This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

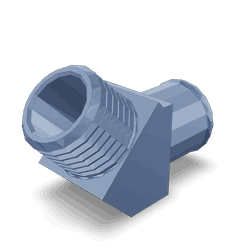

The Elbow Hose Coupling 3935851, manufactured by Cummins, is a component designed for use in commercial truck systems. Cummins, a well-established name in the industry, produces a range of parts that contribute to the efficiency and reliability of heavy-duty vehicles. This part is significant in maintaining the integrity of fluid systems within these trucks.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees, allowing for a change in direction within a fluid system. These couplings are integral to the operation of fluid systems, facilitating the transfer of liquids or gases between components while accommodating spatial constraints and routing requirements within a truck’s infrastructure 1.

Purpose of the 3935851 Elbow Hose Coupling

The 3935851 Elbow Hose Coupling is specifically designed to play a role in the operation of commercial trucks by connecting hoses in systems that require a directional change. It is applied in various fluid systems, including coolant, fuel, and hydraulic lines, ensuring that fluids are efficiently routed throughout the vehicle. This coupling helps maintain system pressure and flow, contributing to the overall performance and reliability of the truck.

Key Features

The 3935851 Elbow Hose Coupling boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise machining for a secure fit and optimal performance. Additionally, it may feature unique characteristics such as reinforced hose ends or specialized seals to further improve its effectiveness in demanding environments.

Benefits

The advantages of using the 3935851 Elbow Hose Coupling include improved fluid flow due to its design, which minimizes restrictions and ensures smooth transit of fluids. It also reduces the risk of leakage, enhancing system reliability. The coupling is designed for ease of installation, allowing for quick and efficient setup in various applications.

Installation Considerations

Proper installation of the 3935851 Elbow Hose Coupling is vital for its performance and longevity. Guidelines for installation include adhering to specified torque values to ensure a secure connection without over-tightening, which could damage the coupling or hoses. Alignment with other system components is also crucial to maintain the intended fluid path and system efficiency.

Maintenance and Troubleshooting

Routine maintenance of the 3935851 Elbow Hose Coupling involves regular inspection for signs of wear, corrosion, or leaks. Cleaning the coupling and ensuring that all connections are tight can help prevent issues. Troubleshooting common problems such as leaks or blockages may involve checking for proper alignment, inspecting seals for damage, and ensuring that the coupling is compatible with the hoses and system pressures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components that contribute to the efficiency, reliability, and performance of heavy-duty vehicles, reflecting Cummins’ dedication to customer satisfaction and technological advancement 2.

Role of Part 3935851 Elbow Hose Coupling in Engine Systems

The part 3935851 Elbow Hose Coupling is instrumental in facilitating the fluid dynamics within various engine systems. It acts as a pivotal junction in the connection between different components, ensuring smooth and efficient operation.

Connection

In the context of engine systems, the Elbow Hose Coupling serves as a vital link in the connection network. It allows for the redirection of fluid pathways, accommodating the spatial constraints within the engine compartment. This part ensures that hoses can be routed efficiently around other components without kinking or stressing the hose material, which is essential for maintaining the integrity of the fluid transport system.

Water Inlet

At the water inlet, the Elbow Hose Coupling plays a significant role in directing coolant flow into the engine block. It provides a secure and leak-proof connection between the coolant hose and the water inlet port. This ensures that coolant is delivered consistently to the engine, aiding in temperature regulation and preventing overheating. The coupling’s design allows for easy installation and removal, facilitating maintenance and replacement when necessary.

Exhaust Manifold

In systems where the Elbow Hose Coupling is used near the exhaust manifold, it assists in managing the routing of hoses that may be part of emissions control systems or secondary air injection systems. By providing a robust and durable connection point, it helps in withstanding the high temperatures and vibrations associated with the exhaust manifold. This ensures that the hoses remain intact and functional, contributing to the overall efficiency and reliability of the emissions control system.

Conclusion

The 3935851 Elbow Hose Coupling by Cummins is a critical component in the fluid systems of commercial trucks and engines. Its design and features ensure efficient fluid transfer, maintain system integrity, and contribute to the overall performance and reliability of the vehicle. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its benefits and ensuring the longevity of the fluid systems it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.