This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

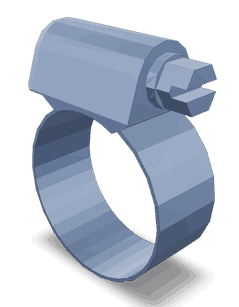

The Hose Clamp 3963720 is a specialized component manufactured by Cummins, a prominent name in the commercial vehicle industry. This hose clamp is integral to the maintenance and operation of commercial trucks, ensuring the secure connection of hoses within various systems. Cummins’ reputation for quality and innovation underscores the reliability and performance of this product.

Basic Concepts of Hose Clamps

Hose clamps are mechanical fasteners used to secure hoses to fittings, ensuring a tight and leak-free connection. They are essential in various applications, from automotive to industrial systems. Hose clamps come in several types, including worm gear, spring, and screw-type clamps, each designed for specific uses and environments. The primary function of a hose clamp is to maintain the integrity of fluid transfer systems by preventing leaks and ensuring consistent pressure 1.

Purpose of Hose Clamp 3963720

The Hose Clamp 3963720 is designed to play a specific role in the operation of commercial trucks. It secures hoses in critical systems such as the engine cooling, fuel, and hydraulic systems. This clamp is engineered to withstand the demanding environments typical of commercial truck operations, including exposure to vibrations, temperature fluctuations, and corrosive substances. By maintaining a secure connection, it helps ensure the efficient and safe operation of these systems 2.

Key Features

The Hose Clamp 3963720 features a robust design that includes high-quality materials to enhance its performance and durability. It is constructed from corrosion-resistant materials, ensuring longevity even in harsh conditions. The clamp’s design allows for easy adjustment, providing a secure fit on various hose sizes. Additionally, it incorporates a band that offers uniform pressure distribution around the hose, improving seal integrity.

Benefits of Using Hose Clamp 3963720

Employing the Hose Clamp 3963720 offers several advantages. Its design ensures improved seal integrity, reducing the risk of leaks that can lead to system failures. The ease of installation makes it a practical choice for maintenance tasks, saving time and labor. Furthermore, its durable construction contributes to long-term reliability, minimizing the need for frequent replacements.

Installation Process

To install the Hose Clamp 3963720 correctly, follow these steps:

- Ensure the hose and fitting are clean and free of debris.

- Slide the clamp onto the hose, positioning it near the fitting.

- Use the appropriate tool to tighten the clamp until it achieves a snug fit around the hose and fitting.

- Double-check the connection for any signs of leakage or uneven pressure distribution.

- Perform a system test to confirm the clamp is securely in place and functioning as intended.

Troubleshooting Common Issues

Frequent problems with hose clamps can include leaks, difficulty in tightening, and corrosion. For the Hose Clamp 3963720, potential causes might be improper installation, using the wrong size clamp, or exposure to corrosive environments. Recommended solutions include re-evaluating the installation process, ensuring the correct clamp size is used, and applying protective coatings if necessary.

Maintenance Tips

Regular inspection and maintenance are key to prolonging the lifespan of the Hose Clamp 3963720. Inspect the clamp for signs of wear, corrosion, or damage during routine maintenance checks. Clean the clamp and surrounding areas to prevent buildup that could affect performance. If any issues are detected, address them promptly to avoid more significant problems down the line.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and related components for various industries, including commercial vehicles, construction, and agriculture. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of performance and reliability.

Cummins Engine Compatibility with Hose Clamp Part 3963720

The Cummins Hose Clamp part number 3963720 is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing hoses and ensuring leak-free connections in engine systems. Below is a detailed description of its compatibility with the listed engines:

ISB/ISD Series Engines

- ISB/ISD 4.5 CM2150 B119

- ISB/ISD 6.7 CM2150 SN

The Hose Clamp part 3963720 is compatible with both the ISB/ISD 4.5 and ISB/ISD 6.7 engines. These engines are part of the Cummins B Series and are known for their reliability and efficiency. The clamp is designed to fit the specific hose configurations of these engines, ensuring a secure and reliable connection.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, including the CM2150, CM800, and CM850, also benefit from the use of the Hose Clamp part 3963720. These engines are typically used in heavy-duty applications and require robust components for maintaining system integrity. The clamp is engineered to fit the hoses used in these engines, providing a tight and durable seal.

QSB Series Engines

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, such as the QSB6.7 and QSB7, are designed for a range of applications, from industrial to agricultural use. The Hose Clamp part 3963720 is compatible with these engines, ensuring that hoses are securely fastened. This compatibility is crucial for maintaining the performance and safety of these engines in various operational environments.

By ensuring that the Hose Clamp part 3963720 fits these engines, Cummins maintains a high standard of quality and reliability across its engine lineup. This compatibility allows for easy maintenance and repair, ensuring that the engines continue to operate efficiently and safely.

Role of Part 3963720 Hose Clamp in Engine Systems

The 3963720 Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight seal around hoses, preventing leaks and ensuring consistent pressure throughout the system.

Air Compressor Inlet Kit

In the air compressor inlet kit, the 3963720 Hose Clamp is used to secure the hoses that connect the compressor to the air intake system. This ensures that the airflow is uninterrupted and that the compressor operates efficiently. The clamp helps in maintaining the integrity of the connection, which is vital for the consistent performance of the compressor.

Compressor Air Inlet Arrangement

For the compressor air inlet arrangement, the 3963720 Hose Clamp plays a significant role in securing the hoses that feed air into the compressor. This arrangement is designed to optimize airflow and reduce turbulence, which can affect the compressor’s efficiency. The clamp ensures that the hoses remain firmly in place, even under varying pressure conditions, thus maintaining a stable air supply.

Turbocharger Plumbing

In turbocharger plumbing, the 3963720 Hose Clamp is utilized to secure the hoses that connect the turbocharger to the intercooler and other components. This is essential for maintaining the pressure and temperature balance within the system. The clamp ensures that there are no leaks in the hose connections, which could lead to a loss of boost pressure and reduced turbocharger efficiency.

Overall, the 3963720 Hose Clamp is a fundamental component in these engine systems, contributing to their reliable and efficient operation by ensuring secure and leak-free connections.

Conclusion

The Hose Clamp 3963720 by Cummins is a critical component for maintaining the integrity and efficiency of various engine systems in commercial trucks. Its robust design, ease of installation, and compatibility with a range of Cummins engines make it a reliable choice for securing hoses and preventing leaks. Regular maintenance and proper installation are essential to ensure the long-term performance and safety of these systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.