This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

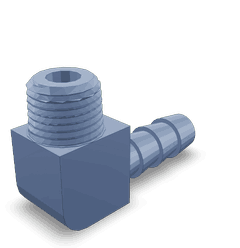

The 3928533 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to the truck’s fluid systems, facilitating the transfer of various fluids essential for the vehicle’s operation. This coupling allows for efficient fluid transfer by connecting hoses at an angle, which is often necessary in the complex layout of a truck’s fluid system.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees. Its function is to provide a secure and leak-proof connection in fluid systems. These couplings can handle a variety of fluids, including coolants, fuel, and hydraulic fluids, and are designed to withstand the demanding environments found in commercial trucking, such as exposure to vibrations, temperature fluctuations, and chemical exposure 1.

Purpose of the 3928533 Elbow Hose Coupling

The 3928533 Elbow Hose Coupling is specifically designed to play a role in the fluid systems of trucks by enabling the connection of hoses at an angle. This design ensures that fluid transfer is efficient and uninterrupted, even when the hoses cannot be aligned in a straight line. The coupling’s angled connection is particularly useful in navigating the tight spaces and complex routing required in truck fluid systems.

Key Features

The 3928533 Elbow Hose Coupling boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-lasting performance. The coupling features a secure connection type that minimizes the risk of leaks, and it is rated to handle specific pressure levels, making it suitable for various fluid systems. Its design includes attributes that facilitate easy installation and maintenance, contributing to its overall effectiveness in truck applications.

Benefits

Using the 3928533 Elbow Hose Coupling in truck fluid systems offers several advantages. It improves fluid flow by providing a reliable connection that reduces the risk of leaks. The coupling’s design also makes it easier to install and maintain, which can save time and reduce the need for frequent repairs. Additionally, its durable construction contributes to the overall reliability of the truck’s fluid systems.

Installation Considerations

When installing the 3928533 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure a secure and efficient connection. This may include adhering to torque specifications to avoid over-tightening, which can damage the coupling, and ensuring proper alignment to facilitate smooth fluid transfer. Compatibility with other system components should also be considered to maintain system integrity 2.

Troubleshooting Common Issues

Common problems associated with elbow hose couplings can include leaks, connection failures, and material wear. Troubleshooting these issues may involve inspecting the coupling for signs of damage, ensuring that it is properly installed, and checking for compatibility with the fluids and pressures in the system. Regular maintenance can help prevent these issues and ensure the coupling’s longevity.

Maintenance Tips

To maintain the 3928533 Elbow Hose Coupling and ensure its optimal performance, regular inspection routines should be established. This may include checking for signs of wear or damage, cleaning the coupling to remove any buildup that could affect its function, and replacing it when necessary. Following these maintenance tips can help extend the life of the coupling and maintain the efficiency of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the 3928533 Elbow Hose Coupling, which is designed to meet the demanding requirements of commercial truck applications.

Compatibility of Elbow Hose Coupling Part 3928533 with Cummins Engines

The Elbow Hose Coupling part 3928533, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for ensuring a secure and leak-proof connection between hoses and engine components. Below is a detailed breakdown of the engines that are compatible with this part:

Group 1: B Series Engines

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB5.9G CM2180

Group 2: C Series Engines

- C GAS PLUS CM556

- C8.3 G

Group 3: G Series Engines

- G8.3

- L GAS PLUS CM556

Group 4: ISB Series Engines

- ISB5.9G CM2180

- ISB6.7 G CM2180 B118

Group 5: ISG and ISX Series Engines

- ISG12 G CMOH6.0 G111

- ISX12 G CM2180 EJ

Group 6: L Series Engines

- L8.9G CMOH2.0 L125B

Group 7: X Series Engines

- X12N CMMDG1 X143B

Each of these engines, despite their differences in power output and specific applications, can utilize the Elbow Hose Coupling part 3928533 for maintaining the integrity of their hose connections. This part is engineered to provide a reliable fit across these diverse engine models, ensuring that the connection remains secure under various operating conditions.

Role of Part 3928533 Elbow Hose Coupling in Engine Systems

The 3928533 Elbow Hose Coupling is a pivotal component in various engine systems, facilitating the secure and efficient transfer of fluids and gases. Its application spans across multiple subsystems, ensuring optimal performance and reliability.

Aftercooler Plumbing Kit

In the aftercooler plumbing kit, the Elbow Hose Coupling is employed to redirect the flow of cooled air from the aftercooler to the air intake system. This redirection is essential for maintaining the integrity of the air supply, ensuring that the air entering the engine is at the desired temperature and pressure.

Air Connection and Air Intake Connection

For air connections and air intake connections, the Elbow Hose Coupling serves as a vital link. It allows for the precise angling of hoses, accommodating the complex geometry of engine compartments. This ensures a snug fit and prevents leaks, which could otherwise compromise engine efficiency.

Air Fuel Control Plumbing and Air Fuel Mixer

Within the air fuel control plumbing and air fuel mixer, the Elbow Hose Coupling plays a role in managing the mixture of air and fuel. By providing a flexible connection point, it enables the system to adapt to the dynamic requirements of the engine, ensuring a consistent and optimal air-fuel ratio.

Engine Cooling System

In the engine cooling system, the Elbow Hose Coupling is used to connect various components such as the radiator, water pump, and thermostat housing. Its ability to handle high temperatures and pressures makes it suitable for this application, ensuring efficient coolant flow and engine temperature regulation.

Engine Installation Kit

During engine installation, the Elbow Hose Coupling is often included in the installation kit to simplify the connection of various hoses and pipes. Its design allows for easy installation and removal, reducing the time and effort required during engine maintenance or replacement.

Fuel Control and Fuel Control Module

For the fuel control and fuel control module, the Elbow Hose Coupling ensures a secure connection between the fuel lines and the module. This is important for maintaining the precise delivery of fuel to the engine, which is critical for performance and emissions control.

Fuel Pressure Regulator

In conjunction with the fuel pressure regulator, the Elbow Hose Coupling helps maintain consistent fuel pressure within the system. Its robust construction ensures that it can withstand the high pressures involved in fuel delivery, contributing to the overall reliability of the fuel system.

Turbocharger Arrangement and Turbocharger Location

In turbocharger arrangements, the Elbow Hose Coupling is used to connect the turbocharger to the intake and exhaust systems. Its flexibility allows for optimal positioning of the turbocharger, enhancing its efficiency and performance. At the turbocharger location, it ensures a secure and leak-free connection, which is essential for the turbocharger to function correctly.

Turbocharger Plumbing

Finally, in turbocharger plumbing, the Elbow Hose Coupling is integral to the system. It allows for the precise routing of exhaust gases to the turbocharger and the subsequent delivery of compressed air to the engine. This ensures that the turbocharger operates within its designed parameters, maximizing engine performance and efficiency.

Conclusion

The 3928533 Elbow Hose Coupling is a critical component in the fluid systems of commercial trucks, offering a reliable and efficient solution for connecting hoses at an angle. Its robust construction, ease of installation, and maintenance make it a valuable asset for ensuring the smooth operation of truck fluid systems. By understanding its features, benefits, and proper installation and maintenance practices, truck operators and maintenance personnel can ensure the longevity and efficiency of this Cummins part in their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.