This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

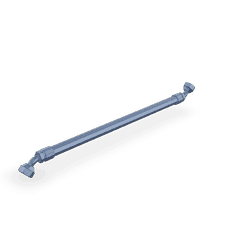

The Cummins 4967317 Flexible Hose is a component designed for use in commercial truck operations. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in various automotive systems to transport fluids between different parts of the vehicle. They are designed to accommodate movement and vibration, which are common in the dynamic environment of a truck. Flexible hoses play a role in connecting rigid pipes and components, allowing for fluid transfer without the risk of leaks or damage due to the vehicle’s motion 1.

Purpose of the 4967317 Flexible Hose

The Cummins 4967317 Flexible Hose is engineered to connect specific systems within a truck, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid. Its role is to ensure a secure and leak-free connection between components, which may be subject to movement or vibration. This hose contributes to the efficient operation of the truck by maintaining the integrity of the fluid transfer system 2.

Key Features

The 4967317 Flexible Hose is characterized by several features that enhance its performance and durability. It is constructed from materials that offer resistance to the specific fluids it transports, as well as to the environmental conditions it may encounter. The design of the hose includes reinforced ends to ensure a secure fit with connecting components, and it may incorporate additional elements such as protective coatings or layers to further improve its resilience 3.

Benefits

Utilizing the Cummins 4967317 Flexible Hose offers several advantages. Its flexibility allows it to adapt to the movements of the truck, reducing the likelihood of damage or disconnection. The hose’s resistance to wear and tear contributes to its longevity, and its design enhances the safety and efficiency of fluid transfer within the truck’s systems.

Installation Considerations

When installing the 4967317 Flexible Hose, it is important to follow guidelines and best practices to ensure compatibility with other components and to maintain the integrity of the system. Proper installation involves checking for the correct fit with connecting parts, ensuring that all connections are secure, and verifying that the hose is routed in a manner that avoids abrasion or kinking.

Troubleshooting and Maintenance

Common issues with flexible hoses may include leaks, cracks, or blockages. Regular inspection and maintenance can help identify problems early, allowing for timely repairs or replacements. Maintenance tips for the 4967317 Flexible Hose include checking for signs of wear, ensuring connections remain tight, and protecting the hose from sharp edges or excessive heat.

Safety Protocols

When handling, installing, or maintaining the 4967317 Flexible Hose, it is important to adhere to safety measures and protocols. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and the engine is off during installation or maintenance, and following manufacturer guidelines to prevent accidents and ensure compliance with industry standards.

Environmental Impact

The use and disposal of the Cummins 4967317 Flexible Hose should be considered in the context of environmental impact. Efforts to minimize waste and promote recycling can be part of a sustainable approach to managing automotive components. Any eco-friendly features of the hose, such as recyclable materials or reduced environmental footprint during manufacturing, should be taken into account.

Cummins Overview

Cummins Inc. is a company with a history of innovation and quality in the automotive industry. It offers a wide range of products designed to meet the needs of commercial and industrial applications. Cummins is committed to advancing technology and providing reliable solutions for its customers, reflecting its dedication to excellence and customer satisfaction.

Cummins Flexible Hose 4967317 Compatibility

The Cummins Flexible Hose part number 4967317 is designed to fit seamlessly within a variety of Cummins engine models. This hose is engineered to provide a reliable connection in applications where flexibility and durability are paramount.

QSK60 and CM850 Engines

The QSK60 and CM850 engines are both high-performance diesel engines, often utilized in demanding industrial and marine applications. The flexible hose 4967317 is specifically engineered to interface with the intricate systems within these engines, ensuring efficient fluid transfer and minimizing the risk of leaks or failures.

MCRS Engines

The MCRS engines, known for their robust design and reliability, also benefit from the use of the Cummins Flexible Hose 4967317. This hose is tailored to meet the stringent requirements of MCRS engines, providing a critical connection point that maintains system integrity under varying operational conditions.

General Application

Across these engines, the flexible hose 4967317 is a vital component that ensures the smooth operation of the engine’s fluid systems. Its design allows for movement and flexibility, accommodating the natural shifts and vibrations that occur during engine operation. This feature is particularly important in high-stress environments where rigid connections could lead to failure.

The hose’s construction materials and engineering ensure it can withstand the pressures and temperatures typical of these engines, providing a long-lasting solution for maintaining system efficiency and reliability.

Role of Part 4967317 Flexible Hose in Engine Systems

The part 4967317 Flexible Hose is an essential component in various engine systems, facilitating the transfer of fluids between different parts of the engine. Its primary function is to connect the fuel filter to the fuel system, ensuring a secure and leak-free passage for fuel.

In the fuel system, the flexible hose allows for the movement and vibration that occur during engine operation without compromising the integrity of the fuel line. This flexibility is vital for maintaining a consistent fuel flow to the engine, which is necessary for optimal performance and efficiency.

Additionally, the hose plays a significant role in the filtration process. By connecting the fuel filter to the fuel lines, it ensures that the fuel passing through is clean and free from contaminants. This clean fuel is then delivered to the engine, contributing to the overall efficiency and longevity of the engine components.

The design of the 4967317 Flexible Hose also accommodates thermal expansion and contraction, which are common in engine environments due to varying temperatures. This adaptability helps in preventing stress on the connections and reduces the risk of leaks or failures over time.

Overall, the 4967317 Flexible Hose is a key component in ensuring the smooth and efficient operation of the fuel system within engine applications.

Conclusion

The Cummins 4967317 Flexible Hose is a critical component in the efficient and reliable operation of commercial trucks and industrial engines. Its design, featuring flexibility, durability, and resistance to environmental conditions, ensures secure and leak-free fluid transfer. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the performance and longevity of this part. Additionally, considering the environmental impact of its use and disposal aligns with sustainable practices in the automotive industry.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.