This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

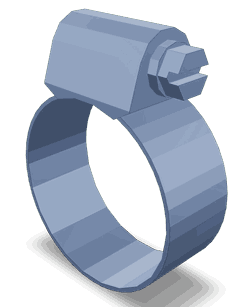

The Hose Clamp 3922843, manufactured by Cummins, is a critical component in the commercial vehicle industry. This part ensures the secure connection of hoses within various systems, contributing to the efficiency and safety of truck operations.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight seal that prevents leaks and maintains system integrity. They are typically made from materials such as stainless steel, aluminum, or composite materials, chosen for their durability, resistance to corrosion, and ability to withstand high temperatures and pressures 1.

Purpose of Hose Clamp 3922843 in Truck Operations

The Hose Clamp 3922843 is designed to support various systems in commercial trucks, including fuel, coolant, and hydraulic systems. It secures hoses to their respective fittings, which is vital for the proper functioning of these systems. The clamp ensures that connections remain intact under varying conditions, contributing to the truck’s operational reliability 2.

Key Features of Hose Clamp 3922843

This Cummins part features a durable material composition, typically a combination of metals for strength and resistance to environmental factors. It utilizes a band type mechanism that allows for easy adjustment and secure fitting around hoses. Unique attributes such as a corrosion-resistant coating and a design that accommodates a range of hose diameters enhance its performance and durability in demanding truck applications 3.

Benefits of Using Hose Clamp 3922843

Utilizing the Hose Clamp 3922843 offers several advantages. It provides improved seal integrity, reducing the risk of leaks that could lead to system failure or environmental contamination. The design of the clamp facilitates ease of installation, allowing for quick adjustments and secure fits. Additionally, its resistance to environmental factors such as moisture, chemicals, and temperature fluctuations ensures long-term reliability in various operating conditions.

Installation and Usage Guidelines

Proper installation of the Hose Clamp 3922843 involves selecting the appropriate size for the hose diameter, positioning the clamp around the hose and fitting, and tightening it to the specified torque. This ensures a secure fit that maintains system integrity without damaging the hose. Best practices include regular inspection of the clamp for signs of wear or corrosion and adjusting the tightness as necessary to accommodate changes in hose flexibility or system pressure.

Troubleshooting Common Issues with Hose Clamps

Frequent problems with hose clamps, such as leaks or clamp failure, can often be traced to improper installation, wear and tear, or environmental degradation. Troubleshooting steps include checking the clamp for proper tightness, inspecting the hose and fitting for damage, and replacing the clamp if signs of corrosion or significant wear are present. Ensuring the clamp is compatible with the hose material and system requirements can also prevent issues.

Maintenance Tips for Hose Clamp 3922843

Regular inspection and maintenance of the Hose Clamp 3922843 are key to ensuring its long-term reliability and performance. This includes checking for signs of wear, corrosion, or loosening, and tightening or replacing the clamp as needed. Keeping the clamp and surrounding areas clean and free of debris can also contribute to its durability. Monitoring the condition of the hoses and fittings it secures is equally important, as damage to these components can compromise the effectiveness of the clamp.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction in the commercial vehicle industry. Its extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Engine Compatibility with Hose Clamp Part 3922843

The Cummins Hose Clamp part number 3922843 is designed to fit a variety of Cummins engines, ensuring a secure and reliable connection for various fluid lines. This part is compatible with the following engines:

Cummins QSB Series Engines

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

Cummins QST Series Engine

- QST30 CM2350 T101

Cummins V Series Engines

- V903

- VTA903 CM2250 V105

Cummins QSB7 Series Engine

- QSB7 CM2880 B117

This compatibility ensures that the 3922843 Hose Clamp can be used across a range of Cummins engines, providing a consistent and reliable solution for securing fluid lines.

Role of Part 3922843 Hose Clamp in Engine Systems

The 3922843 Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in maintaining the integrity of connections across multiple subsystems, facilitating smooth fluid and air flow, and preventing leaks that could compromise engine performance.

Aftercooler System

In the aftercooler mounting and aftercooler tube arrangement, the 3922843 Hose Clamp ensures a tight seal. This is vital for the efficient cooling of compressed air from the turbocharger, which enhances engine efficiency and reduces the risk of overheating.

Turbocharger and Manifold Systems

The clamp is utilized in the turbocharger arrangement and manifold connections, both air intake and exhaust. It secures hoses and pipes that route air and exhaust gases, ensuring that there are no disruptions in the flow which could lead to performance issues or increased emissions.

Cooling Systems

For the engine oil cooler and torque converter oil cooler, the 3922843 Hose Clamp is employed in the cooler and mounting sections. It maintains the necessary pressure and flow rates within the cooling circuits, which is essential for dissipating heat and maintaining optimal operating temperatures.

Breather and Crankcase Systems

In the crankcase breather and exchanger heat systems, the clamp secures connections that allow for the safe release of pressure and contaminants from the crankcase, preventing buildup that could lead to engine damage.

Plumbing and Auxiliary Systems

Within the plumbing sections, such as the compressor air inlet, exhaust outlet connection, and turbocharger, the clamp ensures that all connections are secure. This is particularly important in auxiliary systems where precise fluid dynamics are required for components like the pump and thermostat housing.

Water Management Systems

The clamp is also critical in water management systems, including the water bypass tubes, water outlet connection, water transfer inlet tube, and water transfer tube. It ensures that water flow is consistent and leak-free, which is essential for maintaining engine temperature and preventing corrosion.

Valve Cover and Turbocharger Mounting

Lastly, in the valve cover and turbocharger mounting areas, the 3922843 Hose Clamp secures connections that are exposed to high pressures and temperatures. This ensures the longevity and reliability of these components, contributing to the overall durability of the engine system.

Conclusion

The Hose Clamp 3922843 by Cummins is a vital component in the maintenance and operation of commercial truck systems. Its design, compatibility with various Cummins engines, and role in securing fluid lines across multiple subsystems make it an indispensable part of ensuring engine efficiency, safety, and reliability.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.