This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4302431 Flexible Hose is a component designed for use in commercial trucks. It serves as a conduit for various fluids within the truck’s systems, facilitating the transfer of these fluids between different parts of the vehicle. This hose is integral to maintaining the operational efficiency of the truck by ensuring that fluids reach their intended destinations without leakage or restriction.

Basic Concepts of Flexible Hoses

Flexible hoses are used in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are designed to accommodate the dynamic movements of the vehicle while maintaining a secure and leak-free connection. Within a system, flexible hoses allow for the transfer of fluids such as coolant, fuel, or hydraulic fluid, contributing to the overall functionality and reliability of the vehicle 1.

Purpose of the 4302431 Flexible Hose

The Cummins 4302431 Flexible Hose is specifically designed to connect various systems within a truck, transporting fluids that are vital for the truck’s operation. It plays a role in the fluid transfer process by providing a flexible connection that can withstand the rigors of commercial truck use, including exposure to vibrations, temperature fluctuations, and mechanical stress 2.

Key Features

The Cummins 4302431 Flexible Hose is constructed with a material composition that includes synthetic rubber and reinforcement materials to enhance its durability and flexibility. Its design incorporates features such as smooth inner walls to facilitate fluid flow and external reinforcements to resist wear and tear. These characteristics contribute to the hose’s ability to perform reliably in demanding environments 3.

Benefits

Utilizing the Cummins 4302431 Flexible Hose offers several advantages. Its flexibility allows for greater movement and vibration absorption compared to rigid hoses, which can help reduce the risk of damage from mechanical stress. The hose’s resistance to wear and tear, along with its design to minimize maintenance needs, can lead to lower overall maintenance costs and increased uptime for commercial trucks 4.

Installation Considerations

Proper installation of the Cummins 4302431 Flexible Hose is crucial for ensuring its effectiveness and longevity. Installation techniques should include the use of appropriate tools and procedures to achieve a secure fit. This may involve the use of clamps or other fastening methods to ensure that the hose is properly connected to the systems it serves, without leaks or undue stress on the hose itself 5.

Troubleshooting Common Issues

Common issues with flexible hoses, such as leaks or kinks, can often be traced back to installation errors or environmental factors. Diagnosing these problems involves a thorough inspection of the hose and its connections. Resolving issues may require re-securing connections, replacing damaged sections of the hose, or addressing external factors that contribute to wear and tear 6.

Maintenance Tips

Regular maintenance of the Cummins 4302431 Flexible Hose is key to prolonging its life and ensuring reliable operation. This includes periodic inspections for signs of wear, checking connections for tightness, and cleaning the hose to remove any buildup that could affect its performance. Adhering to a maintenance schedule can help identify potential issues before they lead to more significant problems 7.

Compatibility and Application

The Cummins 4302431 Flexible Hose is designed for specific applications within commercial trucks. Ensuring compatibility with existing truck components is important for optimal performance. This involves verifying that the hose fits within the truck’s system layout and is compatible with the fluids it will transport 8.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable components, Cummins has built a reputation for excellence in the field. Their focus on advancing technology and meeting the needs of their customers underscores their position as a leader in the industry 9.

Role of Part 4302431 Flexible Hose in Engine Systems

Plumbing Systems

In plumbing systems integrated with engine components, the 4302431 Flexible Hose serves as a vital link between various sections. It allows for the transfer of fluids such as coolant, oil, or fuel between the engine and its ancillary systems. The flexibility of the hose accommodates the natural vibrations and movements of the engine, ensuring a secure and leak-free connection. This is particularly important in high-stress environments where rigid connections could fail over time due to constant movement and thermal expansion 10.

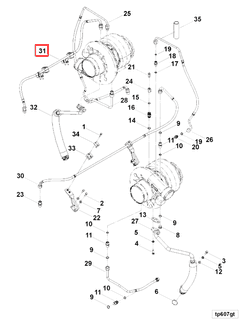

Turbocharger Systems

When incorporated into turbocharger systems, the 4302431 Flexible Hose plays a significant role in managing the flow of exhaust gases. It connects the turbocharger to the exhaust manifold, allowing for the efficient transfer of gases that drive the turbine. The flexibility of the hose is essential here as it absorbs the vibrations from the engine and the high-pressure exhaust flow, preventing stress fractures that could lead to leaks. Additionally, the hose’s material is typically resistant to high temperatures and corrosive gases, ensuring durability and reliability in demanding conditions 11.

Conclusion

The Cummins 4302431 Flexible Hose is a critical component in the efficient operation of commercial trucks. Its design and features enable it to withstand the demanding conditions of truck use, ensuring reliable fluid transfer and contributing to the overall performance and longevity of the vehicle. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing the benefits of this Cummins part.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L123B Transit Bus Applications. Bulletin Number 5411467.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L123B Transit Bus Applications. Bulletin Number 5411467.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.