This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

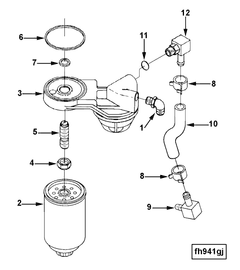

The 3923583 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in the fluid systems of commercial trucks. This coupling facilitates the connection between hoses and other components within the system, ensuring the efficient transfer of fluids such as coolant, fuel, or hydraulic fluid.

Basic Concepts of Elbow Hose Couplings

Elbow hose couplings are fittings used to join hoses at an angle, typically 90 degrees, within a fluid system. They allow for changes in direction of fluid flow without compromising the integrity of the system. In commercial trucks, these couplings are commonly employed in various fluid systems including cooling, fuel delivery, and hydraulic systems, providing flexibility and ease of routing for hoses in confined spaces 1.

Purpose of the 3923583 Elbow Hose Coupling

The 3923583 Elbow Hose Coupling is specifically designed to provide a secure and angled connection between hoses in the fluid systems of trucks. This allows for efficient fluid transfer while accommodating the spatial constraints often found in truck engine compartments. Its function is integral to maintaining the performance and reliability of the truck’s fluid systems.

Key Features

This Cummins part boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding environments. The design includes precision-machined fittings for a secure seal, and it may feature unique attributes such as integrated gaskets or o-rings to prevent leaks 2.

Benefits

Utilizing the 3923583 Elbow Hose Coupling offers several advantages. Its robust construction contributes to improved durability, reducing the frequency of replacements. The design facilitates ease of installation, minimizing downtime during maintenance procedures. Additionally, the coupling enhances system performance by ensuring a reliable and leak-free connection between hoses.

Installation Process

Proper installation of the 3923583 Elbow Hose Coupling involves several steps. Begin by ensuring the hoses are clean and free of debris. Use appropriate tools to connect the coupling to the hoses, ensuring a snug fit. Tighten all connections according to manufacturer specifications to prevent leaks. It is advisable to consult the installation manual for detailed instructions and best practices 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 3923583 Elbow Hose Coupling, regular maintenance is recommended. Inspect the coupling and associated hoses for signs of wear, leaks, or damage during routine maintenance checks. Clean the coupling as necessary to remove any buildup that may affect its function. Following these practices will help maintain the integrity of the fluid system.

Troubleshooting Common Issues

Common issues associated with elbow hose couplings include leaks, blockages, and wear. To diagnose and address these problems, begin by inspecting the coupling and connections for visible signs of damage or wear. Check for leaks by applying pressure to the system and observing for any fluid escape. If a blockage is suspected, disassemble the coupling and clear any obstructions. Replace worn or damaged components as needed to restore system functionality.

Compatibility and Applications

The 3923583 Elbow Hose Coupling is designed for use in various types of trucks and fluid systems. It is commonly employed in cooling, fuel delivery, and hydraulic systems across a range of truck models and series. Compatibility information and specific applications can be found in the product documentation provided by Cummins.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the diverse needs of its customers, contributing to the efficiency and performance of commercial vehicles worldwide.

Engine Compatibility with Elbow Hose Coupling Part 3923583

The Elbow Hose Coupling part number 3923583, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring a secure connection between hoses and engine components.

Cummins 6B5.9 Engine

In the Cummins 6B5.9 engine, the 3923583 Elbow Hose Coupling is utilized to connect the exhaust hose to the turbocharger, ensuring efficient exhaust flow and reducing the risk of leaks. This part is crucial for maintaining the engine’s performance and longevity.

Cummins 6C8.3 Engine

Similarly, in the Cummins 6C8.3 engine, the 3923583 Elbow Hose Coupling is employed to connect the radiator hose to the engine block. This connection is vital for maintaining optimal coolant flow, which is essential for preventing engine overheating and ensuring efficient operation.

Cummins QSC8.3 CM554 Engine

For the Cummins QSC8.3 CM554 engine, the 3923583 Elbow Hose Coupling is used in multiple applications. It connects the intake manifold to the air cleaner, ensuring a proper seal and preventing air leaks. Additionally, it is used to connect the radiator hose to the engine block, similar to its function in the 6C8.3 engine. This part’s versatility makes it a key component in maintaining the engine’s efficiency and reliability.

By ensuring a secure and leak-free connection, the 3923583 Elbow Hose Coupling plays a critical role in the overall performance and durability of these Cummins engines.

Role of Part 3923583 Elbow Hose Coupling in Engine Systems

The 3923583 Elbow Hose Coupling is an essential component in the fluid dynamics of engine systems, particularly in the context of fuel management and transfer. This coupling facilitates the secure and efficient connection between various hoses and components within the fuel system, ensuring a seamless flow of fuel from one point to another.

Integration with Fuel Filter

In the fuel system, the Elbow Hose Coupling is often used to connect the fuel filter to adjacent components. This connection is vital for maintaining the integrity of the fuel line, allowing for the smooth passage of fuel while preventing leaks. The coupling’s design ensures that the connection is both robust and flexible, accommodating the vibrations and movements inherent in engine operation.

Connection to Fuel Pump

The coupling also plays a significant role in linking the fuel pump to the fuel lines. This connection is fundamental for the efficient transfer of fuel from the tank to the engine. The Elbow Hose Coupling ensures that the fuel pump can operate without interruption, providing a consistent supply of fuel under varying engine loads and conditions.

Fuel Transfer Applications

In systems where fuel transfer between tanks or compartments is necessary, the 3923583 Elbow Hose Coupling is employed to connect the transfer pump to the hoses. This application is common in vehicles with dual fuel tanks or in aviation fuel systems where balancing fuel load is essential. The coupling’s durability and leak-proof design are paramount in these scenarios, ensuring safe and efficient fuel transfer.

Overall System Contribution

Across these applications, the 3923583 Elbow Hose Coupling contributes to the reliability and efficiency of the fuel system. By providing a secure and flexible connection point, it allows for the dynamic nature of engine systems to be accommodated without compromising the integrity of the fuel lines. This component is a testament to the engineering precision required in modern engine systems, ensuring that fuel is delivered where it’s needed, when it’s needed, without loss or leakage.

Conclusion

The 3923583 Elbow Hose Coupling is a vital component in the fluid systems of commercial trucks, offering durability, ease of installation, and enhanced system performance. Its role in maintaining secure and efficient fluid transfer across various engine systems underscores its importance in the reliability and efficiency of commercial vehicles.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Konrad Reif. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). QSB5.9 CM2880 B139, Service Manual (4388870).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.