3927317

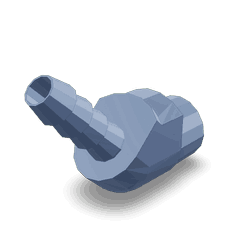

Elbow Hose Coupling

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Elbow Hose Coupling, part number 3927317, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This coupling is designed to facilitate the connection between hoses in fluid systems, ensuring a secure and efficient transfer of fluids within the truck’s operational framework.

Basic Concepts of Elbow Hose Couplings

Elbow hose couplings are fittings used to join hoses at an angle, typically 90 degrees, allowing for a change in direction of fluid flow within a system. They are integral to fluid systems, providing flexibility and ease of installation in tight spaces. In commercial trucks, these couplings are commonly used in various systems, including coolant, fuel, and hydraulic lines, where changes in direction are necessary to navigate the complex layout of the vehicle’s undercarriage 1.

Purpose of the 3927317 Elbow Hose Coupling

The 3927317 Elbow Hose Coupling by Cummins is specifically engineered to play a role in the fluid systems of commercial trucks. It ensures a reliable connection between hoses, maintaining the integrity of fluid flow throughout the system. This coupling is vital for the consistent operation of the truck, as it helps prevent leaks and ensures that fluids are delivered efficiently to their intended destinations 2.

Key Features

The 3927317 Elbow Hose Coupling boasts several key features that enhance its performance and durability. Constructed from high-quality materials, it is designed to withstand the rigors of commercial truck environments. Its design includes precision-machined surfaces for a secure fit, corrosion-resistant properties to extend lifespan, and a robust construction that can handle high-pressure applications. Additionally, the coupling features easy-to-use clamps that simplify installation and removal, contributing to its overall efficiency 3.

Benefits

Utilizing the 3927317 Elbow Hose Coupling in truck systems offers several advantages. Its durable construction and reliable performance contribute to improved system efficiency and reliability. The coupling’s design reduces the likelihood of leaks, ensuring that fluid systems operate at optimal levels. Furthermore, its ease of installation and maintenance makes it a practical choice for fleet managers and technicians 4.

Installation Considerations

When installing the 3927317 Elbow Hose Coupling, it is important to follow guidelines to ensure a secure and efficient connection. The process involves preparing the hose ends, aligning the coupling, and securing it with the provided clamps. Tools required may include hose cutters, a deburring tool, and a torque wrench for tightening the clamps. Careful attention to the manufacturer’s instructions can help avoid common pitfalls, such as over-tightening or misalignment, which could compromise the coupling’s performance.

Troubleshooting Common Issues

Common issues with the 3927317 Elbow Hose Coupling may include leaks or connection failures. These can often be traced back to improper installation, wear and tear, or environmental factors. Addressing these issues involves inspecting the coupling for signs of damage, ensuring that clamps are properly tightened, and replacing any worn or damaged components. Regular maintenance and inspections can help identify potential problems before they lead to system failures.

Maintenance Tips

To ensure the longevity and optimal performance of the 3927317 Elbow Hose Coupling, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the coupling and its surrounding areas can prevent the buildup of debris that might affect its operation. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain system integrity and efficiency.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements have made it a preferred choice for fleet operators and maintenance professionals worldwide.

Compatibility of Elbow Hose Coupling Part 3927317 with Cummins Engines

The Elbow Hose Coupling part number 3927317, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This coupling is essential for maintaining the integrity of the engine’s cooling and exhaust systems by providing a secure connection between hoses and engine components.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, both part of the Cummins B Series, are commonly used in various industrial and commercial applications. The 3927317 Elbow Hose Coupling is engineered to fit these engines, ensuring a reliable connection that can withstand the operational stresses of these robust engines. This coupling is particularly useful in applications where precise hose alignment is critical for optimal engine performance.

6C8.3 Engine

The 6C8.3 engine, another member of the Cummins C Series, benefits from the 3927317 Elbow Hose Coupling. This engine is known for its durability and efficiency, often used in heavy-duty applications. The coupling’s design ensures that it can handle the high pressures and temperatures associated with the 6C8.3 engine, providing a long-lasting and dependable connection.

ISB6.7 G CM2180 B118 and ISL G CM2180 Engines

The ISB6.7 G CM2180 B118 and ISL G CM2180 engines are part of the Cummins ISB and ISL Series, which are widely recognized for their power and reliability in both on-highway and off-highway applications. The 3927317 Elbow Hose Coupling is compatible with these engines, ensuring that hose connections remain secure and leak-free, even under the most demanding conditions.

Each of these engines, despite their differences in size and application, relies on the 3927317 Elbow Hose Coupling to maintain the integrity of their respective systems. This coupling’s design and material quality make it a versatile and essential component for these Cummins engines.

Role of Part 3927317 Elbow Hose Coupling in Engine Systems

The 3927317 Elbow Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of hoses in critical pathways.

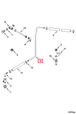

In the Aftercooler Plumbing Kit, the Elbow Hose Coupling ensures a tight seal between the aftercooler and the associated piping, allowing for the effective cooling of compressed air before it enters the engine. This helps in maintaining optimal engine performance and longevity.

Within the Air Fuel Control Plumbing system, the coupling is used to connect different sections of the plumbing, ensuring that the air-fuel mixture is delivered consistently and without leaks. This is particularly important for maintaining the correct air-fuel ratio, which is vital for combustion efficiency.

For the Air Fuel Control Tube, the Elbow Hose Coupling provides a necessary bend in the hose routing, accommodating the complex layout of engine compartments while ensuring that the air supply remains uninterrupted.

In the Engine Installation Kit, this component plays a role in connecting various hoses that are part of the engine’s ancillary systems, such as coolant or lubrication lines, ensuring that all connections are secure and leak-free during and after installation.

The Fuel Control system benefits from the Elbow Hose Coupling by ensuring that fuel lines are properly connected, allowing for precise fuel delivery to the engine. This is important for both performance and safety, as any leaks in the fuel system can lead to dangerous situations.

Similarly, in the Fuel Control Module, the coupling ensures that all fuel lines are correctly and securely attached, contributing to the module’s ability to regulate fuel flow accurately.

Lastly, in Turbocharger Plumbing, the Elbow Hose Coupling is used to connect the various hoses that route air to and from the turbocharger. This ensures that the turbocharger receives a consistent airflow, which is essential for its efficient operation and the overall performance of the engine.

Overall, the 3927317 Elbow Hose Coupling is a versatile component that enhances the reliability and efficiency of various engine systems by providing secure and leak-free connections.

Conclusion

The 3927317 Elbow Hose Coupling by Cummins is a critical component in the fluid systems of commercial trucks and various Cummins engines. Its design, durability, and ease of installation make it a reliable choice for maintaining the integrity of fluid connections in demanding environments. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this component.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.