This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

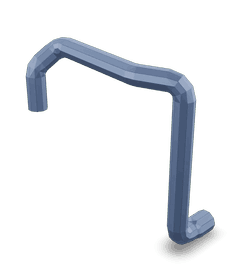

The Cummins 3972874 Molded Hose is a specialized component designed for use in commercial trucks. This hose is integral to the operation of these vehicles, facilitating the transfer of fluids between various systems. Its robust construction and precise engineering ensure reliable performance under demanding conditions, contributing to the overall efficiency and durability of the truck.

Basic Concepts of Molded Hoses

Molded hoses are manufactured through a process that involves the integration of multiple components into a single, seamless unit. This is achieved by molding the hose ends directly onto the hose body, which eliminates the need for additional clamps or fittings. Molded hoses are commonly used in automotive systems for their durability, leak resistance, and ease of installation. They are particularly valuable in applications where space is limited and secure connections are paramount 1.

Purpose of the 3972874 Molded Hose

The Cummins 3972874 Molded Hose serves a specific function within the truck’s system by connecting critical components and transporting essential fluids. It is designed to link various parts of the engine or transmission system, ensuring that fluids such as coolant, oil, or hydraulic fluid are efficiently circulated. This circulation is vital for maintaining optimal operating temperatures, lubricating moving parts, and ensuring the proper function of the transmission 2.

Key Features

The Cummins 3972874 Molded Hose boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear, corrosion, and high temperatures. The hose is designed with precision-molded ends that provide a secure and leak-free connection. Additionally, it features reinforcement layers that increase its strength and flexibility, allowing it to withstand the rigors of heavy-duty use 3.

Benefits

The Cummins 3972874 Molded Hose offers several benefits that contribute to the overall efficiency and reliability of the truck. Its robust construction and precise fit reduce the risk of leaks and ensure a consistent flow of fluids. This results in improved system performance and reduced maintenance requirements. Furthermore, the hose’s durability extends the intervals between replacements, providing long-term cost savings and enhancing the truck’s operational lifespan.

Installation

Proper installation of the Cummins 3972874 Molded Hose is crucial for ensuring its effective performance. The process involves several steps, including preparing the connection points, aligning the hose with the system components, and securing it in place. Tools such as hose crimpers may be required to achieve a proper fit. Following the manufacturer’s guidelines and best practices during installation will help prevent common issues such as leaks or improper connections.

Troubleshooting

Common issues that may arise with the Cummins 3972874 Molded Hose include leaks, blockages, or degradation over time. Troubleshooting these problems involves inspecting the hose for signs of wear, checking connection points for proper alignment, and ensuring that there are no obstructions in the fluid path. Addressing these issues promptly can prevent more serious problems and maintain the efficiency of the truck’s systems.

Maintenance

Regular maintenance of the Cummins 3972874 Molded Hose is important for ensuring its continued performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the hose and connection points to remove any buildup, and replacing the hose if it shows signs of degradation. Adhering to recommended maintenance schedules will help prevent unexpected failures and ensure the reliable operation of the truck.

Cummins Overview

Cummins is a well-established company with a long history of providing high-quality engines and components for the commercial truck industry. Known for its innovative products and commitment to customer satisfaction, Cummins offers a wide range of solutions designed to enhance the performance and reliability of commercial vehicles. The company’s reputation is built on a foundation of expertise, quality, and continuous improvement, making it a trusted name in the industry.

Cummins Molded Hose Part 3972874 Compatibility with Engine Models

The Cummins molded hose part number 3972874 is designed to fit seamlessly with a range of engine models, ensuring optimal performance and reliability. This hose is engineered to meet the specific needs of the A1400, A1700, A2000, and A2300 engines, providing a critical connection between various components within the engine system.

A1400 and A1700 Engines

For the A1400 and A1700 engines, the molded hose part 3972874 is integral to maintaining the fluid pathways necessary for efficient engine operation. This hose is typically used in applications where it needs to withstand moderate pressure and temperature variations, ensuring that the fluid flow remains uninterrupted. Its design allows for flexibility and durability, which is crucial for the longevity of these engines.

A2000 and A2300 Engines

In the A2000 and A2300 engines, the molded hose part 3972874 plays a similar role but is often subjected to more rigorous conditions due to the higher power output and performance demands of these engines. The hose is engineered to handle higher pressures and temperatures, providing a reliable connection that can endure the stresses of high-performance engine operations. Its robust construction ensures that it can maintain integrity over extended periods, contributing to the overall reliability and efficiency of these engines.

Grouping for Efficiency

When considering the A1400 and A1700 engines together, the molded hose part 3972874 is designed to fit both models with ease, thanks to their similar design and operational requirements. This commonality allows for easier inventory management and maintenance, as the same part can be used across multiple engine models, reducing costs and simplifying the supply chain.

Similarly, the A2000 and A2300 engines, while more powerful, share enough design and operational characteristics that the molded hose part 3972874 can be used interchangeably. This grouping ensures that technicians and maintenance personnel can use a single part number for both engines, streamlining the repair and replacement process.

Role of Part 3972874 Molded Hose in Radiator Systems

Part 3972874 Molded Hose is integral to the efficient operation of radiator systems in various engine setups. This component facilitates the circulation of coolant between the radiator and the engine block, ensuring optimal thermal management.

In radiator systems, the Molded Hose connects to the radiator’s inlet and outlet ports. It allows coolant to flow from the engine, where it absorbs heat, to the radiator. Here, the coolant releases heat to the surrounding air, thanks to the radiator’s fins and airflow generated by the vehicle’s movement or the cooling fan. The cooled coolant then returns to the engine via the Molded Hose, repeating the cycle.

The consistent flow of coolant maintained by the Molded Hose is essential for preventing engine overheating. It ensures that the engine operates within safe temperature ranges, thereby protecting engine components from thermal damage and extending the engine’s lifespan.

Additionally, the Molded Hose contributes to the stability of the coolant system by withstanding pressure fluctuations and temperature variations without degrading. This reliability is vital for maintaining the integrity of the cooling system under various driving conditions, from idle to high-speed operation.

In summary, the Molded Hose plays a significant role in the radiator system by enabling efficient coolant circulation, which is fundamental to engine thermal management and overall system reliability.

Conclusion

The Cummins 3972874 Molded Hose is a critical component in the operation of commercial trucks, ensuring the efficient transfer of fluids and contributing to the overall reliability and performance of the vehicle. Its robust construction, precise engineering, and compatibility with various engine models make it an essential part for maintaining the integrity of the truck’s systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term durability and cost-effectiveness.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.