This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

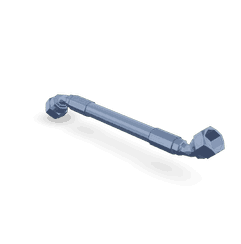

The Cummins 5547079 Flexible Hose is a specialized component designed for use in commercial truck systems. Its purpose is to facilitate the transfer of fluids within the truck’s various systems, ensuring efficient operation and reliability. This hose is integral to maintaining the functionality of critical systems by providing a flexible, durable connection that can withstand the rigors of heavy-duty applications.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and industrial systems to convey fluids such as coolant, fuel, oil, and hydraulic fluids. Unlike rigid pipes, flexible hoses can bend and twist without compromising the flow of fluids, making them ideal for applications where movement and vibration are common. They are constructed from materials that offer flexibility, durability, and resistance to the specific fluids they transport. Flexible hoses play a vital role in reducing stress on connected components, absorbing vibrations, and accommodating the dynamic movements within a vehicle’s system 1.

Purpose of the 5547079 Flexible Hose

The Cummins 5547079 Flexible Hose serves a specific role in the operation of commercial trucks. It connects various systems within the truck, such as the engine, transmission, and cooling system, facilitating the transfer of fluids essential for these systems’ operation. This hose is designed to transport fluids under varying pressure conditions, ensuring that the systems it connects function efficiently and reliably. By providing a flexible connection, it helps to mitigate the effects of engine and chassis movement, which is particularly important in heavy-duty applications 2.

Key Features

The Cummins 5547079 Flexible Hose boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer excellent resistance to the fluids it transports, as well as to environmental factors such as temperature fluctuations and chemical exposure. Its flexibility allows it to bend and twist without kinking or restricting fluid flow, while its durable construction ensures long-lasting performance even under demanding conditions. The design of the hose includes reinforced ends to prevent leakage and ensure a secure connection to fittings 3.

Benefits

Utilizing the Cummins 5547079 Flexible Hose offers several advantages. Its flexibility and durability contribute to improved system reliability by reducing the risk of leaks and failures associated with rigid hoses. The hose’s ability to absorb vibrations and accommodate movement within the truck’s systems helps protect connected components from stress and damage. Additionally, its robust construction ensures longevity, reducing the need for frequent replacements and maintenance 4.

Installation Considerations

When installing the Cummins 5547079 Flexible Hose, it is important to follow guidelines and best practices to ensure optimal performance. Proper fitting techniques are crucial to achieve a secure connection that prevents leaks. Alignment of the hose with the systems it connects should be carefully considered to avoid kinks or unnecessary stress on the hose. Securing the hose in place using appropriate clamps and supports is also important to maintain its position and flexibility over time 5.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, and degradation over time. To address these issues effectively, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the connection points should be checked for proper alignment and secure fitting. Kinks can often be resolved by rerouting the hose to avoid sharp bends. Degradation may require replacement of the hose to ensure continued system reliability 6.

Maintenance Tips

To prolong the lifespan of the Cummins 5547079 Flexible Hose, routine maintenance practices are recommended. Regular inspections should be performed to check for signs of wear, leaks, or damage. Cleaning the exterior of the hose can help remove contaminants that may accelerate degradation. Following manufacturer guidelines for replacement intervals is also important to ensure the hose remains in optimal condition. Proper storage and handling of the hose when not in use can further contribute to its longevity 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry 8.

Flexible Hose 5547079 in Cummins Engines

The Cummins Flexible Hose part number 5547079 is designed to integrate seamlessly with various Cummins engine models. This part is crucial for maintaining the integrity of the engine’s fluid systems, ensuring that connections between different components are both secure and flexible.

ISM CM876 Engines

In the ISM CM876 engine series, the Flexible Hose 5547079 is utilized to connect the engine’s fuel system components, ensuring that the fuel flow remains uninterrupted despite the engine’s movements. This hose is engineered to withstand the high pressures and temperatures typical in diesel engines, providing a reliable connection that can endure the rigors of continuous operation 9.

Group Compatibility

The Flexible Hose 5547079 is also compatible with other Cummins engine groups where similar fluid connection requirements exist. This includes applications in heavy-duty trucks and industrial machinery, where the engine’s movement and the need for robust fluid transfer are paramount. The hose’s design allows for flexibility, reducing stress on the engine’s components and preventing potential leaks or failures 10.

By integrating this hose into the engine’s design, Cummins ensures that the fluid systems within the engine can operate efficiently and reliably, contributing to the overall performance and longevity of the engine.

Role of Part 5547079 Flexible Hose in Turbocharger Plumbing

The part 5547079 Flexible Hose is integral to the turbocharger plumbing system, facilitating the transfer of exhaust gases from the engine to the turbocharger. This transfer is essential for the turbocharger to generate the compressed air required for efficient engine performance.

In the turbocharger plumbing, the flexible hose connects the exhaust manifold to the turbine housing of the turbocharger. This connection allows for the smooth and uninterrupted flow of exhaust gases, which spin the turbine wheel inside the turbocharger. The spinning turbine wheel, in turn, drives the compressor wheel, which compresses the intake air before it enters the engine’s combustion chambers.

The flexibility of the hose accommodates the relative movement between the engine and the turbocharger, which can occur due to thermal expansion and engine vibrations. This flexibility helps maintain a secure and leak-free connection, ensuring that the exhaust gases are effectively utilized to drive the turbocharger.

Additionally, the hose is designed to withstand high temperatures and pressures associated with exhaust gases, contributing to the overall durability and reliability of the turbocharger system. Its role in managing the flow of exhaust gases is fundamental to the efficient operation of the turbocharger, thereby enhancing the engine’s performance and power output 11.

Conclusion

The Cummins 5547079 Flexible Hose is a critical component in the operation of commercial trucks, ensuring the efficient transfer of fluids within various systems. Its flexibility, durability, and resistance to environmental factors make it an essential part of maintaining system reliability and performance. Proper installation, regular maintenance, and timely replacement are key to maximizing the benefits of this Cummins part, contributing to the overall efficiency and longevity of the truck’s systems.

-

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

engine: GTA38E G CMEICS G114 and GTA50E G CMEICS G115, Service Manual (5504185)

↩ -

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

Cummins Inc. Overview, Cummins Inc., 2024

↩ -

engine: GTA38E G CMEICS G114 and GTA50E G CMEICS G115, Service Manual (5504185)

↩ -

Cummins Inc. Overview, Cummins Inc., 2024

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.