This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

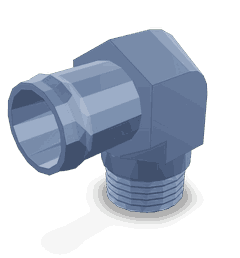

The 3957657 Elbow Hose Coupling, a component manufactured by Cummins, plays a significant role in the operation of commercial trucks. This coupling is integral to the efficiency and reliability of various fluid systems within these vehicles.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used in fluid systems to connect hoses at an angle, typically 90 degrees. Its primary function is to facilitate the transfer of fluids such as coolant, fuel, or hydraulic fluid between components within a truck’s subsystems. The coupling allows for changes in direction of the hose routing, accommodating the complex layouts of modern truck engines and systems 1.

Role of the 3957657 Elbow Hose Coupling in Truck Operations

The 3957657 Elbow Hose Coupling enables the connection of hoses in coolant, fuel, and hydraulic systems. In the coolant system, it helps manage the flow of coolant to and from the engine, ensuring optimal temperature regulation. In fuel systems, it facilitates the transfer of fuel, contributing to the engine’s performance. For hydraulic lines, it ensures the proper operation of hydraulic systems, which are vital for various truck functions, including braking and steering 2.

Key Features of the 3957657 Elbow Hose Coupling

This Cummins part is designed with several features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding truck environments. The coupling features secure connection types that prevent leaks and maintain fluid integrity. Unique attributes such as reinforced hose ends and precise engineering contribute to its reliable operation 3.

Benefits of Using the 3957657 Elbow Hose Coupling

Utilizing this part offers several advantages. It improves fluid flow within the system by providing a smooth transition between hoses, reducing the risk of turbulence and pressure drops. The design minimizes leakage risks, ensuring a secure connection under various operating conditions. Its durability means it can withstand the rigors of commercial truck use, and its ease of installation and maintenance makes it a practical choice for fleet operations.

Installation Considerations

When installing the 3957657 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure proper function. This includes adhering to torque specifications to secure connections without overtightening, which could damage the coupling or hoses. Proper alignment of the coupling is crucial for efficient fluid flow and to prevent stress on the hoses. Compatibility with other system components should also be verified to ensure seamless integration.

Maintenance and Troubleshooting

Routine maintenance of the 3957657 Elbow Hose Coupling involves regular inspections for signs of wear, corrosion, or leaks. Common issues that may arise include connection failures or hose degradation, which can be addressed through timely replacement or repair. Troubleshooting steps for problems such as leaks involve checking connection tightness, inspecting for damage, and ensuring compatibility with system pressures and fluids.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes components and systems that enhance the performance and efficiency of commercial vehicles, underscoring the quality and dependability of the 3957657 Elbow Hose Coupling.

Conclusion

The 3957657 Elbow Hose Coupling by Cummins is a vital component in the operation of commercial trucks, contributing to the efficiency and reliability of various fluid systems. Its design and features ensure secure, leak-free connections, enhancing the performance and longevity of truck engines and systems. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part in fleet operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.