This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

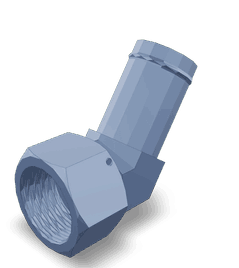

The 5266603 Elbow Hose Coupling is a component manufactured by Cummins, designed for use in commercial trucks. This coupling facilitates the connection between hoses in fluid systems, ensuring efficient and reliable operation. Cummins, a well-established manufacturer in the automotive and industrial sectors, produces this part to meet the demanding requirements of heavy-duty applications 4.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees. It allows for flexible routing of fluids within a system, accommodating space constraints and enhancing the overall design of fluid pathways. These couplings are commonly employed in automotive and industrial settings to connect hoses in systems that transport fluids such as coolant, fuel, or hydraulic fluid 1.

Purpose of the 5266603 Elbow Hose Coupling

The 5266603 Elbow Hose Coupling plays a specific role in the operation of a truck by enabling the connection of hoses within the truck’s fluid systems at an angle. This design helps manage the routing of fluids, ensuring that connections are secure and that fluid flow is maintained efficiently. Its function is vital for the proper operation of systems that rely on consistent fluid transfer, such as cooling or hydraulic systems 2.

Key Features

The 5266603 Elbow Hose Coupling is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The design includes precise fitting mechanisms that provide a secure connection between hoses, minimizing the risk of leaks. Additionally, the coupling is engineered to withstand high pressure and temperature variations commonly encountered in commercial truck applications 3.

Benefits

The 5266603 Elbow Hose Coupling offers several benefits that contribute to the efficient operation of a truck’s fluid systems. Improved fluid flow is achieved through its design, which minimizes restrictions and ensures smooth transit of fluids. Enhanced system reliability is another advantage, as the secure connections provided by the coupling reduce the likelihood of leaks or failures. Fleet operators may also experience potential cost savings due to the coupling’s durability and reduced maintenance requirements.

Installation Considerations

When installing the 5266603 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure proper integration within the system. Compatibility with other system components should be verified to avoid issues such as leaks or improper fit. Necessary tools and equipment, such as wrenches and hose cutters, should be on hand to facilitate a smooth installation process. Careful attention to manufacturer recommendations will help achieve optimal performance and longevity of the coupling.

Troubleshooting Common Issues

Common problems associated with elbow hose couplings include leaks and blockages. To address these issues effectively, it is important to conduct regular inspections and maintenance. If a leak is detected, the coupling should be examined for signs of wear or damage, and replaced if necessary. Blockages can often be resolved by cleaning the coupling and ensuring that hoses are properly aligned and connected.

Maintenance Tips

Regular maintenance of the 5266603 Elbow Hose Coupling is recommended to ensure long-term performance and reliability. Inspection intervals should be established to check for signs of wear, corrosion, or damage. Cleaning procedures, such as flushing the coupling with a compatible fluid, can help remove debris and maintain optimal flow conditions. Adhering to these maintenance practices will contribute to the overall efficiency and durability of the truck’s fluid systems.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer with a rich history in the automotive and industrial sectors. The company offers a diverse product range that includes engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins is recognized for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry 4.

Engine Compatibility with Elbow Hose Coupling Part 5266603

The Elbow Hose Coupling part number 5266603, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is crucial for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems.

Compatibility with ISC Series Engines

The ISC series engines, including the ISC CM2150, ISC CM850, and ISC8.3 CM2250, are well-suited for the 5266603 Elbow Hose Coupling. This part is engineered to fit the specific design and requirements of these engines, ensuring a secure and reliable connection for hoses that transport fluids such as coolant and exhaust gases.

Compatibility with ISL Series Engines

The ISL series engines, which include the ISL CM2150, ISL G CM2180, ISL9 CM2150 SN, and ISL9 CM2250, also benefit from the use of the 5266603 Elbow Hose Coupling. This part is designed to integrate smoothly with the ISL engines, providing a robust connection that can withstand the rigors of engine operation.

Compatibility with C Series Engines

The C series engines, such as the C GAS PLUS CM556, C8.3 G, and 6C8.3, are compatible with the 5266603 Elbow Hose Coupling. This part is tailored to fit the unique design of these engines, ensuring that hoses are securely attached and fluid flow is maintained efficiently.

By using the 5266603 Elbow Hose Coupling, engine operators can ensure that their systems are well-maintained and functioning optimally. This part is a critical component in the overall performance and longevity of the engines it is designed to fit.

Role of Part 5266603 Elbow Hose Coupling in Engine Systems

The part 5266603 Elbow Hose Coupling is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases between different parts of the engine. Its role can be observed in the following components:

Alternator Drive Arrangement

In the alternator drive arrangement, the Elbow Hose Coupling ensures a secure and flexible connection between the alternator and the engine. This allows for the smooth transmission of power from the engine to the alternator, enabling the alternator to generate electricity efficiently. The coupling’s design accommodates the necessary movement and vibration, maintaining a reliable connection despite the dynamic environment of the engine compartment.

Oil Fill and Cover System

Within the oil fill and cover system, the Elbow Hose Coupling plays a part in directing oil flow to and from the cylinder block. It connects the oil fill port to the engine’s lubrication system, ensuring that oil is distributed evenly to critical moving parts. This helps in reducing friction and wear, contributing to the longevity and performance of the engine.

Cylinder Block and Cover

The cylinder block and cover assembly benefits from the Elbow Hose Coupling by maintaining a consistent flow of coolant or other fluids. This coupling connects various hoses that run to and from the cylinder block, ensuring that the engine remains at an optimal operating temperature. Proper fluid circulation prevents overheating and enhances the engine’s efficiency and reliability.

Hand Hole and Drive Components

In systems where hand holes are present for maintenance access, the Elbow Hose Coupling might be used to connect diagnostic or maintenance hoses. This allows mechanics to check fluid levels, pressures, and perform other necessary inspections without dismantling the engine. Additionally, in drive components, the coupling ensures that any fluid-driven systems, such as hydraulic or pneumatic systems, operate smoothly and without leaks.

Alternator Mounting

The Elbow Hose Coupling also assists in the alternator mounting system by providing a flexible connection between the alternator and its fluid lines. This is particularly important in systems where the alternator is subject to movement or vibration, as the coupling absorbs these forces, preventing damage to the hoses and ensuring a stable connection.

Conclusion

In summary, the 5266603 Elbow Hose Coupling is integral to the functioning of various engine systems, providing flexibility, reliability, and efficient fluid transfer across different components. Its design and features ensure secure connections, enhanced system reliability, and long-term durability, making it a critical component for the maintenance and optimal performance of commercial truck engines.

-

Modern Diesel Technology Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Delmar Cengage Learning, 2014

↩ -

The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Giancarlo Genta and Lorenzo Morello, Springer, 2019

↩ -

Electrical Systems and Mechatronics, Second Edition, Michael Hilgers, Springer Vieweg, 2023

↩ -

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.