This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

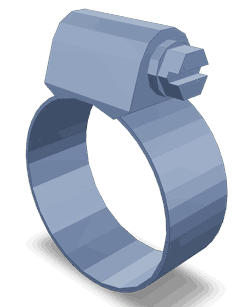

The Cummins 3936552 Hose Clamp is a component designed to secure hoses in various fluid systems within commercial trucks. Its role is significant in maintaining the integrity and efficiency of these systems, ensuring that fluids are transported securely and without leaks 1.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings in fluid systems. They operate by compressing the hose against the fitting, creating a seal that prevents fluid leakage. Hose clamps are essential in systems where vibrations and movements are common, as they provide a reliable means to maintain a secure connection 2.

Purpose of the Cummins 3936552 Hose Clamp

The Cummins 3936552 Hose Clamp is utilized in several truck systems, including fuel, coolant, and hydraulic systems. It plays a role in securing hoses within these systems, ensuring that fluids are delivered efficiently and without interruption. By maintaining a tight seal, it helps prevent leaks and ensures the systems operate within their designed parameters 3.

Key Features

The Cummins 3936552 Hose Clamp is constructed with durability and performance in mind. It features a band typically made from stainless steel, which offers resistance to corrosion and wear. The clamp utilizes a screw mechanism to adjust the tension, allowing for precise fitting. Its design ensures a consistent and reliable seal, even under varying conditions 4.

Benefits

Using the Cummins 3936552 Hose Clamp provides several advantages. It offers improved seal integrity, reducing the risk of leaks in fluid systems. The clamp’s design allows for ease of installation and removal, making maintenance tasks more straightforward. Its resistance to corrosion ensures longevity, even in harsh operating environments. Additionally, the clamp’s reliable performance contributes to the overall efficiency and safety of the truck’s systems 5.

Installation Process

Installing the Cummins 3936552 Hose Clamp requires careful attention to ensure a secure fit. Begin by positioning the clamp around the hose and fitting. Use the screw mechanism to gradually tighten the clamp, ensuring even pressure around the hose. It is important to achieve the correct tension to maintain a seal without damaging the hose. Tools such as a wrench may be required to properly secure the clamp 6.

Troubleshooting Common Issues

Common issues with hose clamps include leaks, corrosion, and improper fitting. To address leaks, check the clamp’s tension and ensure it is correctly positioned. Corrosion can be mitigated by selecting clamps made from corrosion-resistant materials. Improper fitting may require adjusting the clamp or replacing it if damaged 7.

Maintenance Tips

Regular inspection and maintenance of the Cummins 3936552 Hose Clamp are recommended to ensure continued performance. Inspect the clamp for signs of wear or corrosion, and tighten it if necessary to maintain a secure seal. Cleaning the clamp and surrounding areas can prevent buildup that may affect its operation. Replacement guidelines should be followed if the clamp shows significant wear or damage 8.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ reputation is built on its dedication to providing reliable and efficient solutions for the transportation sector 9.

Role of Part 3936552 Hose Clamp in Engine Systems

The 3936552 Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems, particularly in arrangements involving turbochargers.

In a turbocharger arrangement, the Hose Clamp secures hoses that transport fluids such as coolant or oil, ensuring a tight and reliable connection. This is essential for maintaining consistent fluid flow, which is vital for the lubrication and cooling of turbocharger components.

Furthermore, the Hose Clamp plays a significant role in preventing leaks that could lead to performance issues or damage to the turbocharger. By ensuring that hoses remain firmly attached under varying engine conditions, the Hose Clamp contributes to the overall stability and performance of the turbocharger system 10.

Conclusion

The Cummins 3936552 Hose Clamp is a critical component in the maintenance and operation of commercial truck fluid systems. Its design and features ensure reliable performance, ease of maintenance, and durability in harsh environments. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.