This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

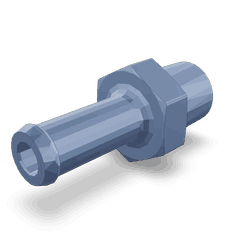

The Cummins 5365292 Plain Hose Coupling is a component designed for use in commercial truck operations. Its purpose is to facilitate the connection between hoses in fluid transfer systems, ensuring a secure and leak-free connection. This coupling is significant in maintaining the efficiency and reliability of fluid systems in commercial trucks.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect two hoses or a hose to a fitting without the need for clamps or additional fasteners. They function by compressing the hose between two flanges, creating a seal that allows for the transfer of fluids under pressure. These couplings are commonly used in various applications, including hydraulic systems, fuel lines, and coolant systems, where a secure and durable connection is required 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by providing a reliable connection in the truck’s fluid systems. It ensures that fluids such as hydraulic oil, fuel, or coolant are transferred efficiently and without leakage. This component is integral to maintaining the performance and safety of the truck’s systems, contributing to overall operational efficiency 2.

Key Features

The 5365292 is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically consisting of high-strength metals or durable polymers, which ensures resistance to wear and corrosion. The design elements of the coupling, such as the flanges and compression mechanism, are engineered to provide a secure seal under various pressure conditions. Additionally, any unique characteristics, such as anti-vibration properties or ease of installation, further contribute to its effectiveness in commercial truck applications 3.

Benefits

This part offers several benefits that contribute to improved efficiency, reliability, and ease of use in truck maintenance and operation. These benefits include reduced maintenance requirements due to its durable construction, enhanced safety through secure connections that prevent leaks, and simplified installation processes that save time and labor costs. Furthermore, the coupling’s design allows for quick disconnection and reconnection, facilitating easier maintenance and repair procedures 4.

Installation and Usage Guidelines

Proper installation and usage of the Plain Hose Coupling are vital to ensure optimal performance and longevity. The installation process involves selecting the appropriate coupling size for the hoses being connected, ensuring the hoses are clean and free from debris, and aligning the coupling correctly before tightening. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which can damage the hose or coupling. Regular inspection and maintenance, such as checking for signs of wear or leakage, are also recommended to prolong the life of the coupling.

Troubleshooting and Maintenance

Common issues that may arise with plain hose couplings include leaks, hose damage, or coupling misalignment. Troubleshooting these issues involves inspecting the coupling and hoses for visible signs of damage, ensuring proper alignment and connection, and checking for correct torque application. Maintenance practices to prolong the life of this Cummins part include regular inspection for wear and tear, cleaning the coupling and hoses to remove any debris or contaminants, and replacing the coupling if significant damage is detected. Adhering to these practices helps maintain the integrity and performance of the fluid transfer system.

Safety Considerations

When installing, maintaining, or troubleshooting the Plain Hose Coupling, it is important to observe several safety practices and precautions. These include wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses, ensuring the system is depressurized before beginning work to prevent injury from fluid spray, and following all manufacturer guidelines and recommendations. Additionally, being aware of the potential hazards associated with fluid transfer systems, such as high pressure and temperature, is crucial to maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted provider in the industry.

Cummins Engine Compatibility with Plain Hose Coupling Part 5365292

The Plain Hose Coupling part number 5365292, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral in ensuring the proper connection and functionality of hoses within the engine system, facilitating efficient fluid transfer and maintaining system integrity.

ISB5.9 CM2880 B127 and L9 CM2670 L128B Engines

The Plain Hose Coupling 5365292 is compatible with the ISB5.9 CM2880 B127 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The coupling ensures that hoses are securely attached, preventing leaks and maintaining the engine’s operational efficiency.

Similarly, the L9 CM2670 L128B engine also benefits from the use of the Plain Hose Coupling 5365292. This engine variant is designed for high-performance applications, and the coupling plays a crucial role in maintaining the integrity of the hose connections, which is vital for the engine’s smooth operation.

Grouping of Engines

Both the ISB5.9 CM2880 B127 and L9 CM2670 L128B engines fall under the category of high-performance, heavy-duty engines. The use of the Plain Hose Coupling 5365292 in these engines underscores its importance in ensuring that hose connections are reliable and secure, which is essential for the overall performance and longevity of the engine.

Role of Part 5365292 Plain Hose Coupling in Engine Systems

The part 5365292 Plain Hose Coupling is a component in ensuring the seamless operation of various engine systems. Its primary function is to facilitate secure and leak-free connections between different hoses and pipes within the engine’s fluid systems.

Connection

In engine systems, the Plain Hose Coupling is utilized to join hoses that transport fluids such as coolant, fuel, or hydraulic fluid. This component ensures that the connection is robust and resistant to vibrations, which are common in engine environments. By providing a reliable seal, it prevents fluid leaks that could lead to system failures or inefficiencies.

Water Inlet

At the water inlet of an engine, the Plain Hose Coupling plays a significant role in connecting the water pump to the engine block. This connection is vital for the circulation of coolant, which is necessary for maintaining optimal engine temperature. The coupling ensures that the coolant flow is uninterrupted, thereby protecting the engine from overheating.

Plumbing

Within the plumbing system of an engine, the Plain Hose Coupling is used to connect various components such as the radiator, thermostat housing, and heater core. Its design allows for easy installation and removal, which is beneficial during maintenance or repairs. The coupling’s ability to create a tight seal is essential for preventing coolant loss and ensuring efficient heat exchange.

Cabin Heater

The Plain Hose Coupling is also integral to the cabin heating system. It connects the hoses that carry hot coolant from the engine to the heater core inside the vehicle’s cabin. This connection ensures that the heater core receives a consistent flow of hot coolant, which is then used to warm the air blown into the cabin. The reliability of this connection directly impacts the comfort and safety of the vehicle’s occupants.

Conclusion

The Cummins 5365292 Plain Hose Coupling is a critical component in the maintenance and operation of commercial trucks and engines. Its design and features ensure secure, leak-free connections in fluid transfer systems, contributing to the efficiency, reliability, and safety of these systems. Proper installation, regular maintenance, and adherence to safety practices are essential to maximize the performance and longevity of this Cummins part.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.