This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

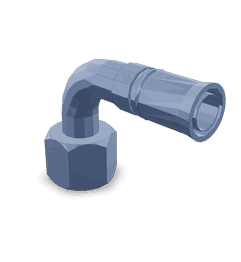

The Elbow Hose Coupling, part #4090190, manufactured by Cummins, is a component designed for use in commercial truck systems. This part contributes to the efficient operation of trucks by facilitating the transfer of various fluids within the system. Its role is significant in maintaining the overall functionality and performance of the vehicle.

Basic Concepts of Elbow Hose Couplings

Elbow hose couplings are fittings used to connect hoses at an angle, typically 90 degrees, within a truck’s fluid systems. They are integral in directing the flow of fluids such as coolant, hydraulic fluid, and brake fluid. These couplings ensure that the fluid systems operate smoothly and efficiently by providing a secure and reliable connection between hoses 1.

Purpose of the 4090190 Elbow Hose Coupling

The 4090190 Elbow Hose Coupling is designed to direct fluid flow within a truck’s system, ensuring that fluids are transported efficiently from one component to another. It plays a role in maintaining system integrity by providing a secure connection that helps to maintain pressure and flow efficiency. This part is crucial for the proper functioning of the truck’s fluid systems 2.

Key Features

The 4090190 Elbow Hose Coupling features a robust material composition that enhances its durability and performance. Its design includes attributes that ensure a secure fit and reliable operation. Unique characteristics of this coupling may include corrosion resistance and the ability to withstand high pressures, contributing to its longevity and effectiveness in demanding environments 3.

Benefits

Using the 4090190 Elbow Hose Coupling offers several benefits. It contributes to improved system reliability by ensuring secure and efficient fluid transfer. Enhanced fluid management is achieved through its design, which supports consistent pressure and flow. Additionally, this coupling plays a part in the overall performance and longevity of the truck by maintaining the integrity of the fluid systems.

Installation Considerations

When installing the 4090190 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure optimal performance. Proper alignment and a secure fitting are necessary to prevent leaks and ensure efficient fluid flow. After installation, system testing is recommended to verify that the coupling is functioning correctly and that there are no issues with the fluid system.

Troubleshooting Common Issues

Common problems associated with elbow hose couplings include leaks, blockages, and fitting failures. To diagnose these issues, it is important to inspect the coupling for signs of wear or damage. Recommended solutions may involve cleaning the coupling, tightening connections, or replacing the part if necessary. Regular maintenance practices can help prevent these issues and ensure continued efficient operation.

Maintenance Tips

Regular maintenance of the 4090190 Elbow Hose Coupling is important to ensure its continued efficient operation. Inspection schedules should be followed to check for signs of wear or damage. Cleaning procedures may be necessary to remove any buildup that could affect performance. Replacement guidelines should be consulted to determine when the coupling needs to be replaced to maintain system efficiency.

Cummins Corporation Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ reputation for producing reliable and high-performance components makes it a trusted name in the industry.

Compatibility of Elbow Hose Coupling Part 4090190 with Cummins Engines

The Elbow Hose Coupling part 4090190, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring a secure connection between hoses and engine components.

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

The G855 series engines, including the G855, G855 CM558, and GTA855 CM558 (CM2358) G101, are designed for heavy-duty applications and benefit from the precise fit of the 4090190 Elbow Hose Coupling. This part ensures that the hose connections remain tight and leak-free, which is essential for maintaining optimal engine performance.

K Series

- K38

- K50

The K38 and K50 engines, both part of the K Series, are known for their durability and efficiency. The 4090190 Elbow Hose Coupling is engineered to fit these engines perfectly, ensuring that the hose connections are robust and reliable. This is particularly important in environments where the engines are subjected to harsh conditions.

KTA19 Series

- KTA19GC

- KTA19GC CM558

The KTA19GC and KTA19GC CM558 engines are designed for a variety of applications, from marine to industrial use. The 4090190 Elbow Hose Coupling is a critical component for these engines, providing a secure and leak-proof connection that helps maintain the efficiency and longevity of the engine.

N14 Series

- N14 G

The N14 G engine is another model that benefits from the 4090190 Elbow Hose Coupling. This part ensures that the hose connections are secure, which is vital for the engine’s cooling and exhaust systems. The precise fit of this coupling helps prevent leaks and ensures that the engine operates at peak performance.

Role of Part 4090190 Elbow Hose Coupling in Engine Systems

The 4090190 Elbow Hose Coupling is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases. Its primary function is to connect and direct the flow between different sections of the system, ensuring seamless operation.

Integration with Flexible Hose

In systems utilizing flexible hoses, the 4090190 Elbow Hose Coupling serves as a pivotal connection point. It allows for the necessary flexibility and movement that the hose requires while maintaining a secure and leak-free connection. This is particularly important in dynamic environments where vibrations and movements are common, ensuring that the hose can accommodate these changes without compromising the integrity of the system.

Application in Plumbing Systems

Within plumbing systems, the 4090190 Elbow Hose Coupling is used to navigate around obstacles and change the direction of fluid flow. Its robust design ensures that it can handle the pressures and temperatures typical in these systems, providing a reliable connection that withstands the test of time and use.

Role in Turbocharger Systems

In turbocharger systems, the 4090190 Elbow Hose Coupling plays a significant role in managing the high-pressure and high-temperature environments. It connects various components, such as the intercooler and the turbocharger, allowing for efficient airflow and cooling. This ensures that the turbocharger operates within optimal parameters, enhancing overall engine performance and reliability.

Conclusion

The 4090190 Elbow Hose Coupling is a vital component in the efficient operation of commercial truck systems. Its robust design, compatibility with various Cummins engines, and role in maintaining system integrity make it an indispensable part for ensuring the performance and longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.