4920417

Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hose Clamp 4920417, manufactured by Cummins, is a specialized component designed for use in commercial truck maintenance. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that are integral to the operation and maintenance of heavy-duty trucks. This Cummins part plays a significant role in ensuring the integrity of hose connections within these vehicles.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are essential in fluid systems where the secure attachment of hoses is necessary to maintain system efficiency and safety. Proper clamping is vital to prevent leaks, ensure consistent fluid flow, and protect the system from potential damage due to loose connections 1.

Purpose of Hose Clamp 4920417

This part is designed to secure specific types of hoses used in commercial trucks. It supports various systems within the truck, including but not limited to, the fuel, coolant, and hydraulic systems. By providing a secure connection, it helps maintain the efficiency and reliability of these systems, ensuring that fluids are transported without leaks or interruptions.

Key Features

The Hose Clamp 4920417 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. Its design includes elements that facilitate easy installation and adjustment, allowing for a secure fit on a variety of hose sizes. Additionally, it may feature unique characteristics such as a self-locking mechanism or a specialized band design that differentiates it from standard hose clamps.

Benefits

Utilizing the Hose Clamp 4920417 offers several advantages. It provides improved reliability of hose connections, reducing the risk of leaks and system failures. The ease of installation makes it a practical choice for maintenance and repair tasks. Furthermore, its durability under various operating conditions ensures long-term performance, contributing to the overall efficiency and safety of the commercial truck 2.

Installation Process

Installing this Cummins part correctly is crucial for its effectiveness. The process involves selecting the appropriate clamp size for the hose, positioning the clamp around the hose and fitting, and tightening it to the manufacturer’s specifications. Best practices include ensuring the clamp is evenly tightened to avoid damaging the hose and checking for any signs of leaks after installation. Common pitfalls to avoid include over-tightening, which can damage the hose, and under-tightening, which can lead to leaks 3.

Troubleshooting and Maintenance

Regular inspection and maintenance of hose clamps are necessary to ensure their continued effectiveness. Common issues such as leaks or loose connections can often be traced back to improper installation or wear and tear. Maintenance practices include periodic checks for signs of wear, ensuring clamps are properly tightened, and replacing clamps that show signs of damage or corrosion. These practices help maintain the integrity of the hose connections and the overall system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. This part, as part of Cummins’ offerings, benefits from the company’s commitment to quality and performance.

Cummins Engine Compatibility with Hose Clamp Part 4920417

This part is a versatile component designed to fit a variety of Cummins engines. It is essential for securing hoses and ensuring leak-free connections in the engine’s cooling and fuel systems. Below is a detailed description of the engines that are compatible with this hose clamp.

ISB Series Engines

- ISB4.5 CM2350 B104

- X15 CM2350 X116B

- X15 CM2350 X123B

The ISB4.5 series engines, including the X15 variants, are medium-duty diesel engines known for their reliability and efficiency. This part is designed to fit these engines, ensuring secure connections for various hoses.

ISL Series Engines

- ISL G CM2180

The ISL series engines are designed for heavy-duty applications, providing robust performance and durability. This part is compatible with the ISL G CM2180, ensuring that hoses are properly secured and maintained.

ISM and ISX Series Engines

- ISM CM570

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISM and ISX series engines are known for their high performance and efficiency. This part is compatible with a wide range of these engines, including the ISX12, ISX15, and various other variants. This ensures that hoses are securely fastened, preventing leaks and maintaining system integrity.

ISZ and QSM Series Engines

- ISZ13 CM2150 Z105

- QSM11 CM570

The ISZ and QSM series engines are designed for medium-duty applications. This part is compatible with these engines, ensuring that hoses are properly secured and maintained.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines are known for their high performance and efficiency. This part is compatible with the QSX11.9 and QSX15 variants, ensuring that hoses are securely fastened and preventing leaks.

QSZ Series Engines

- QSZ13 CM2150 Z102

The QSZ series engines are designed for medium-duty applications. This part is compatible with the QSZ13 CM2150 Z102, ensuring that hoses are properly secured and maintained.

Z14 Series Engines

- Z14 CM2670 Z103B

The Z14 series engines are designed for heavy-duty applications. This part is compatible with the Z14 CM2670 Z103B, ensuring that hoses are securely fastened and preventing leaks.

This comprehensive compatibility ensures that this part can be used across a wide range of Cummins engines, providing a reliable solution for securing hoses and maintaining system integrity.

Role of Part 4920417 Hose Clamp in Engine Systems

The 4920417 Hose Clamp is an essential component in various engine systems, ensuring secure and efficient connections across multiple arrangements and plumbing setups. Its application spans several key areas within engine operations, contributing to the overall performance and reliability of the system.

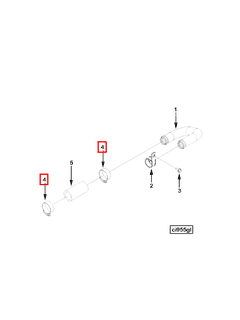

Air Compressor Kit and Compressor Air Inlet

In the air compressor kit, the 4920417 Hose Clamp is utilized to secure the hoses that connect to the compressor air inlet. This ensures a tight seal, preventing air leaks that could reduce the efficiency of the compressor. The clamp’s role is to maintain consistent air pressure within the system, which is vital for the compressor’s performance.

Crankcase Breather and Turbocharger Arrangements

For the crankcase breather arrangement, the hose clamp secures the breather hoses, allowing for the safe release of pressure from the crankcase. This is important for maintaining engine health by preventing the buildup of harmful gases. In turbocharger arrangements, the clamp ensures that the turbocharger’s air inlet and exhaust connections are secure, which is essential for optimal turbocharger performance and durability.

CPR Air Inlet and Breather

The CPR (Compressor Pressure Relief) air inlet and breather system also benefit from the use of the 4920417 Hose Clamp. By securing the hoses in these systems, the clamp helps maintain the integrity of the pressure relief mechanism, ensuring that the compressor operates within safe parameters.

Compressor, Air, and Package Product Installation

During the installation of compressor, air, and package products, the hose clamp plays a significant role in securing various hose connections. This is particularly important in ensuring that all components are installed correctly and that the system operates efficiently from the outset.

Plumbing Connections

In plumbing applications such as compressor air inlet plumbing, exhaust recirculation water plumbing, turbocharger plumbing, and turbocharger oil plumbing, the 4920417 Hose Clamp is instrumental. It secures connections to the turbocharger oil drain and ensures that all fluid pathways are sealed properly. This is essential for preventing leaks and maintaining the correct flow of fluids, which is critical for the engine’s lubrication and cooling systems.

Overall, the 4920417 Hose Clamp is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure and leak-free connections.

Conclusion

The Hose Clamp 4920417 by Cummins is a critical component in the maintenance and operation of commercial trucks. Its role in securing hose connections across various engine systems ensures the efficiency, reliability, and safety of these vehicles. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engines are essential for maximizing the benefits of this part. By utilizing the Hose Clamp 4920417, technicians and fleet managers can ensure that their trucks operate at peak performance, with minimal risk of leaks or system failures.

-

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

James D. Halderman, Automotive Principles: Diagnosis and Service, Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.