This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3927732 Elbow Hose Coupling, manufactured by Cummins, is a specialized component designed for commercial truck applications. Cummins is renowned for its robust and reliable parts, and this Cummins part is significant in maintaining the efficiency and reliability of fluid transfer systems in trucks.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid within a system. These couplings are integral to fluid systems, allowing for flexible and secure connections that can withstand various pressures and environmental conditions. In a truck’s subsystems, elbow hose couplings enable the routing of fluids around obstacles and through tight spaces, ensuring smooth operation and reducing the risk of leaks 1.

Purpose of the 3927732 Elbow Hose Coupling

The 3927732 Elbow Hose Coupling is designed to facilitate the transfer of fluids in systems such as coolant, fuel, or hydraulic lines. Its angled design allows for efficient fluid flow while navigating the complex layout of a truck’s engine compartment. This coupling ensures that fluids are directed precisely where needed, contributing to the overall performance and reliability of the truck’s systems 2.

Key Features

The 3927732 Elbow Hose Coupling boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The coupling features a secure connection type that maintains integrity under high pressure, with specified pressure ratings that meet the demands of commercial truck applications. Its design characteristics include reinforced fittings and precise engineering to ensure a leak-free connection 3.

Benefits

Using the 3927732 Elbow Hose Coupling offers several advantages. It contributes to improved system efficiency by ensuring a consistent and reliable fluid transfer. The design reduces the risk of leakage, which is critical in maintaining system performance and safety. Additionally, the coupling’s durable construction enhances its longevity, while its ease of installation simplifies maintenance and repair processes.

Installation Process

Proper installation of the 3927732 Elbow Hose Coupling involves several steps to ensure a secure and efficient fit. Begin by gathering the necessary tools, such as wrenches and hose clamps. Prepare the hoses by cleaning the ends and ensuring they are free of debris. Align the coupling with the hoses and connect them, tightening the fittings to the specified torque. Verify the connection by checking for leaks and ensuring there is no undue stress on the hoses or coupling.

Troubleshooting Common Issues

Common issues with elbow hose couplings include leaks, corrosion, and connection failures. To address these problems, first identify the source of the issue. For leaks, inspect the connections and fittings for signs of wear or damage. Corrosion can be mitigated by using couplings made from corrosion-resistant materials and regularly inspecting for signs of degradation. Connection failures may require re-tightening or replacing the coupling if damage is detected.

Maintenance Tips

Regular maintenance of the 3927732 Elbow Hose Coupling is vital to prolong its lifespan. Inspect the coupling routinely for signs of wear, corrosion, or leaks. Clean the coupling and surrounding areas to prevent the buildup of debris that could cause damage. If significant wear or damage is detected, consider replacing the coupling to ensure continued system reliability. Following these maintenance practices will help maintain the efficiency and safety of the truck’s fluid transfer systems.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a rich history of innovation and quality. The company offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins is renowned for its commitment to producing high-quality, durable parts that meet the demanding requirements of the trucking industry.

Compatibility of Elbow Hose Coupling Part 3927732 with Cummins Engines

The Elbow Hose Coupling part 3927732, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral in ensuring a secure and leak-proof connection between hoses and engine components, facilitating efficient fluid transfer and maintaining system integrity.

Cummins 4B3.9 and QSB3.9 30 CM550 Engines

The 4B3.9 and QSB3.9 30 CM550 engines are part of Cummins’ smaller displacement lineup, typically used in compact machinery and light-duty applications. The 3927732 elbow hose coupling is compatible with these engines, providing a reliable connection for coolant and other fluid lines.

Cummins 6B5.9 and QSB5.9 30 CM550 Engines

The 6B5.9 and QSB5.9 30 CM550 engines represent a mid-range displacement series, often found in medium-duty vehicles and industrial equipment. The 3927732 elbow hose coupling is engineered to fit these engines, ensuring robust connections for high-pressure fluid lines.

Cummins 6C8.3 and QSB5.9 44 CM550 Engines

The 6C8.3 and QSB5.9 44 CM550 engines are higher displacement models, commonly used in heavy-duty trucks and large industrial machinery. The 3927732 elbow hose coupling is designed to handle the demanding conditions of these engines, providing a durable and secure connection for critical fluid lines.

Cummins B4.5, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, L GAS PLUS CM556, and L8.9G CMOH2.0 L125B Engines

These engines, including B4.5, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, L GAS PLUS CM556, and L8.9G CMOH2.0 L125B, are part of Cummins’ gas engine lineup, used in a variety of applications from agricultural equipment to marine vessels. The 3927732 elbow hose coupling is compatible with these engines, ensuring reliable connections for fuel, coolant, and other fluid lines.

Cummins ISB CM550, ISB5.9G CM2180, and ISL G CM2180 Engines

The ISB CM550, ISB5.9G CM2180, and ISL G CM2180 engines are part of Cummins’ diesel engine series, widely used in heavy-duty trucks, construction equipment, and industrial applications. The 3927732 elbow hose coupling is designed to fit these engines, providing a secure and leak-proof connection for high-pressure fluid lines.

Each of these engines, despite their varying applications and power outputs, relies on the 3927732 elbow hose coupling to maintain efficient and reliable fluid transfer, ensuring optimal performance and longevity.

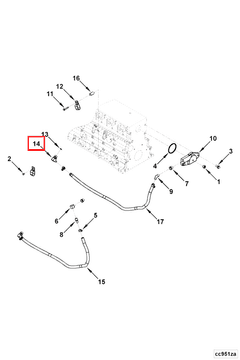

Role of Part 3927732 Elbow Hose Coupling in Engine Systems

The 3927732 Elbow Hose Coupling is an integral component in the efficient operation of engine systems, particularly in the context of compressor coolant arrangements and plumbing. This part facilitates the secure and reliable connection between hoses in the coolant system, ensuring that the coolant flow is maintained without leaks or disruptions.

In the compressor coolant system, the Elbow Hose Coupling is positioned at strategic points where hoses need to change direction. This allows for a smooth transition in the coolant flow path, minimizing resistance and ensuring that the compressor receives a consistent supply of coolant. The coupling’s design helps in accommodating the spatial constraints often found in engine compartments, making it possible to route hoses around other components without compromising the integrity of the coolant system.

Within the broader plumbing of the engine, the 3927732 Elbow Hose Coupling plays a significant role in maintaining the overall arrangement of hoses. It contributes to the organized layout of the coolant system, which is essential for both the aesthetic and functional aspects of engine maintenance. The coupling ensures that hoses are securely fastened, reducing the risk of disconnections that could lead to coolant loss and subsequent engine overheating.

Overall, the 3927732 Elbow Hose Coupling is a key element in the seamless integration of hoses within engine systems, supporting the reliable operation of the compressor coolant system and the efficient plumbing of the engine.

Conclusion

The 3927732 Elbow Hose Coupling is a critical component in the fluid transfer systems of commercial trucks, ensuring efficient and reliable operation. Its robust design, compatibility with various Cummins engines, and ease of installation make it an essential part for maintaining the performance and longevity of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this coupling.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.