This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

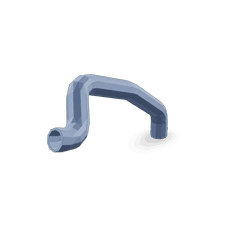

The 5541580 Molded Hose, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces this hose to meet the demanding requirements of heavy-duty applications. This part is integral to the fluid transfer systems in commercial trucks, ensuring efficient and reliable operation.

Basic Concepts of Molded Hoses

Molded hoses are specialized components used in fluid transfer systems. They are constructed by molding synthetic or natural rubber around a reinforcement material, which may include textile or steel wire. This construction provides the hose with the necessary flexibility and strength to withstand the pressures and temperatures encountered in automotive applications. Molded hoses function by conveying fluids such as coolant, fuel, or hydraulic fluid between different parts of a vehicle’s system 1.

Purpose of the 5541580 Molded Hose

This Cummins part is designed to play a specific role in the operation of a commercial truck. It is part of the fluid transfer systems, where it transports various fluids essential for the truck’s operation. The hose is engineered to connect critical components, ensuring the smooth and efficient transfer of fluids under varying conditions.

Key Features

The 5541580 incorporates several design and material characteristics that enhance its performance and durability. These include reinforced layers that provide structural integrity, heat resistance to withstand high operating temperatures, and flexibility to accommodate the dynamic movements of the truck’s components. These features contribute to the hose’s ability to perform reliably in demanding environments 2.

Benefits

Using this part offers several advantages. It provides improved reliability in fluid transfer operations, reducing the likelihood of leaks or failures. The hose’s design also contributes to reduced maintenance needs, as it is built to withstand the rigors of commercial truck use. Additionally, its robust construction enhances safety by minimizing the risk of fluid leaks, which can be hazardous 3.

Installation Considerations

Proper installation of the 5541580 is vital to ensure its effective performance. This includes conducting fitment checks to confirm the hose’s compatibility with the truck’s system, selecting the appropriate connection types for secure attachment, and ensuring a leak-free setup. Careful attention to these details during installation helps maintain the integrity of the fluid transfer system.

Troubleshooting Common Issues

Molded hoses, including the 5541580, may encounter issues such as leaks, cracks, or blockages over time. Identifying these problems early is important for maintaining system efficiency. Diagnostic approaches may involve visual inspections for physical damage, pressure testing to detect leaks, and flow checks to identify blockages. Repair or replacement may be necessary depending on the issue’s severity.

Maintenance Tips

Regular inspection and maintenance are key to prolonging the service life of the 5541580. This includes conducting visual checks for signs of wear or damage, performing pressure tests to ensure the hose remains leak-free, and adhering to recommended replacement schedules. These practices help maintain the hose’s performance and contribute to the overall reliability of the truck’s fluid transfer systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the needs of commercial and industrial applications. Cummins’ dedication to excellence is evident in its products, including the 5541580.

Cummins Molded Hose Part 5541580 Compatibility with Engine Models

The Cummins molded hose part number 5541580 is a critical component designed to fit seamlessly within various Cummins engine models. This hose is engineered to meet the stringent requirements of the QSK50, CM2350, and K108 engines, ensuring optimal performance and reliability.

QSK50 and CM2350 Engines

For the QSK50 and CM2350 engines, the molded hose part 5541580 is integral to the engine’s fluid management system. It is specifically designed to handle the high-pressure and high-temperature environments typical of these engines. The hose’s robust construction ensures it can withstand the rigors of continuous operation, providing a reliable connection for fluid transfer between various engine components.

K108 Engine

In the K108 engine, the molded hose part 5541580 plays a crucial role in maintaining the engine’s cooling system integrity. Its precise fit and durable material composition ensure that coolant flows efficiently, preventing overheating and maintaining the engine’s operational efficiency. The hose’s design also allows for easy installation and maintenance, reducing downtime and enhancing overall engine performance.

Grouping for Efficiency

When considering the QSK50 and CM2350 engines together, it is evident that the molded hose part 5541580 is engineered to handle similar fluid management tasks. This commonality allows for streamlined inventory management and ease of replacement, making it a preferred choice for operators managing fleets of these engines.

For the K108 engine, while the hose serves a specific function within the cooling system, its design and material properties ensure compatibility and performance across different operational conditions. This makes it a versatile component for maintaining the K108 engine’s efficiency and longevity.

Role of Part 5541580 Molded Hose in Crankcase Breather Arrangement

The 5541580 is integral to the efficient operation of the crankcase breather arrangement in engine systems. This hose facilitates the venting of gases from the crankcase, which is essential for maintaining optimal engine performance and longevity.

In the crankcase breather arrangement, the 5541580 connects the crankcase to the intake manifold or another suitable location in the engine’s air intake system. This connection allows for the safe and controlled release of gases, such as unburned fuel and combustion byproducts, that accumulate within the crankcase.

By directing these gases back into the intake system, the hose helps to reduce emissions and ensures that the engine operates within specified parameters. Additionally, this setup prevents the buildup of pressure within the crankcase, which could lead to oil leaks and other mechanical issues.

The 5541580 is designed to withstand the high temperatures and pressures associated with engine operation, ensuring reliable performance over the lifespan of the engine. Its role in the crankcase breather arrangement underscores the importance of proper ventilation in maintaining engine health and efficiency.

Conclusion

The 5541580 Molded Hose by Cummins is a critical component in the fluid transfer systems of commercial trucks, designed to meet the rigorous demands of heavy-duty applications. Its robust construction, heat resistance, and flexibility ensure reliable performance in demanding environments. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the hose’s service life and ensuring the efficient operation of the truck’s systems. Cummins’ commitment to quality and innovation is reflected in the design and functionality of this part, making it a valuable asset for commercial truck operators.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.