This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

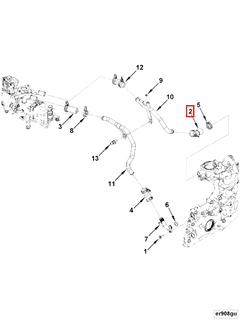

The Cummins 5289856 Molded Hose is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the transfer of fluids within the vehicle’s systems, ensuring efficient operation and reliability. This part is significant in maintaining the performance and longevity of truck systems by providing a durable and efficient means of fluid transport.

Basic Concepts of Molded Hoses

Molded hoses are manufactured by molding synthetic rubber or thermoplastic materials around a textile or wire reinforcement. This construction method enhances the hose’s flexibility, strength, and resistance to various environmental factors. Molded hoses are commonly used in automotive systems for their ability to withstand high pressure, temperature fluctuations, and corrosive fluids 1.

Purpose of the 5289856 Molded Hose

The 5289856 Molded Hose plays a specific role in the operation of a truck by connecting various systems and transporting essential fluids. It is typically used in the cooling system, where it facilitates the flow of coolant between the engine and the radiator. This ensures that the engine maintains an optimal operating temperature, preventing overheating and potential damage 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, including reinforced synthetic rubber, which provides excellent resistance to heat, pressure, and abrasion. The hose’s design includes smooth inner and outer surfaces to reduce flow resistance and prevent leaks. Additionally, it features precise fittings that ensure a secure connection to the systems it serves.

Benefits

The 5289856 Molded Hose offers several benefits compared to other types of hoses. Its robust construction and high-quality materials contribute to improved efficiency and reliability. The hose’s design reduces the risk of leaks and blockages, leading to enhanced system performance. Furthermore, its durability ensures a longer service life, reducing the need for frequent replacements.

Installation Considerations

When installing the 5289856 Molded Hose, it is important to follow specific guidelines and best practices to ensure proper function and longevity. The installation process may require specialized tools to secure the fittings and ensure a leak-free connection. It is also crucial to route the hose away from sharp edges and high-heat areas to prevent damage and maintain its integrity.

Troubleshooting Common Issues

Common problems associated with molded hoses include leaks and blockages. To troubleshoot these issues, it is important to inspect the hose for signs of wear, cracks, or abrasion. If a leak is detected, the hose should be replaced to prevent fluid loss and potential system failure. Blockages can often be resolved by flushing the hose with a compatible cleaning solution or replacing it if necessary.

Maintenance Tips

Regular maintenance of the 5289856 Molded Hose is essential to ensure optimal performance and longevity. This includes periodic inspection for signs of wear, leaks, or damage. It is also important to check the hose’s connections to ensure they remain secure and leak-free. Following the manufacturer’s recommended inspection intervals and care procedures will help maintain the hose’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of Part 5289856 Molded Hose in Engine Systems

Part 5289856, a molded hose, serves as a vital conduit within various engine systems, facilitating the efficient transfer of fluids and gases. Its application spans across several key components, ensuring optimal performance and reliability.

Plumbing Systems

In plumbing systems, the molded hose is instrumental in directing coolant flow. It connects the engine block to the radiator, allowing coolant to circulate and absorb heat generated by the engine. This continuous circulation helps maintain the engine’s operating temperature within safe limits, preventing overheating and potential damage.

Exhaust Recirculation

Within the Exhaust Gas Recirculation (EGR) system, the molded hose plays a significant role. It routes exhaust gases back into the intake manifold, reducing nitrogen oxide emissions. By diluting the intake charge with exhaust gases, the EGR system lowers combustion temperatures, which in turn reduces the formation of harmful emissions. The molded hose ensures a secure and leak-free connection between the exhaust and intake systems, maintaining the efficiency of the EGR process.

Water Systems

In water systems, particularly those involving water injection or cooling circuits, the molded hose is used to transport water or water-methanol mixtures. These systems rely on the hose to deliver the fluid precisely where needed, whether for additional cooling or performance enhancement. The hose’s durability and resistance to corrosion ensure long-term reliability in these applications.

Conclusion

The Cummins 5289856 Molded Hose is an essential component in the efficient operation of commercial truck systems. Its robust construction, high-quality materials, and precise design ensure reliable fluid transfer, contributing to the overall performance and longevity of the vehicle. Regular maintenance and proper installation are crucial to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.