This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

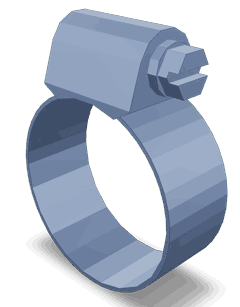

The 5287716 Hose Clamp, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is significant in maintaining the integrity of various hose systems within these vehicles, ensuring they function correctly under demanding conditions.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are vital in the automotive industry, particularly in commercial trucks, where they are employed in various systems including fuel, coolant, and pneumatic systems. Hose clamps come in several types, such as worm gear, spring, and wire clamps, each suited to different applications based on the specific requirements of the system they serve 1.

Purpose of Hose Clamp 5287716 in Truck Operations

This part plays a role in securing hoses in commercial trucks, facilitating the operation of critical systems. It is utilized in fuel systems to maintain the integrity of fuel lines, in coolant systems to ensure proper circulation of coolant, and in pneumatic systems to secure air lines. Its application across these systems underscores its importance in maintaining the overall functionality and safety of the vehicle.

Key Features of Hose Clamp 5287716

The 5287716 is characterized by its robust design and material composition. Constructed from high-quality materials, it is built to withstand the rigors of commercial truck operations. Its size is tailored to fit specific hose diameters, ensuring a secure fit. Unique attributes such as corrosion resistance and durability enhance its performance, making it suitable for long-term use in demanding environments 2.

Benefits of Using Hose Clamp 5287716

Employing this Cummins part in truck maintenance and repair offers several advantages. Its design allows for ease of installation, reducing downtime during maintenance procedures. The clamp’s reliability ensures consistent performance, minimizing the risk of leaks or failures. Additionally, its resistance to environmental factors such as moisture and temperature fluctuations contributes to its longevity and effectiveness in various operating conditions 3.

Installation and Usage Guidelines

Proper installation of the 5287716 involves several steps to ensure a secure fit. Begin by cleaning the hose and fitting to remove any debris. Slide the clamp onto the hose, ensuring it is positioned correctly. Use the appropriate tool to tighten the clamp, applying even pressure to avoid damaging the hose. Best practices include checking the clamp periodically for tightness and making adjustments as necessary to maintain a secure connection.

Troubleshooting Common Issues

Frequent problems with hose clamps, such as leaks or improper sealing, can often be traced to incorrect installation or wear and tear. To address these issues, first, ensure the clamp is correctly positioned and tightened. If leaks persist, inspect the hose and fitting for damage. In cases of wear, replacing the clamp or hose may be necessary to restore proper function.

Maintenance Tips

Regular inspection and maintenance of the 5287716 are crucial for ensuring its longevity and consistent performance. Check for signs of wear, such as cracks or corrosion, and replace the clamp if necessary. Additionally, ensure the clamp remains securely tightened, as loosening over time can lead to leaks or failures. Adhering to these maintenance practices will help maintain the integrity of the hose systems in commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. Its commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in the field.

Cummins Hose Clamp 5287716 Compatibility with Engine Models

The 5287716 is designed to fit a variety of engine models, ensuring a secure and reliable connection for various fluid and gas lines. Here is a detailed look at the compatibility of this hose clamp with specific engine models:

B5.6 Series Engines

- B5.6 CM2670 B152B: This engine model benefits from the 5287716 hose clamp, which provides a tight seal for the coolant and fuel lines, ensuring optimal performance and preventing leaks.

B6.7 Series Engines

- B6.7 CM2350 B135B: The 5287716 hose clamp is compatible with this engine, offering a robust solution for securing the intake and exhaust hoses.

- B6.7 CM2670 B153B: This engine model also utilizes the 5287716 hose clamp, ensuring that all critical fluid and gas lines are securely fastened.

F3.8 Series Engines

- F3.8 F102: The 5287716 hose clamp is suitable for this engine, providing a reliable seal for the various lines that connect to the engine’s components.

ISF3.8 Series Engines

- ISF3.8 CM2220 AN: This engine model is designed to work with the 5287716 hose clamp, ensuring that the coolant and fuel lines are securely clamped.

- ISF3.8 CM2220 F103: The 5287716 hose clamp is also compatible with this engine, providing a dependable seal for the engine’s critical lines.

ISV (Nissan)

- ISV (Nissan): The 5287716 hose clamp is engineered to fit the ISV engine, ensuring that all fluid and gas lines are securely fastened, contributing to the engine’s overall performance and longevity.

Role of Part 5287716 Hose Clamp in Engine Systems

The Hose Clamp, identified by part number 5287716, is integral to maintaining the integrity and efficiency of various engine systems. It ensures secure connections in critical areas, allowing for optimal performance and reliability.

Compressor Air Inlet

In the compressor air inlet system, the Hose Clamp secures the connection between the air intake hose and the compressor. This ensures a tight seal, preventing air leaks that could reduce compressor efficiency and overall engine performance. The clamp’s role here is to maintain consistent air pressure and flow into the compressor, which is essential for the efficient operation of the air conditioning system.

Crankcase Breather System

Within the crankcase breather arrangement, the Hose Clamp is used to connect the breather tube to the crankcase and the vent hose assembly. This connection is vital for managing pressure within the crankcase, allowing gases to escape without causing damage or reducing engine efficiency. The clamp ensures that the breather system operates smoothly, preventing any buildup of harmful gases that could lead to engine wear or failure.

Plumbing and Vent Hose Assembly

In the broader plumbing and vent hose assembly, the Hose Clamp plays a key role in securing various hose connections. This includes attaching the vent hose to the crankcase breather and other components within the engine system. By providing a reliable seal, the clamp helps maintain the integrity of the vent system, ensuring that gases are properly directed away from the engine compartment. This is important for both engine performance and the overall safety of the vehicle.

Conclusion

Overall, the 5287716 is a fundamental component in ensuring that these engine systems operate efficiently and reliably. Its ability to create and maintain secure connections is essential for the proper functioning of the compressor, crankcase breather, and vent hose assembly.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.