This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

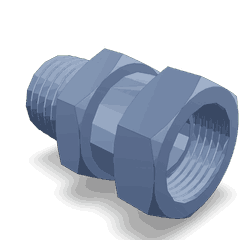

The Cummins 3936170 Hose Swivel is a specialized component designed for use in commercial trucks. It facilitates the transfer of fluids within the vehicle’s systems, ensuring smooth operation and efficiency. This part is integral to maintaining the functionality of various fluid transfer systems in heavy-duty applications.

Basic Concepts of Hose Swivels

A hose swivel is a mechanical device that allows for the rotation of a hose while maintaining a continuous flow of fluid. It is commonly used in systems where hoses need to move or rotate without disrupting the flow. The swivel mechanism typically consists of a central pivot point that enables the hose to rotate 360 degrees, accommodating the movement of connected equipment without kinking or restricting the flow 1.

Purpose of the Cummins 3936170 Hose Swivel

The Cummins 3936170 Hose Swivel plays a role in the fluid transfer systems of commercial trucks by allowing hoses to rotate freely. This flexibility is vital in applications where equipment movement is frequent, such as in cranes, excavators, and other heavy machinery. By enabling unrestricted rotation, the swivel helps maintain consistent fluid flow, which is crucial for the efficient operation of hydraulic and pneumatic systems 2.

Key Features

The Cummins 3936170 Hose Swivel is characterized by its robust design and high-quality materials. It is constructed from durable metals that can withstand the rigors of heavy-duty use. The swivel features precision-machined components that ensure smooth operation and reliable performance. Additionally, it is designed to accommodate a range of hose sizes, making it versatile for various applications 3.

Benefits

The Cummins 3936170 Hose Swivel offers several advantages. Its design enhances flexibility, allowing for unrestricted movement of connected hoses. This reduces the risk of kinking and wear, which can lead to leaks or system failures. The swivel’s durable construction ensures longevity, even in demanding environments. Furthermore, its reliable performance contributes to the overall efficiency of the fluid transfer system.

Installation Considerations

When installing the Cummins 3936170 Hose Swivel, it is important to follow specific guidelines to ensure proper function and safety. The installation process typically requires basic hand tools and may involve disconnecting and reconnecting hoses. It is crucial to ensure that all connections are secure and that the swivel is properly aligned with the system’s movement requirements. Safety precautions, such as wearing protective gear and ensuring the system is depressurized, should be observed during installation.

Troubleshooting Common Issues

Common issues with hose swivels may include leaks, restricted flow, or swivel malfunction. These problems can often be traced to improper installation, wear and tear, or damage to the swivel components. Regular inspection and maintenance can help identify potential issues before they lead to system failures. Solutions may involve tightening connections, replacing worn components, or, in some cases, replacing the swivel entirely.

Maintenance Tips

To ensure the longevity and reliable operation of the Cummins 3936170 Hose Swivel, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or damage. Lubricating moving parts can help maintain smooth operation, while cleaning the swivel and its connections can prevent buildup that may restrict flow. Following the manufacturer’s maintenance schedule and guidelines will help ensure optimal performance and extend the lifespan of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck and heavy-duty equipment industries. The company offers a wide range of products and services designed to meet the needs of various applications, from on-highway transportation to off-highway construction and industrial uses.

Cummins Hose Swivel Part 3936170 Compatibility

The Cummins Hose Swivel part number 3936170 is a critical component designed to facilitate the connection and disconnection of various hoses within the engine system. This part is engineered to ensure a secure and leak-proof connection, which is essential for maintaining the integrity of the engine’s hydraulic and fuel systems.

Engine Compatibility

The Hose Swivel part 3936170 is compatible with a range of Cummins engines, including but not limited to:

- 6B5.9: This engine model benefits from the Hose Swivel’s ability to provide a reliable connection point for fuel and hydraulic hoses, ensuring smooth operation and reducing the risk of leaks.

Installation and Function

In the context of the 6B5.9 engine, the Hose Swivel part 3936170 is typically installed in areas where hoses need to be frequently connected and disconnected, such as fuel lines or hydraulic lines. Its design allows for easy rotation and secure locking, which simplifies maintenance tasks and enhances operational efficiency.

Importance in Engine Systems

The Hose Swivel part 3936170 plays a vital role in the overall functionality of the engine by providing a robust connection point for hoses. This is particularly important in high-stress environments where hoses are subject to frequent movement and pressure changes. By ensuring a secure and leak-proof connection, the Hose Swivel helps maintain the performance and reliability of the engine.

Role of Part 3936170 Hose Swivel in Engine Systems

The Hose Swivel, identified by part number 3936170, is integral to the efficient operation of various engine systems. Its primary function is to facilitate the flexible connection between components that require a degree of movement or rotation.

In the context of an arrangement involving multiple engine components, the Hose Swivel ensures that the connections remain intact and functional despite the dynamic nature of the engine’s operation. This flexibility is essential for maintaining consistent performance and preventing potential damage from rigid connections.

When integrated with the compressor air inlet, the Hose Swivel allows for the smooth transfer of compressed air into the system. This is particularly important in applications where the compressor and inlet may not be perfectly aligned or may experience slight movements during operation. The swivel joint accommodates these variations, ensuring a steady airflow without compromising the integrity of the connection.

In terms of connection to the air compressor inlet, the Hose Swivel plays a significant role in reducing stress on the hose and the connected components. By allowing rotational movement, it prevents kinks and twists that could otherwise impede airflow or lead to hose failure. This is especially beneficial in high-pressure systems where maintaining a consistent and unobstructed path for air is essential for optimal performance.

Overall, the incorporation of the Hose Swivel in these engine systems enhances reliability and durability, ensuring that the components can operate efficiently under a range of conditions.

Conclusion

The Cummins 3936170 Hose Swivel is a critical component in the fluid transfer systems of commercial trucks and heavy-duty machinery. Its robust design, flexibility, and reliable performance make it essential for maintaining the efficiency and functionality of hydraulic and pneumatic systems. Regular maintenance and proper installation are key to ensuring the longevity and optimal operation of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.