This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

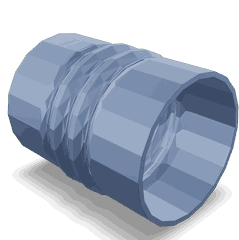

The Cummins 4324399 Oil Seal is a component designed to prevent oil leakage in commercial trucks. Its role is significant in maintaining the operational integrity of the vehicle’s engine system. By ensuring that oil remains within the designated pathways, this seal contributes to the efficient and reliable performance of the truck 1.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used to prevent leakage of lubricants where a shaft passes through a housing. In machinery, particularly in commercial trucks, oil seals play a vital role in maintaining the lubrication system’s integrity. They ensure that oil does not escape from the system, which could lead to decreased performance and potential damage to the engine components 2.

Purpose of the Cummins 4324399 Oil Seal

This Cummins part is specifically designed to function within the operational parameters of commercial trucks. It plays a role in preventing oil leakage from the engine’s rotating components, such as the crankshaft or camshaft. By maintaining the oil within the system, this seal helps in preserving the lubrication necessary for the smooth operation of these components, thereby contributing to the overall system integrity 4.

Key Features

The Cummins 4324399 Oil Seal is characterized by its robust material composition, typically featuring a combination of rubber and metal. This design allows it to withstand the high temperatures and pressures present in a truck’s engine environment. Additionally, its precise engineering ensures a snug fit around the shaft, enhancing its performance in preventing oil leakage 3.

Benefits

Utilizing this Cummins part offers several advantages. It contributes to improved engine performance by ensuring consistent lubrication. Furthermore, its durable construction promotes longevity, reducing the frequency of replacements. Reliability is another benefit, as the seal’s effective prevention of oil leakage helps maintain the engine’s operational efficiency over time 1.

Installation Process

Proper installation of the Cummins 4324399 Oil Seal is crucial for its optimal performance. The process involves cleaning the shaft and housing to remove any debris, followed by carefully placing the seal into the housing. It is important to ensure that the seal is not twisted or damaged during installation. Once in place, the seal should be checked for proper seating and alignment to guarantee effective operation 3.

Troubleshooting Common Issues

Common problems with oil seals include wear and failure, often indicated by oil leaks around the seal area. Addressing these issues may involve inspecting the seal for signs of damage, such as cracks or deformities, and replacing it if necessary. Additionally, ensuring that the shaft and housing are clean and free of debris can help prevent premature seal failure 4.

Maintenance Tips

Regular maintenance practices can prolong the life of the Cummins 4324399 Oil Seal. This includes periodic inspections for signs of wear or damage, ensuring that the seal remains properly seated, and keeping the surrounding areas clean to prevent contamination. Adhering to these practices helps in maintaining the seal’s efficiency and the overall performance of the engine lubrication system 1.

Role in Engine Lubrication System

The Cummins 4324399 Oil Seal integrates into the engine lubrication system by preventing oil from escaping around the rotating components. This ensures that the lubrication system operates efficiently, providing the necessary oil flow to critical engine parts. Its role is fundamental in maintaining the health and performance of the engine by ensuring consistent lubrication 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and transportation markets worldwide. The company’s product range is designed to meet the demanding requirements of various applications, ensuring reliability and performance 3.

Cummins Engine Oil Seal 4324399 Compatibility

The Cummins Oil Seal part number 4324399 is designed to fit seamlessly with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. This oil seal is a critical component in maintaining the integrity of the engine’s lubrication system by preventing oil leaks and ensuring that the engine operates efficiently.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the oil seal 4324399 is engineered to provide a reliable seal at various points within the engine where oil passages meet rotating shafts. This ensures that the engine’s internal components remain lubricated and protected from wear and tear.

The precision engineering of the oil seal 4324399 guarantees a perfect fit and optimal performance, making it an essential part for maintaining the longevity and reliability of these Cummins engines 3.

Role of Part 4324399 Oil Seal in Engine Systems

The part 4324399 Oil Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to prevent oil leakage and ensure that oil remains within the designated pathways, thereby supporting the lubrication and cooling processes necessary for optimal engine performance.

In the aftercooler system, the Oil Seal plays a significant role in maintaining the separation between oil and air. The aftercooler is responsible for cooling the compressed air from the turbocharger before it enters the engine’s combustion chamber. Any oil leakage could contaminate the air, leading to inefficient combustion and potential damage to engine components. The Oil Seal ensures that the oil used for lubricating the turbocharger and other moving parts does not mix with the air, thus preserving the purity of the air and the efficiency of the cooling process.

Within the hose kit assembly, the Oil Seal is integral to the hoses that carry oil to various parts of the engine. These hoses are often exposed to high temperatures and pressures, making them susceptible to wear and tear. The Oil Seal helps in maintaining a tight fit between the hose and its connection points, preventing oil from seeping out. This is particularly important in high-performance engines where even a minor oil leak can lead to significant issues, including reduced lubrication efficiency and potential engine overheating.

In the tube kit configuration, the Oil Seal is used in the tubes that transport oil to critical engine components such as the crankshaft, camshaft, and valve train. These tubes are subject to constant vibration and movement, which can loosen connections over time. The Oil Seal ensures that the tubes remain securely attached, preventing oil leaks that could lead to inadequate lubrication of these vital parts. Proper lubrication is essential for reducing friction and wear, thereby extending the lifespan of the engine components and ensuring smooth operation.

Overall, the part 4324399 Oil Seal is a fundamental component in these engine systems, playing a key role in maintaining oil integrity, ensuring efficient lubrication, and preventing contamination, all of which contribute to the reliable and prolonged operation of the engine 4.

Conclusion

The Cummins 4324399 Oil Seal is a critical component in the maintenance and efficiency of commercial truck engines. By preventing oil leakage, it ensures consistent lubrication, which is vital for the smooth operation and longevity of engine components. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the 4324399 Oil Seal, making it a reliable choice for engine lubrication systems.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ ↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ ↩ -

Cummins Inc. (n.d.). ISB CM2150 and ISB CM2150 E, Bulletin Number 4021602, Operation and Maintenance Manual.

↩ ↩ ↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.