This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

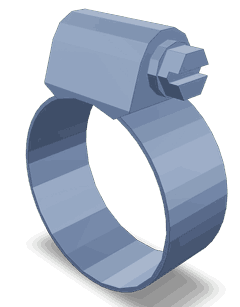

The Hose Clamp 3936553, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This part is designed to secure hoses in various systems within commercial trucks, ensuring efficient and safe operation. Its role in maintaining the integrity of hose connections is significant, contributing to the overall reliability and performance of truck systems.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are essential in various fluid transfer systems, including fuel, coolant, and hydraulic lines. Hose clamps come in several types, such as worm-drive, spring, and wire clamps, each suited to different applications based on the required clamping force and environmental conditions.

Purpose of Hose Clamp 3936553 in Truck Operations

The Hose Clamp 3936553 is specifically designed for use in commercial truck operations. It plays a role in securing hoses in critical systems such as the fuel delivery, coolant circulation, and hydraulic systems. Secure hose connections are vital for the efficient operation of these systems, preventing leaks that could lead to system failures or safety hazards. The clamp ensures that hoses remain firmly attached under various operating conditions, including vibrations and temperature fluctuations.

Key Features of Hose Clamp 3936553

The Hose Clamp 3936553 is characterized by several distinctive features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes a robust clamping mechanism that provides a consistent and reliable grip on the hose. Additionally, the clamp is engineered to accommodate a range of hose sizes, making it versatile for various applications within the truck.

Benefits of Using Hose Clamp 3936553

Employing the Hose Clamp 3936553 in truck maintenance and operations offers several advantages. Its reliable clamping mechanism ensures secure hose connections, reducing the risk of leaks and system failures. The ease of installation allows for quick replacement or adjustment, minimizing downtime. Furthermore, the durability of the clamp contributes to long-term cost savings by reducing the frequency of replacements and maintenance interventions.

Installation and Usage Guidelines

Proper installation of the Hose Clamp 3936553 involves several steps to ensure optimal performance. Begin by selecting the appropriate clamp size for the hose diameter. Position the clamp around the hose and fitting, ensuring it is aligned correctly. Use the provided tool to tighten the clamp gradually, applying even pressure to avoid damaging the hose. Verify the connection by checking for leaks and ensuring the clamp is securely fastened. The clamp is compatible with various hose types and sizes, making it a versatile choice for different truck systems.

Troubleshooting Common Issues

Frequent problems with hose clamps may include leaks, loose connections, or clamp failure. These issues can arise from improper installation, wear and tear, or environmental factors. To address leaks, inspect the clamp and hose for damage, ensuring the clamp is correctly positioned and tightened. Loose connections may require re-tightening or replacement of the clamp. In cases of clamp failure, assess the material and environmental conditions to select a more suitable replacement.

Maintenance Tips for Hose Clamp 3936553

Regular maintenance of the Hose Clamp 3936553 is key to prolonging its life and ensuring reliable performance. Inspect the clamp and hose connections routinely for signs of wear, corrosion, or leaks. Clean the clamp and surrounding areas to remove dirt and debris that could affect performance. Consider replacing the clamp if it shows significant wear or if hose connections frequently fail. Adhering to these maintenance practices will help maintain the integrity of the truck’s fluid transfer systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and emission solutions. Cummins’ dedication to excellence is evident in its comprehensive approach to product development and customer support. 1

Cummins Hose Clamp 3936553 Compatibility with Engine Models

The Cummins Hose Clamp part number 3936553 is designed to fit seamlessly with various engine models, ensuring a secure and leak-proof connection for hoses and pipes. This clamp is essential for maintaining the integrity of the engine’s cooling, fuel, and exhaust systems.

Engine Models

- 6B5.9 Series: The 3936553 Hose Clamp is specifically engineered to fit the 6B5.9 engine series. This engine model is known for its robust performance and reliability, often used in heavy-duty applications. The clamp ensures that all hose connections remain tight and secure, preventing any potential leaks that could compromise engine performance.

The 3936553 Hose Clamp is a critical component for maintaining the operational efficiency and safety of the engines it is used with. Its compatibility with the 6B5.9 series underscores its versatility and importance in the engine’s overall system.

Role of Part 3936553 Hose Clamp in Engine Systems

The part 3936553 Hose Clamp is an essential component in ensuring the integrity and efficiency of various engine systems. In the context of an engine’s turbocharger arrangement, this hose clamp plays a significant role.

Turbocharger Arrangement

In a turbocharger arrangement, the hose clamp secures the hoses that connect the turbocharger to the intercooler, intake manifold, and exhaust system. This ensures that the airflow through these components remains consistent and unimpeded, which is vital for the turbocharger’s performance. The clamp prevents hose disconnections and leaks, maintaining the pressure differentials necessary for efficient turbocharging.

Turbocharger

When considering the turbocharger itself, the hose clamp is used to secure the hoses that supply air to the turbine and those that route the compressed air to the engine’s intake system. This secure attachment is important for maintaining the turbocharger’s operational efficiency and longevity. It ensures that the air supply is consistent, which helps in achieving the desired boost levels without compromising the system’s integrity.

Overall Engine Arrangement

In the broader engine arrangement, the hose clamp is utilized across various hose connections, including those related to the cooling system, fuel delivery, and emissions control systems. By ensuring these hoses remain firmly in place, the clamp contributes to the overall reliability and performance of the engine. It helps in preventing coolant leaks, fuel line disruptions, and emissions system failures, thereby supporting the engine’s consistent operation.

Conclusion

The Hose Clamp 3936553 by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its robust design, ease of installation, and compatibility with various engine models make it an indispensable part of ensuring the integrity and efficiency of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall reliability and performance of the vehicles it serves.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.