This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

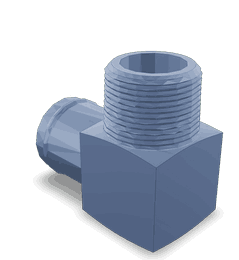

The 3954920 Elbow Hose Coupling, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Its primary role is within the fluid transfer systems of these vehicles, where it facilitates the connection of hoses at an angle. This design allows for efficient fluid flow and reduces stress on the hose, contributing to the overall reliability and performance of the truck’s systems. Hose couplings, in general, play a vital role in ensuring that fluids are transferred smoothly and efficiently throughout the vehicle, supporting various critical functions 2.

Function and Operation

The 3954920 operates by connecting hoses at an angle within a truck’s fluid transfer system. This angled connection is crucial for maintaining the integrity of the hose and ensuring that fluid flows smoothly without unnecessary bends or stress points. By facilitating an efficient fluid flow, the coupling helps in reducing the wear and tear on the hose, thereby enhancing the system’s longevity. Its design also plays a role in minimizing the risk of leaks and connection failures, which are common concerns in fluid transfer systems 3.

Key Features

The design of the 3954920 incorporates several elements that enhance its performance and durability. It is constructed from materials that are resistant to the pressures and temperatures encountered in commercial truck applications. The coupling features a specific connection type that ensures a secure fit with the hoses, and it is rated for certain pressure levels, making it suitable for various fluid transfer applications. Additionally, unique attributes such as its angled design and robust construction contribute to its effectiveness in demanding environments 4.

Benefits

The 3954920 offers several advantages that contribute to the efficiency and reliability of a truck’s systems. Improved fluid dynamics are achieved through its angled connection, which allows for a smoother flow of fluids. Its durable construction ensures long-term performance, even under challenging conditions. Ease of installation is another benefit, as the coupling is designed to be quickly and securely attached to hoses. Maintenance benefits include reduced need for frequent replacements and easier access for inspections and repairs, which can lead to cost savings and increased uptime for the vehicle 1.

Installation Considerations

Proper installation of the 3954920 is crucial for its optimal performance and longevity. Guidelines for installation include adhering to specified torque settings to ensure a secure connection without overtightening, which could damage the coupling or hose. Alignment procedures are also important to maintain the integrity of the fluid transfer system. Compatibility with various hose types and sizes should be considered to ensure a proper fit and function. Correct installation practices are emphasized to prevent issues such as leaks or connection failures 2.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and reliability of the 3954920. Regular inspections can help identify potential issues before they lead to failures. Common problems that may arise include leaks or connection failures, which can often be addressed through proper maintenance and timely replacements. Troubleshooting steps may involve checking for proper alignment, ensuring the coupling is securely fastened, and inspecting for signs of wear or damage. The importance of regular maintenance cannot be overstated, as it contributes to the overall efficiency and safety of the truck’s systems 3.

Applications

The 3954920 is suitable for a variety of applications within commercial trucks, including coolant systems, hydraulic systems, and pneumatic systems. Its design, which allows for angled connections, makes it particularly useful in these applications where space constraints or the layout of the system may require hoses to be connected at an angle. The coupling’s robust construction and secure connection type ensure it can handle the pressures and temperatures associated with these systems, contributing to their efficient operation 4.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established manufacturer with a rich history in the production of diesel engines and related technologies. The company is recognized for its commitment to quality and innovation, which is evident in its wide range of products designed for the commercial truck industry. Cummins’ expertise in engine technology and component manufacturing has earned it a reputation for producing reliable and high-performance parts. The company’s role in the commercial truck industry is significant, providing components that contribute to the efficiency, reliability, and durability of trucks worldwide.

Compatibility of Elbow Hose Coupling Part 3954920 with Cummins Engines

The 3954920, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems. Here is a detailed look at the compatibility of this part with various Cummins engines:

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The ISB series engines are known for their robust performance and reliability. The 3954920 is compatible with these engines, ensuring that the connections between hoses and the engine are secure and leak-proof. This is particularly important for maintaining the efficiency of the engine’s cooling and exhaust systems.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines are designed for heavy-duty applications, and the 3954920 is engineered to fit these engines seamlessly. This ensures that the connections are durable and can withstand the rigors of heavy-duty use.

ISC and ISL Series Engines

- ISC CM2150

- ISL CM2150

The ISC and ISL series engines are typically used in on-highway and vocational applications. The 3954920 is compatible with these engines, providing a reliable connection that is essential for the proper functioning of the engine’s systems.

QSB Series Engines

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

The QSB series engines are designed for a range of applications, from agricultural to construction. The 3954920 fits these engines, ensuring that the connections are secure and can handle the demands of these varied applications.

By ensuring compatibility with these engines, the 3954920 plays a vital role in maintaining the performance and reliability of Cummins engines across a wide range of applications.

Role of Part 3954920 Elbow Hose Coupling in Engine Systems

The Elbow Hose Coupling (part number 3954920) is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases between different parts. Its role can be observed in the following applications:

Compressor Air Inlet System

In the compressor air inlet system, the Elbow Hose Coupling ensures a secure and leak-free connection between the air intake hose and the compressor. This connection is vital for maintaining the integrity of the air supply, which is compressed to increase engine efficiency and performance. The coupling’s design allows for flexibility and reduces stress on the hose, enhancing durability and reliability.

Cooling System

Within the cooler system, the Elbow Hose Coupling connects the coolant hoses to the radiator and other cooling components. This ensures that coolant flows smoothly through the system, dissipating heat effectively to prevent engine overheating. The coupling’s robust construction withstands the pressure and temperature variations within the cooling system, contributing to consistent engine operation.

Torque Converter Oil System

In the torque converter oil system, the Elbow Hose Coupling plays a role in connecting the oil lines that supply lubricant to the torque converter. This ensures that the torque converter receives a steady flow of oil, which is essential for smooth transmission operation and reducing wear on internal components. The coupling’s precise fit and sealing properties are key to maintaining oil pressure and preventing leaks.

General Arrangement

Across various engine arrangements, the Elbow Hose Coupling is used to join different hoses and pipes, providing a versatile solution for fluid and gas transfer. Its application in these systems highlights its importance in maintaining the overall functionality and efficiency of the engine. The coupling’s ability to adapt to different angles and configurations makes it a valuable component in complex engine designs.

Conclusion

The 3954920 Elbow Hose Coupling is a critical component in the fluid transfer systems of commercial trucks, offering benefits such as improved fluid dynamics, durability, ease of installation, and maintenance advantages. Its compatibility with various Cummins engines underscores its importance in maintaining the performance and reliability of these engines. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this Cummins part.

-

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ ↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩ ↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.