This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

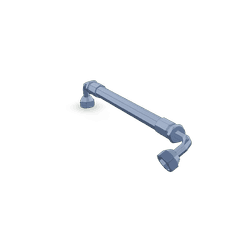

The Cummins 4964200 Flexible Hose is a component designed for use in heavy-duty truck systems. It serves as a conduit for various fluids within the truck’s operational systems, facilitating the transfer of these fluids between different parts of the vehicle. This hose is integral to maintaining the efficiency and reliability of the truck’s systems.

Basic Concepts of Flexible Hoses

Flexible hoses are used in automotive systems to connect rigid pipes and components, allowing for movement and vibration without compromising the flow of fluids. They are typically made from materials that can withstand the pressure and temperature of the fluids they transport, as well as the physical stresses of the vehicle’s operation. Flexible hoses function by providing a flexible connection that can accommodate the dynamic movements of a vehicle, ensuring a continuous and secure fluid transfer 1.

Purpose of the Cummins 4964200 Flexible Hose

The Cummins 4964200 Flexible Hose is specifically designed to connect various systems within a heavy-duty truck, transporting fluids such as coolant, fuel, or hydraulic fluid. It plays a role in ensuring that these fluids are delivered efficiently and under the correct pressure to the components that require them, contributing to the overall performance and reliability of the truck 2.

Key Features

The Cummins 4964200 Flexible Hose is characterized by its material composition, which typically includes synthetic rubber or other durable polymers. These materials are chosen for their resistance to the chemicals in the transported fluids, as well as their ability to withstand high temperatures and pressures. The hose’s design may include reinforcement layers to enhance its durability and prevent kinking or collapse under pressure. Additionally, the hose is engineered to be flexible enough to accommodate the movements of the truck without compromising its integrity 3.

Benefits

Using the Cummins 4964200 Flexible Hose offers several advantages. Its flexibility allows it to adapt to the movements of the truck, reducing the risk of leaks or damage. The hose’s resistance to wear and tear, along with its durability, contributes to the safety and efficiency of truck operations. Furthermore, its design helps to minimize the risk of fluid leaks, which can be hazardous and lead to system failures.

Installation Considerations

When installing the Cummins 4964200 Flexible Hose, it is important to ensure compatibility with the specific truck model and system it will be used in. Proper installation involves securing the hose with the appropriate clamps and ensuring a snug fit to prevent leaks. It is also crucial to follow the manufacturer’s guidelines for installation to ensure the hose operates within its designed parameters and maintains its integrity over time.

Troubleshooting and Maintenance

Common issues with flexible hoses include leaks, kinks, and degradation over time. Regular inspection for signs of wear, such as cracks or softening of the material, is important for maintaining the hose’s performance. If a leak is detected, it may be necessary to replace the hose or repair the connection. Keeping the hose clean and free from debris can also help prolong its lifespan.

Safety Precautions

When handling, installing, or maintaining the Cummins 4964200 Flexible Hose, it is important to observe safety measures to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following all manufacturer guidelines for safe handling and installation.

Environmental Impact

The production, use, and disposal of the Cummins 4964200 Flexible Hose have environmental considerations. Efforts to minimize the environmental footprint may include using recyclable materials in the hose’s construction, designing for longevity to reduce the frequency of replacements, and providing guidelines for proper disposal or recycling at the end of the hose’s life cycle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations.

Cummins Engine Compatibility with Part 4964200

The Cummins part 4964200, a Flexible Hose, is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to fit specific models within the QSK50 series, including the CM2150 MCRS, CM2350 K108, and CM850 MCRS engines.

QSK50 Series Engines

QSK50 CM2150 MCRS and QSK50 CM2350 K108

The Flexible Hose part 4964200 is compatible with the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines are part of the QSK50 series, known for their robust design and high performance in various industrial applications. The hose is engineered to connect critical components within these engines, ensuring efficient fluid transfer and maintaining the integrity of the engine’s cooling and lubrication systems.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine also benefits from the use of the Flexible Hose part 4964200. This engine, part of the QSK60 series, is designed for heavy-duty applications, requiring reliable and durable components. The hose is specifically designed to fit the unique layout and requirements of the CM850 MCRS engine, ensuring that it can withstand the rigors of demanding environments.

Integration and Functionality

The Flexible Hose part 4964200 is designed to provide flexibility and durability, allowing it to connect various engine components without compromising performance. Its compatibility with the QSK50 and QSK60 series engines ensures that it can handle the specific demands of these engines, whether in marine, industrial, or power generation applications. The hose’s design allows for easy installation and maintenance, contributing to the overall efficiency and longevity of the engine.

Role of Part 4964200 Flexible Hose in Engine Systems

The part 4964200 Flexible Hose is a vital component in various engine systems, facilitating the efficient transfer of fluids between different parts of the engine. Its primary function is to connect the pump to the fuel system, ensuring a seamless flow of fuel from the pump to the engine’s combustion chamber.

In the fuel system, the flexible hose plays a significant role in maintaining the integrity of the fuel line. It accommodates the natural vibrations and movements of the engine, preventing stress and potential damage to the fuel lines. This flexibility is particularly important in high-performance engines where vibrations are more pronounced.

Additionally, the flexible hose acts as a buffer, absorbing any shocks or pulsations generated by the pump. This helps in stabilizing the fuel flow, ensuring a consistent supply to the engine. The hose’s design also allows for easier installation and maintenance, as it can be routed around obstacles within the engine compartment without the need for rigid bends.

Furthermore, the use of a flexible hose in the fuel system enhances safety by reducing the risk of fuel leaks. Its material is typically resistant to fuel and other chemicals, ensuring durability and reliability over time. The hose also contributes to the overall efficiency of the fuel system by minimizing pressure drops and ensuring that the fuel reaches the engine under optimal conditions.

Conclusion

The Cummins 4964200 Flexible Hose is a critical component in heavy-duty truck systems, designed to ensure the efficient and reliable transfer of fluids within the vehicle. Its flexibility, durability, and compatibility with specific Cummins engines make it an indispensable part of modern engine designs. Proper installation, maintenance, and adherence to safety precautions are essential to maximize the performance and longevity of this Cummins part.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.