This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

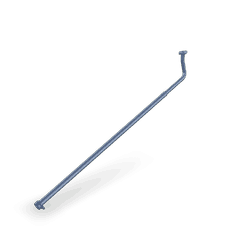

The 4917844 Flexible Hose, manufactured by Cummins, is a critical component for commercial trucks, facilitating the transfer of fluids and gases between various systems. Its design accommodates the movement and vibration typical in truck operations, ensuring reliable performance under demanding conditions 1.

Basic Concepts of Flexible Hoses

Flexible hoses are engineered to connect different parts of a vehicle’s system, enabling the transfer of fluids or gases while accommodating movement and vibration. They are constructed from layers of materials that offer strength, flexibility, and resistance to the elements they transport. Common materials include rubber, synthetic elastomers, and reinforced fabrics, chosen for their durability, flexibility, and resistance to chemicals or high temperatures 2.

Purpose of the 4917844 Flexible Hose

This Cummins part serves a specific role in truck operations by connecting various systems and facilitating the transport of fluids or gases. It is designed to withstand the pressures and temperatures associated with its application, ensuring reliable performance in demanding conditions 3.

Key Features

The 4917844 Flexible Hose features a design that balances flexibility and durability, allowing it to withstand the dynamic environment of a commercial truck. Its construction includes layers that provide strength and resistance to the fluids or gases it transports, ensuring a secure and leak-free connection. Additionally, its flexibility accommodates the movement and vibration inherent in truck operations, reducing the risk of damage or failure 4.

Benefits

Utilizing this part offers several advantages. Its flexibility reduces the risk of leaks by accommodating movement and vibration, common in truck operations. The hose’s durable construction enhances its longevity, providing reliable performance over time. Furthermore, its design allows for easier installation compared to rigid hoses, simplifying the replacement process and reducing downtime 5.

Installation Considerations

Proper installation of the 4917844 Flexible Hose is crucial for ensuring optimal performance and safety. It is important to follow guidelines and considerations for correct fitting and securing methods. This includes ensuring that connections are tight and secure, using the appropriate clamps or fittings, and verifying that the hose is not kinked or twisted, which could impede flow or cause damage 6.

Troubleshooting and Maintenance

Common issues with flexible hoses may include leaks, cracks, or reduced flexibility due to wear and tear. Troubleshooting steps may involve inspecting the hose for visible damage, checking connections for tightness, and verifying that the hose is not obstructed. Regular maintenance, including inspections for signs of wear and scheduled replacements, can help prolong the life of the 4917844 Flexible Hose and ensure continued reliable performance 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the manufacturing of automotive components. The company’s dedication to advancing technology and improving efficiency is evident in its wide range of products, including the 4917844 Flexible Hose, which is designed to meet the demanding requirements of commercial truck applications 8.

Role of Part 4917844 Flexible Hose in Engine Systems

In the context of engine systems, the 4917844 Flexible Hose is a critical component that facilitates the connection between various critical elements. Its primary function is to provide a durable and flexible link that can withstand the dynamic conditions within an engine environment.

Plumbing Systems

Within the plumbing systems of an engine, this part serves as a vital connector. It ensures that fluids, such as coolant or fuel, are efficiently transported between different parts of the engine. The flexibility of the hose allows it to accommodate the vibrations and movements inherent in engine operation, reducing the risk of leaks and maintaining system integrity 9.

Turbocharger Applications

In turbocharger setups, the 4917844 Flexible Hose plays a significant role in managing the high-pressure and high-temperature environments. It connects the turbocharger to the engine’s intake and exhaust systems, allowing for the efficient transfer of exhaust gases. This connection is essential for the turbocharger to function correctly, enhancing engine performance by increasing air intake and thus improving combustion efficiency 10.

Turbocharger Oil Systems

For turbocharger oil systems, the 4917844 Flexible Hose is used to connect the oil supply and return lines. This ensures that the turbocharger bearing is adequately lubricated, which is vital for its longevity and performance. The hose’s flexibility accommodates the turbocharger’s rotational movements, preventing oil line stress and potential failures 11.

Conclusion

The 4917844 Flexible Hose is a versatile and essential component that enhances the reliability and efficiency of engine systems by providing flexible, durable connections in various applications. Its design and construction are tailored to withstand the demanding conditions of commercial truck operations, ensuring long-term performance and reliability.

-

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.