The Elbow Hose Coupling is utilized to connect the water outlet to the cover plate. This connection ensures that the coolant flow is directed correctly, maintaining optimal engine temperature and preventing overheating.

Lifting Bracket and Manifold

In systems where a lifting bracket is employed, the Elbow Hose Coupling connects to the manifold. This setup allows for easier maintenance and adjustments, ensuring that the engine components remain accessible without compromising the integrity of the coolant system.

Exhaust and Base Components

When integrated with exhaust systems, the Elbow Hose Coupling connects to the base components, ensuring a secure fit that withstands the high temperatures and pressures of exhaust gases. This connection is vital for maintaining the efficiency and reliability of the exhaust system.

Plumbing and Aftercooler Water

In plumbing applications, particularly with aftercooler water systems, the Elbow Hose Coupling plays a significant role. It ensures that the water flow is consistent and unimpeded, which is essential for the effective cooling of compressed air in aftercoolers.

Keel Cooler and Turbocharger Mounting

The Elbow Hose Coupling is also used in keel cooler systems, where it connects to the turbocharger mounting. This connection is important for maintaining the structural integrity and efficiency of the cooling system, ensuring that the turbocharger operates within optimal temperature ranges.

Water Header Cover

Finally, the Elbow Hose Coupling is employed to connect various components to the water header cover. This connection is crucial for maintaining the overall coolant system’s efficiency, ensuring that all engine parts receive adequate cooling.

Conclusion

The 3921389 Elbow Hose Coupling by Cummins is a vital component in the maintenance and operation of commercial truck systems. Its durable construction, ease of installation, and compatibility with various engine models make it a reliable choice for ensuring secure and leak-free connections in fluid transfer systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.