This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

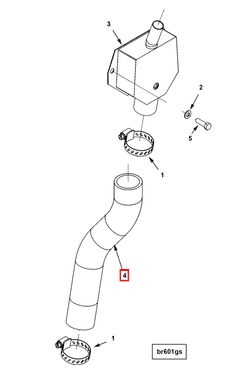

The 4924673 Molded Hose is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This hose is specifically designed for use in commercial trucks, where it plays a role in various systems. Cummins is renowned for its commitment to quality and innovation, ensuring that their products meet the demanding requirements of commercial vehicle applications 1.

Purpose and Function

This Cummins part serves a role in the operation of commercial trucks. It is utilized in systems where fluid transfer is necessary, such as coolant, fuel, and hydraulic systems. The hose facilitates the movement of these fluids under varying pressure conditions, contributing to the overall efficiency and reliability of the truck’s systems. Its design allows it to withstand the harsh environments typically encountered in commercial trucking, ensuring consistent performance 2.

Key Features

The 4924673 is constructed with high-quality materials that enhance its durability and performance. It features a robust design that includes reinforced ends to prevent leaks and ensure a secure fit within the truck’s system. The hose is made from materials that resist degradation from exposure to chemicals, oils, and extreme temperatures, which are common in commercial truck applications. Additionally, its molded construction provides a seamless fit, reducing the risk of failure points that can occur with traditional hose assemblies 3.

Benefits

Utilizing this part offers several advantages. Its high-quality construction leads to improved efficiency within the truck’s systems, as it maintains consistent fluid flow under pressure. The hose’s durability contributes to its reliability, reducing the frequency of replacements and maintenance. Furthermore, its design enhances longevity, providing a cost-effective solution for commercial truck operators.

Installation

Proper installation of the Molded Hose is crucial for ensuring its optimal performance. It is recommended to follow manufacturer guidelines for installation, which may include specific tools or equipment. The process typically involves preparing the hose and connection points, ensuring a clean and dry surface for attachment. Careful attention to the manufacturer’s instructions will help achieve a secure and leak-free installation.

Maintenance and Troubleshooting

Routine maintenance of the 4924673 is important for ensuring its continued performance. Regular inspections should be conducted to check for signs of wear, leaks, or damage. Common issues may include cracks in the hose or deterioration of the connection points. Troubleshooting advice often involves checking for proper installation and ensuring that all connection points are secure. Addressing issues promptly can prevent more significant problems down the line.

Safety Considerations

When working with the Molded Hose, it is important to adhere to safety guidelines. This includes wearing appropriate personal protective equipment during installation and maintenance. Additionally, ensuring that the truck’s systems are depressurized before beginning work can prevent accidents. Following manufacturer recommendations for handling and disposal is also crucial for maintaining a safe working environment.

Environmental Impact

The 4924673 is designed with consideration for its environmental impact. The materials used in its construction are chosen for their durability and resistance to degradation, reducing the need for frequent replacements. Disposal practices should follow local regulations to minimize environmental harm. Cummins is committed to reducing the environmental footprint of its products, including through the use of eco-friendly materials where possible.

Cummins Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and quality. The company has built a reputation for producing reliable and high-performance components, including the 4924673. Cummins’ commitment to quality is evident in their rigorous testing and quality control processes, ensuring that their products meet the high standards required for commercial vehicle applications.

Cummins Engine Compatibility with Molded Hose Part 4924673

The Cummins molded hose part 4924673 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This hose is engineered to meet the specific needs of the engines it supports, providing a durable and efficient solution for fluid transfer and management.

QSK38 CM2150 MCRS and QSK50 CM2150 K107

The molded hose part 4924673 is compatible with the QSK38 CM2150 MCRS and QSK50 CM2150 K107 engines. These engines are part of the Cummins QSK series, known for their robust design and high performance. The hose is engineered to fit precisely within the engine’s fluid systems, ensuring that it can handle the demands of these powerful engines without compromising on durability or efficiency.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

The molded hose part 4924673 also fits the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines are part of the Cummins QSK series, which is renowned for its reliability and efficiency. The hose is designed to integrate smoothly with the fluid systems of these engines, providing a reliable connection that can withstand the rigors of heavy-duty operations.

The compatibility of the molded hose part 4924673 with these engines ensures that it can effectively manage fluid transfer and pressure within the engine systems. This compatibility is crucial for maintaining the performance and longevity of the engines, as it ensures that the hose can handle the specific requirements of each engine model.

Role of Part 4924673 Molded Hose in Engine Systems

The 4924673 Molded Hose is an integral component in various engine systems, facilitating the efficient operation of several key elements.

Breather System Integration

In the breather system, the 4924673 connects the breather to the crankcase. This connection allows for the release of pressure build-up within the crankcase, ensuring that the engine operates smoothly. The hose’s durable construction prevents leaks, maintaining the integrity of the breather system and contributing to overall engine performance.

Crankcase Ventilation

The hose plays a role in the crankcase ventilation process. By providing a secure pathway for gases to escape, it helps in reducing the accumulation of harmful byproducts within the crankcase. This not only enhances engine efficiency but also prolongs the lifespan of the engine components by minimizing exposure to corrosive substances.

Breather Kit Functionality

When incorporated into a breather kit, the 4924673 ensures that all components within the kit function cohesively. It allows for the proper circulation of air and gases, which is essential for the kit’s effectiveness in maintaining optimal engine conditions. The hose’s reliable performance under varying engine loads and temperatures makes it a valuable asset in any breather kit configuration.

Conclusion

The 4924673 Molded Hose by Cummins is a critical component for commercial trucks, offering durability, efficiency, and reliability in fluid transfer systems. Its compatibility with various Cummins engines ensures optimal performance and longevity. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 4924673, making it a valuable asset for commercial truck operators.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.