This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

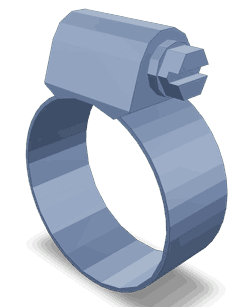

The Cummins 5280768 Hose Clamp is a specialized component designed for use in commercial trucks. Its purpose is to secure and seal hoses within various truck systems, ensuring efficient operation and maintenance. This clamp is integral to maintaining the integrity of fluid transfer systems, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Hose Clamps

Hose clamps are devices used to create a secure connection between a hose and a fitting. They function by compressing the hose against the fitting, thereby creating a seal that prevents leaks. There are several types of hose clamps, including worm-drive, spring, and screw-type clamps, each suited to different applications based on the required clamping force and environmental conditions 1.

Purpose of the Cummins 5280768 Hose Clamp

The Cummins 5280768 Hose Clamp is specifically designed to be used in various truck systems such as fuel, coolant, and air intake. It plays a role in these systems by ensuring that hoses remain securely attached to their fittings, which helps maintain the integrity of the fluid pathways. This is particularly important in environments where vibrations and temperature fluctuations are common, as these factors can loosen connections and lead to leaks 2.

Key Features

The Cummins 5280768 Hose Clamp is constructed with high-quality materials to ensure durability and performance. Its design includes a robust band material that provides the necessary clamping force to secure hoses effectively. Additionally, the clamp may feature unique characteristics such as corrosion-resistant coatings or ergonomic handles for ease of installation.

Benefits

Using the Cummins 5280768 Hose Clamp offers several advantages. It provides improved seal integrity, which is crucial for preventing leaks in fluid transfer systems. The clamp is also designed for ease of installation, reducing the time and effort required during maintenance procedures. Furthermore, its resistance to corrosion and wear ensures longevity, even in harsh operating conditions 3.

Installation Process

To install the Cummins 5280768 Hose Clamp, first, ensure that the hose and fitting are clean and free of debris. Position the clamp around the hose and fitting, then use the appropriate tool to tighten it until the desired clamping force is achieved. It is important to follow best practices, such as not over-tightening the clamp, to avoid damaging the hose or fitting.

Troubleshooting and Maintenance

Common issues with hose clamps include leaks due to improper installation or wear over time. To diagnose problems, inspect the clamp for signs of corrosion, damage, or looseness. Regular maintenance, such as checking the clamp’s condition and ensuring it remains securely tightened, can help prolong its life and prevent issues.

Compatibility and Applications

The Cummins 5280768 Hose Clamp is designed for use in various truck systems, compatible with different hose sizes and materials. It is important to verify compatibility to ensure optimal performance and reliability in specific applications.

Safety Considerations

When installing or maintaining the Cummins 5280768 Hose Clamp, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the truck is parked on a level surface, and following all manufacturer recommendations to prevent accidents and ensure proper function.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets, providing reliable and efficient solutions for a wide range of applications 4.

Cummins Hose Clamp 5280768 Compatibility with Engine Models

The Cummins Hose Clamp 5280768 is designed to ensure secure and leak-proof connections in various engine systems. This part is engineered to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability.

QSK60 and CM850 Engines

The QSK60 and CM850 engines are part of Cummins’ heavy-duty engine lineup, known for their robust performance and durability. The Hose Clamp 5280768 is specifically designed to integrate with these engines, providing a reliable seal for high-pressure fluid and gas lines. This ensures that the engines maintain their operational integrity, preventing leaks that could lead to performance degradation or safety hazards.

MCRS Engines

The MCRS engines, another segment of Cummins’ extensive engine portfolio, also benefit from the Hose Clamp 5280768. This part is engineered to fit the unique design and requirements of the MCRS engines, ensuring that all fluid and gas lines are securely fastened. This compatibility is crucial for maintaining the efficiency and longevity of the MCRS engines, as it prevents any potential leaks that could compromise engine performance.

Grouping for Efficiency

When considering the QSK60, CM850, and MCRS engines together, it is evident that the Hose Clamp 5280768 is a versatile component. Its design allows it to be used across these engines, simplifying maintenance and repair processes. This compatibility ensures that technicians and operators can use a single part across multiple engine models, reducing inventory costs and simplifying supply chain management.

By ensuring that the Hose Clamp 5280768 fits seamlessly with the QSK60, CM850, and MCRS engines, Cummins maintains a high standard of quality and reliability in its engine components. This compatibility is a testament to Cummins’ commitment to providing durable and efficient solutions for its customers.

Role of Part 5280768 Hose Clamp in Engine Systems

The part 5280768 Hose Clamp is a critical component in the secure and efficient operation of various engine systems. Its primary function is to ensure a tight and reliable connection between hoses and their respective fittings, which is vital for the proper functioning of fluid-based systems within an engine.

In the engine cooling system, the Hose Clamp plays a significant role by securing the hoses that circulate coolant through the engine block and radiator. This ensures that the coolant flow is uninterrupted, which is necessary for maintaining optimal engine temperature and preventing overheating. The clamp’s ability to withstand high temperatures and resist corrosion contributes to the longevity and reliability of the cooling system.

Within the crankcase breather system, the Hose Clamp is used to connect the breather hoses, which allow for the release of pressure and contaminants from the crankcase. A secure connection here is important to prevent leaks and ensure that the breather system functions correctly, maintaining clean oil and efficient engine operation.

The Hose Clamp also finds its application in the arrangement of various engine components. For instance, in systems where hoses are used to route fluids to different parts of the engine, such as fuel lines or hydraulic systems, the clamp ensures that these connections remain intact under varying conditions of pressure and temperature.

Additionally, in systems involving a resistor or other electrical components where cooling is required, the Hose Clamp secures the hoses that may be part of a secondary cooling loop. This helps in dissipating heat away from sensitive electrical parts, ensuring they operate within their specified temperature ranges.

Overall, the consistent and reliable performance of the Hose Clamp across these systems underscores its importance in maintaining the integrity and efficiency of engine operations.

Conclusion

The Cummins 5280768 Hose Clamp is a vital component in ensuring the secure and efficient operation of various engine systems. Its role in maintaining the integrity of fluid pathways, preventing leaks, and ensuring optimal engine performance makes it an indispensable part of commercial truck maintenance. By understanding its features, benefits, and proper installation, technicians can ensure the longevity and reliability of this Cummins part in demanding environments.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.